How to insert a spring into a chainsaw starter

Chainsaw starter repair (broken spring)

Simple Chainsaw Repair for Beginners Own Hands.

Chainsaw starter: device, breakdowns and DIY repairs

In the design of the chainsaw, the starter is responsible for the proper starting of the engine of the tool. Over time, owners of chainsaws are faced with the need to repair this important unit. And, the sooner it is possible to eliminate the malfunction, the less other important parts and mechanisms of the tool will succumb to wear.

Practical advice

You may need to make a few more turns to match the cord retention holes in the pulley and housing. A new rope is threaded through a technological hole and a loop or knot is made: this will allow it to slip out of the pulley. The rope is taken to the side so that it does not interfere with further work. Next, you need to fix the pulley.

First you need to reinstall the soft start spring. It can be used the old one if no damage is found in it. or a new one if necessary. A starter clamp is installed on top of the spring, which is fixed with a special screw. It reliably fixes the clamp for a long time, preventing it from skewing and swinging. After that, you need to make several turns of the rope and run it inside. The cover with the assembled starter is installed in place. With the help of screws, it is fixed.

After the completion of the repair and assembly, you can start working. how to properly lubricate the chain how to shorten the chain on mtb chainsaw starter repair. Self-repair of a starter does not take much time and does not require complex skills, but it saves time and money if you perform such work in a service center.

It is necessary to approach the repair of a chainsaw responsibly and carry out preventive inspections in a timely manner, monitor the quality of the fuel and oil used. These simple manipulations will increase the duration of the tool in working condition.

How to bend a spring on a chainsaw starter

Typical malfunctions

The more common tool breakdowns include the following:

- obstructions in the ignition system;

- stopping the chainsaw in the process of cutting;

- loss of power during operation;

- wear of some structural parts of the chainsaw (brake band, drive sprockets, anti-vibration parts);

- obstructions in the fuel supply system;

- malfunctions associated with the starter.

Echo Chainsaw Rewind Spring Replacement #P022001330

In addition, you need to create a visual inspection of the chainsaw before work and preventive measures. How to wind the grass trimmer starter spring the starter cable does not unwind: how to find out the cause and repair the starter with your own hands? How to disassemble the starter, stick it in again. These include chain lubrication, control of the amount of fuel mixture, and the availability of the required amount of oil.

The spark plug is removed to check its condition.

Any of the defects is eliminated using our own technology. So, for example, repairing the fuel system of a chainsaw should begin with an inspection of the corresponding filter. After that, the correctness of the carburetor regulation, which is carried out with the help of screws, is inspected. Clearances must be set in strict accordance with the manufacturer’s annotation, which must be supplied with the chainsaw. The repair of the ignition system includes inspections of the spark plugs. If a strong carbon deposit, a change in the gap or other visible damage is found, this element must be replaced.

Spring renovation

If the starter spring material was not of good quality, the spring breaks (usually at the point where it joins the drum where it forms a loop). In this case, it is not worth replacing the spring. It is enough to thoroughly clean the surface from dirt and grease, carefully polish the damaged area, and then release the spring at 600.650 ° C (steel springs should turn crimson). It is necessary to slowly cool the spring and at 100.150 ° C it is already possible to carefully wrap its end in the form of a restrictive protrusion on the inner surface of the drum (steel acquires the necessary plasticity) and insert it into place. The elastic properties of the spring will not change.

With frequent starting of the chainsaw, some parts of the starter are constantly subjected to dynamic loads. As a result, the cable can break, several shaking teeth can collapse, and the shaft rotates at a much slower speed. Therefore, the revision and even repair of the starter. these are operations that are sometimes performed several times per season.

Typical breakdowns and repairs of the chainsaw starter

The appearance of various malfunctions of the starter leads to the inability to start the chainsaw. The most common starter breakdowns include:

- The starter pulley is completely burst or cracked;

- The spring has burst;

- Starter rope broke.

To fix each of these faults with your own hands, you will need certain tools. You must have a set of screwdrivers and a spare cable with you. It is necessary to remove and inspect the starter for the chainsaw in the following order:

- To find the cause of the breakdown, the starter will need to be removed from the chainsaw. To do this, unscrew the screws with a screwdriver, with which the protective cover with the starter attached to it is held;

- After removing the cover, you must carefully unscrew the screw by means of which the starter is attached to the protective cover;

- Then you need to try to smoothly start the starter. for this, remove the spring and clamps from it;

- Further, a coil with a cable is removed from the starter for inspection.

As a result of inspection, you can find a number of typical malfunctions. These include:

- Various damage to the pulley in the form of ruptures or cracks, mainly in the rear of the part. they interfere with the normal operation of the entire starter;

- Damage to the starter spring of the lightweight start. in such cases, not only the spring itself can be faulty, but also the place of its fixation. this is the most vulnerable part of the spring;

- Damaged starter flywheel dog.

In any case, any defective part must be completely replaced with a new part.

Typical breakdowns and repairs of the chainsaw starter

Before carrying out repairs, it is necessary to find out the reasons for the breakdown. Since the product is constantly subjected to dynamic and other types of loads, its failure is not excluded. Frequent causes of starter breakdowns are: cable breakage, abrasion or chipping of several splines of the ratchet drum, damage to the spring, cracked pulley and others. To determine why the saw will not start, you will need to conduct an appropriate revision of the starter mechanism. Consider the main types of malfunctions, as well as find out how to properly repair the product.

How to replace a chainsaw starter spring?

In order to replace the old spring in the disassembled starter, you must proceed in the following order:

- Before installing the chainsaw starter spring, you will need to remove the mechanism clip. this should be done very carefully so as not to break the part;

- Then you need to look inside the clip. in it you will see a spring wrapped around a C-shaped element. To remove the spring, fix its upper part with your finger and pull the starter handle slightly to the side;

- After removing the old spring, you need to wind up a new part. At the same time, try to avoid kinking and twisting of the new spring element;

- To collect the chainsaw starter spring, you will need to act as carefully as possible, otherwise one wrong movement can lead to unwinding of the part;

- After you have managed to fully insert the spring into the starter, you must carefully fix the clip.

How to repair a trimmer starter

The gasoline grass trimmer starter may need to be repaired at the most inopportune moment. You can solve the problem in two ways: replace a broken part or change the entire assembly. The latter option will cost more. To repair the device yourself, in most cases you only need a screwdriver with an appropriate tip from the tools. Repair work does not require much time and does not require special knowledge. It is enough to know the device, the principle of operation, the nuances of assembling and disassembling the starter on the trimmer in order to achieve the desired positive result.

The first option is much more common.

The starter motor works without breakage for a long time. It cannot unequivocally indicate the period of uptime. Everything is determined by the initial quality of the device and the observance of the rules for its processing.

The Brovchenko family. Installing the spring in the recoil starter of the lawn mower.

How to install a spring in a recoil starter for a petrol trimmer? It is possible to do this at home. To me

Removal and dismantling of the starter, replacement of broken parts

To repair the grass trimmer starter, you need to disassemble it first and then reassemble it. This process is not particularly difficult. You will need to work a screwdriver with the desired tip shape.

Everything should be done carefully, observing safety precautions, mainly that the spring does not damage the master in the event of an accidental flight.

Starter Assembly Analysis

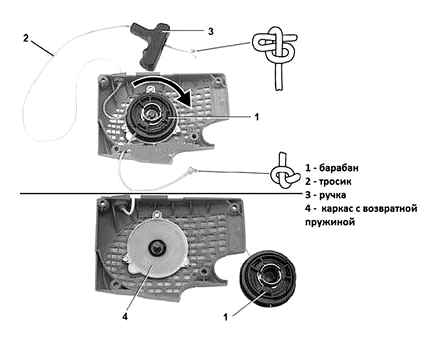

Disassemble the trigger mechanism to replace the broken parts in the following sequence:

- unscrew the screw blocking the pulley with the starter cover with a screwdriver;

- remove the spring and antennas;

- carefully remove the pulley (you must at the same time turn your head or work, wearing glasses and gloves);

- determine why the trigger mechanism has broken;

- if the spring is almost completely destroyed, then it is replaced;

- when the spring leaves the hook, it is placed in its original place, bending the antennas in front of it (photographs show the laying process);

- After the spring plate is inserted into the groove, twist it gently.

How to put a spring on a chainsaw starter?

Fitting the spring into the correct groove is a tricky task. First of all, the part will need to be twisted, returning it to its previous dimensions. After that, it must be inserted into the cavity of the standard drum hub. To fill the spring in the chainsaw starter, you need to proceed in this order:

- The outer end of the spring used must be fixed in a special stop lug. In this case, the second end with a screwdriver will need to be installed opposite the standard hole inside the lock;

- Next, the loop located at the inner end of the standard spring should be aligned with the hole. It is better to use a screwdriver for this. When the ends are aligned, the disc will need to be lowered;

- After mounting the disc, you need to check that the dog of the factory ratchet mechanism of the chainsaw is in its regular place. Then you can assemble the ratchet in reverse order.

To wind the spring on the chainsaw starter, you need to take into account all the holes and notches available. After installation, you will need to tighten the spring. As soon as the slack is eliminated, the spring will remain to be wound a few turns. this is necessary to maintain the required tension of the installed part.

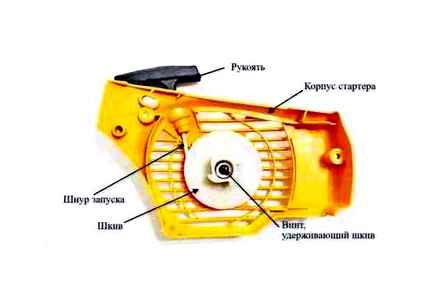

Chainsaw starter device

As standard, the chainsaw starter consists of a number of parts.

- coil;

- cable;

- the frame to which the return spring is attached;

- a pen.

A protective cover is installed on top of all elements of the starter. The original principle of operation of most triggers is also almost the same. In a special groove in the chainsaw body there is a handle that holds the cable. When the handle is raised sharply, the latter is understood. At this moment, a ratchet is triggered, which, through the drum, transfers the force to another drum with splines located on the engine shaft.

How To Assemble A Recoil Starter System. TreeStuff.com Chainsaw Maintenance Video

When pulling out the standard cable, the chainsaw motor shaft begins to rotate, which leads to compression of the existing fuel mixture located at this time between the cylinder head and the standard piston.

With an increase in the volume of the internal combustion engine cylinder, the amount of consumed fuel mixture, which is required for its future ignition, also increases. Consequently, the operator of a powerful saw needs more jerking strokes than the owner of a low power tool. Powerful chainsaw manufacturers use resilient return springs to increase the speed at which the drum returns to its original position.

How to repair a chainsaw starter with your own hands

The article presents the repair of a chainsaw starter after a break in the starting cord. Without a starting cord, the chainsaw becomes completely inoperative, there is no other way to start the tool. The repair was examined using the example of the Partner P350S chainsaw, a tricky reliable start of this saw requires at least 4-5 pulls on the starting cord for the saw to work, so, probably, the first malfunction was in the cord break. The cord does not break immediately, first the protective stocking of the cord threads breaks and prevents the saw from starting. It is better not to wait for all the threads to break and fix the cord in advance. It is not necessary to invent anything, repairs should not cause difficulties, but exact observance of the assembly conditions is necessary. A step-by-step instruction with a scheme of actions with photos and videos is given below.

We unscrew the three screws securing the starter cover. The included spark plug wrench with a straight screwdriver is fine for this process, but to speed up the work it is better to use a normal tool.

We remove the starter. The chainsaw is equipped with a soft-start mechanism, it is located above the cord reel.

We unscrew the screw that secures the soft start mechanism and the starter coil. Be careful not to lose the washer!

The chainsaw is an indispensable tool not only for the summer resident, but also during construction work. If you need to stock up on firewood for the winter, then going into the forest without a chainsaw does not make sense at all. With proper use of the tool, it can last for a long time, but in any case, sooner or later, various types of malfunctions will arise. One of these malfunctions is a breakdown of the starter, as a result of which it becomes difficult to start the engine. In this situation, it is advisable to repair the chainsaw starter with your own hands. How to do this, we will find out in the material.

Typical breakdowns and repairs of the chainsaw starter

Before carrying out repairs, it is necessary to find out the reasons for the breakdown. Since the product is constantly subjected to dynamic and other types of loads, its failure is not excluded. Frequent causes of starter breakdowns are: cable breakage, abrasion or chipping of several splines of the ratchet drum, damage to the spring, cracked pulley and others. To determine why the saw will not start, you will need to conduct an appropriate revision of the starter mechanism. Consider the main types of malfunctions, as well as find out how to properly repair the product.

How to replace a chainsaw starter spring

If the spring is damaged, which is often the case on Chinese instruments, then the mechanism can only be repaired by replacing it. But if its damage occurred at the point of attachment, that is, the ear burst, then it can be repaired.

The repair of the spring is heating the place of destruction to 600 degrees, after which it slowly cools down to 100 degrees, at which the end is wrapped in the shape of a fragment. Thus, it will be possible to avoid the loss of elasticity of the product, which will extend its service life. Although most specialists simply replace the product with a new one.

The spring replacement process is carried out in the following sequence:

- Initially, the clip or drum of the mechanism is removed.

- There is a spring inside the drum. To dismantle it, you will need to fix its upper part, then pull the starter handle aside.

- When the old spring is removed, you will need to install a new one. In this case, it is imperative to clean the case.

- When installing a new spring, insert it into the starter, then hit the groove with a tendril.

- At the end of the work, you can put on the drum and replace the starter cover.

See the detailed spring replacement process at

Replacing the cord

The starter cord is a strong rope that is strong enough to wear out, but even its technical properties do not save it from damage. The rope rubs against the body of the starter cover every time the tool is started, which leads to its gradual chafing and wear.

If the cord is frayed, then to replace it, you will need to disassemble the body of this unit. After removing the cover, it is necessary to lift the drum, but only in such a way that it does not jump out of its seats. It is recommended to carry out this work together with a partner who will fix the spring, and you will take over the replacement of the cable. The remnants of the old cable should be removed, and then fasten the new product in the handle and in the groove of the drum. After that, the cable should be wound around the roller, and finally assemble the body.

It’s important to know! Before fixing the cable in the handle, you should pass it through the corresponding hole in the starter cover.

Replacing the flywheel dogs

If it is necessary to replace the flywheel dogs or responses, then this is also not difficult to do. To do this, you will need to dismantle the flywheel, and then remove the pawls. Install new dogs only those that were originally (plastic or metal). This is very important, since replacing plastic pawls with metal ones will lead to accelerated wear of the flywheel. Details of replacing the chainsaw starter dogs are discussed in the video below.

It is important to note that you do not need to have special skills or experience to repair a chainsaw starter. All work can be done independently if you take the repair process with full responsibility. Timely maintenance of the chainsaw will allow you to avoid the occurrence of breakdowns when working in the field.

The starter is one of the most important mechanisms in any modern chainsaw. It depends on him to start the engine of the tool in any weather conditions. The chainsaw starter stands out for its simple design, it is easy to maintain and repair it yourself. However, in order to fix the breakdown, you must first find its cause. To do this, most often it is required to completely disassemble the standard mechanism.

How to wind a spring on a chainsaw starter

The chainsaw is an indispensable tool in the construction and procurement of firewood. Correct use with moderate work ensures long tool life without breakage. However, troubles can arise completely unexpectedly and a serviceable chainsaw loses its performance, and the malfunction can be completely trifling.

Typical breakdowns and repairs of the chainsaw starter

The appearance of various malfunctions of the starter leads to the inability to start the chainsaw. The most common starter breakdowns include:

- The starter pulley is completely burst or cracked;

- The spring has burst;

- Starter rope broke.

To fix each of these faults with your own hands, you will need certain tools. You must have a set of screwdrivers and a spare cable with you. It is necessary to remove and inspect the starter for the chainsaw in the following order:

- To find the cause of the breakdown, the starter will need to be removed from the chainsaw. To do this, unscrew the screws with a screwdriver, with which the protective cover with the starter attached to it is held;

- After removing the cover, you must carefully unscrew the screw by means of which the starter is attached to the protective cover;

- Then you need to try to smoothly start the starter. for this, remove the spring and clamps from it;

- Further, a coil with a cable is removed from the starter for inspection.

As a result of inspection, you can find a number of typical malfunctions. These include:

- Various damage to the pulley in the form of ruptures or cracks, mainly in the rear of the part. they interfere with the normal operation of the entire starter;

- Damage to the starter spring of the lightweight start. in such cases, not only the spring itself can be faulty, but also the place of its fixation. this is the most vulnerable part of the spring;

- Damaged starter flywheel dog.

In any case, any defective part must be completely replaced with a new part.

Chainsaw starter: device, breakdowns and DIY repairs

In the design of the chainsaw, the starter is responsible for the proper starting of the engine of the tool. Over time, owners of chainsaws are faced with the need to repair this important unit. And, the sooner it is possible to eliminate the malfunction, the less other important parts and mechanisms of the tool will succumb to wear.

The device and principle of operation of the chainsaw starter

Most of the well-known chainsaw manufacturers equip their products with starters that work on almost the same principle. Its essence is as follows: in the groove of the saw body there is a handle through which the cord is passed. When the handle is suddenly lifted, the cord is pulled out, which engages the drum, which is in the ratchet mechanism. This drives the spitz drum, which is located on the shaft. During this, the crankshaft makes a couple of revolutions, which leads to compression of the fuel mixture, which at this moment is located between the cylinder head and the piston. On the contrary, when the handle is lowered, the ratchet and the spokes lose their contact, which leads to a stop of the shaft.

With an increase in the power of the chainsaw, the amount of the fuel mixture increases, which should ignite when the chainsaw is started. In such a case, the number of jerks of the starter cord must be increased to start the engine. To speed up the return of the drum mechanism, manufacturers use a special steel starter return spring, which has excellent elasticity. Leading brands are using other methods to make it easier to start a chainsaw:

- Pre-enrichment of the fuel mixture using a separate flap;

- Installation of an automatic decompression valve, which reduces the pressure inside the cylinder of the chainsaw;

- Installing a primer designed to pump fuel before starting the engine.

The use of one of these technologies significantly facilitates starting and extends the life of the starter, which is especially noticeable at low temperatures.

How to replace a chainsaw starter spring?

In order to replace the old spring in the disassembled starter, you must proceed in the following order:

- Before installing the chainsaw starter spring, you will need to remove the mechanism clip. this should be done very carefully so as not to break the part;

- Then you need to look inside the clip. in it you will see a spring wrapped around a C-shaped element. To remove the spring, fix its upper part with your finger and pull the starter handle slightly to the side;

- After removing the old spring, you need to wind up a new part. At the same time, try to avoid kinking and twisting of the new spring element;

- To collect the chainsaw starter spring, you will need to act as carefully as possible, otherwise one wrong movement can lead to unwinding of the part;

- After you have managed to fully insert the spring into the starter, you must carefully fix the clip.

Chainsaw starter. Learning to self-repair

Any chainsaw requires a starter to quickly start. With accelerated scrolling of the crankshaft of the tool, the fuel-air mixture supplied to the engine is compressed and subsequently ignited. Therefore, the normal operation of the starter for the chainsaw determines the performance of the entire mechanism.

Chainsaw starter device

The principle of operation of a starter for a chainsaw is as follows. A handle is installed in the groove of the body, through which a cable is passed. If the handle is lifted sharply, the cable is pulled out and engages the drum of the ratchet mechanism, which transfers the movement to the drum with splines provided on the shaft. In this case, the crankshaft makes several revolutions, and the working mixture in the space between the piston and the cylinder head is compressed. Accordingly, when the handle is lowered, the contact between the ratchet and the splines is lost, and the shaft stops.

With an increase in engine volume, the required amount of the fuel-air mixture required for its subsequent ignition also increases, so the number of jerks for the starting cable for high-power saws increases. Therefore, in order to accelerate the return of the drum, unwanted return springs are used, made of steels with high elastic properties.

Chainsaw Repair. Replacing the Starter Recoil Spring (Poulan Part # 545008013)

Facilitation of starting the chainsaw is implemented in the following ways:

- By preliminary enrichment of the working mixture, for which there is a special damper in the carburetor design.

- Installation of an automatic decompression valve, which reduces the working pressure in the cylinder of the chainsaw.

- Installing an additional spring, which, during the movement of the cable, facilitates the unwinding of the crankshaft.

- The presence in the design of some chainsaws (for example, Partner S series, Maxcut, etc.) a primer. a pump that provides preliminary fuel pumping.

Spring repair

If the material of the starter spring is found to be of poor quality, the spring will burst (usually at the point of its attachment to the drum, where it forms a loop). In this case, it is not worth replacing the spring. Thoroughly clean its surface from dirt and traces of grease, gently grind the place of destruction, and then release the spring at 600 650 ° C (the steel of the spring should acquire a crimson color). It is necessary to cool the spring slowly, and at 100 150 ° C it is already possible to gently wrap its end in the shape of a restrictive protrusion on the inner surface of the drum (steel will acquire the necessary plasticity) and insert it into place. The elastic properties of the spring will not change.

Chainsaw starter repair

With frequent starts of the chainsaw, some parts of the starter are constantly subjected to dynamic loads. As a result, the cable may burst, several ratchet teeth may crumble, and the shaft will turn at a much lower speed. Therefore, the revision and even repair of the starter are operations that are sometimes carried out several times per season.

Replacing the cord

When pulling it out, there is a constant friction of the cable against the starter housing. To replace, disassemble the body of the unit, and carefully raise the ratchet drum so as to prevent the return spring from jumping off its seats. It is better to do this work together: the assistant fixes the spring while the cable is being replaced. After fixing the cable in the handle and in the grooves of the drum, the cable is wound around the roller, and the body is assembled.

How to put a spring on a chainsaw starter?

Fitting the starter spring into the correct groove is not easy, even for an experienced user. First, the spring should be twisted to the previous diameter and installed in the cavity of the drum hub. The outer end of the spring is fixed by the restrictive protrusion, and the outer end with a screwdriver should be positioned opposite the hole in the lock. The loop at the inner end of the spring is aligned with the hole with a screwdriver, after which the disc is lowered. Rotate the disc to check if the ratchet dog has come into place. Next, the ratchet itself is assembled.

After installing the spring, it is necessary to adjust its tension. To do this, a cable is inserted into the groove on the circumference, and a return spring is twisted around it. After removing the slack, it is better to wind the spring an additional few turns to ensure the required tension on the part.

Assembling the brushcutter starter

When servicing and repairing the starter, it is important to assemble it correctly. as if the assembly was carried out by the manufacturer. Any part that is incorrectly installed will prevent you from fully using the trimmer or brushcutter.

- After winding the spring, turn the coil over and place it so that the second spring hook falls back into place. To control the correct installation of the spring, there are technological windows on the coil itself.

- Install the starter pulley and make sure that one of the spring hooks fits into the groove located on the starter cover.

- Insert the spring and washers on the sides to prevent the spring from rubbing off the plastic compartment in which it is located. If the spring is broken, but the other is not the same, an additional washer is placed instead.

- Insert the antennae cup into the grooves of the coil.

- Install the coil in its place, tighten the bolt as far as it will go, but without fanaticism.

If you do not protect the compartment with washers from the main spring, where it moves when winding and unwinding the starter cord, the coil often gets stuck when you try to start the petrol trimmer or brushcutter. Loosening the coil bolt will result in its loss.

How to assemble a grass trimmer starter for brushcutters, watch the video.

Worst breakdown

There are times when the starter is still working, but a worn out cord can break, for example. The ratchet has not yet had time to work when the engine is started, and the remnants of the cord are immediately wound around the reel, the return spring loses its hooks, the grooves in the starter housing break. The result is the replacement of both the springs and the housing.

If the model of a lawn mower or grass trimmer has long been discontinued, it will be difficult to find exactly the same parts, and the starter is changed entirely.

How does the starter for a lawn mower or grass trimmer work??

The starter is a generally single and universal mechanism for petrol cutters, trim tabs, gasoline and diesel generator sets. It is not a problem to equip them even a car, motorcycle or scooter, if your vehicle has free space for its installation. It was not for nothing that many Soviet cars and trucks were equipped with a starter tool that vaguely resembles a tire bent twice.

The modern “handbrake” starts exactly from the cord. it is tied to the mechanism, and it is impossible to lose it.

The starter assembly has the following parts:

- hook ignition spring;

- cord wound on a reel;

- return spring;

- ratchet drive and main spring;

- mechanism housing protecting the ratchet;

- locking bolt.

Lawn mower starters: device and installation features

The recoil starter for a lawn mower or petrol grass trimmer is a mechanical unit that includes a pulley fitted to a ratchet. A rope is wound on the pulley in the initial position. At the start, it is pulled outward. The pulley is spring loaded. as soon as you let go of the end of the rope, it will reel back. A flat tape rolled into a ring is used as a spring. It resembles a spring in a large mechanical watch that is wound once a day. The starter itself is located more often at the rear than closer to the front end of the mower or grass trimmer. In order to correctly perform all manipulations with the starter for a lawn mower, you need to know the features of the device and installation.

How tight the spring is cocking?

It is possible to give the spring the necessary potential force necessary for a clear and fast winding of the cord, by determining the length of the cord in turns. To prevent the cord handle from drooping, add 1-2 more turns to the number of turns. So, if the cord has a length of 5 turns of the coil, then when charging the spring, turn the coil 6-7 full turns.

How to replace or replace the starter spring?

If everything is in order with the rope on the starter, suspicion falls on the reel itself. It is driven by a ribbon spring, coiled into a roll. To change the spring, certain steps must be taken.

- Remove the starter from the mower.

- Remove the starter coil.

- Unscrew the main bolt holding the pulley to the housing.

- Pull out the gripping tendrils and spring, the ribbon spring is almost fully extended or coiled into larger diameter rings.

- Hold it in advance.

- Check if the spring is intact (there may be rusty streaks, fractures, etc.). If the hooks at its ends are torn off, it will not be possible to bend new ones. high-carbon steel breaks when you try to bend it. Loose hooks are suitable for slight bending.

- Make sure the auxiliary (regular) spring and washers are in place. These parts protect the coil body from being punctured by the ends of the main spring. If the washers and spring are broken, and new ones are not available, do not tighten the coil bolt tightly, but watch it. it can unscrew and get lost.

- If the main (flat) spring is damaged, insert the same new one. Place the hook on the end of the spring in its place and bend it, inserting coil by coil into the space where it should be.

The rewinding of the spring takes a minute. Dexterity in this action is acquired quickly.

How to replace or replace the starter spring, see the following video.

How to assemble a new mower starter?

To assemble the starter, do the following manipulations.

- Pass one end of the cord through the opening at the beginning of the spool and tie it in a knot. The knot must not pass through the hole. Otherwise, you will disassemble the starter again.

- Wind the cord onto the spool itself.

- Install the spring into the starter housing, hook one end of it in the groove and wind it. For convenient winding, twist the body counterclockwise.

- Place the ratchet on the spring.

- Hook the return spring to the ratchet itself, attach it to the spool.

- Install the main spring and housing with the assembled ratchet, connect the parts of the starter together and tighten everything with the main bolt.

When you have finished assembling the starter, pass the free end of the cord through the hole in the housing for the reel. Re-pass the same end through the hole in the handle that the cord is pulling on. Tie a strong knot on the handle. Check the operation of the starter handbrake.