How to make a tiller lift

Product design

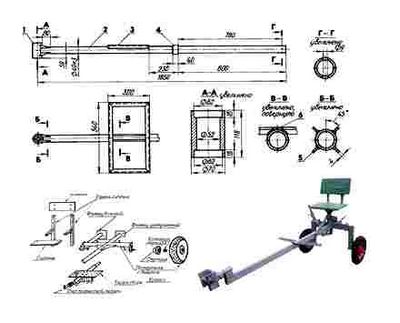

The adapter looks like a cart with a seat, made on a single axle frame. It is needed to universalize the device. Thanks to him, a semblance of a mini tractor can be made from the device. As a result, the labor intensity of tasks in agriculture is greatly reduced.

It should be noted that the adapter for the Neva tiller may differ from the adapter for the MTZ tiller, since the former are of 2 types: elongated and short.

In addition to the seat, the adapter has two couplings and a frame. One hitch provides the use of various devices: plows, diggers, harrows, and others. And the second is necessary for the contact of the adapter and the device.

- bodyless. used only for working with soil;

- bodywork. for freight transport and agricultural work.

Short-bed adapters can only be used for lightweight tillers, long-bed adapters can be used for heavy-duty.

Instructions

So, let’s figure out how to make an adapter. We make its base from a profile pipe (1.7 m. length), to which we weld the pipe (0.5 m. length) perpendicularly. The wheel fixing stands will be connected to the latter. The distance from the wheel axle to the top of the rack is 30 cm. The wheels can be taken from the garden carriage; bearings are put on its bushings. To do this, the bushings will have to be bored so that they fit the size.

Then we fix the braces, the length of which depends on the required angle. We weld them to the main pipe and to the wheel hubs. Next, we are welding the frame for an additional device. We attach the frame pipes located on the side to the wheel stands. To do this, we use bolts of a certain size that will withstand the expected loads.

On the rear end of the frame, we attach a channel (practice shows that it is better to use 0) using welding. The rear channel and the pipes located on the side are made 40 cm long.This allows you to get a square frame. A lever with 3 “knees” is also attached to it by welding, the length of which is 19, 30, and 50 cm. To increase the applied force, another 75 cm long is welded to the side of the lever.

Such a structure moves quite well on different soil. In its front part there is a do-it-yourself hitch assembly or purchase. You can also build a homemade snow plow for the adapter.

In addition to the main pipe, a metal “leg” must be welded to position the seat.

How to make an adapter to a tiller: instructions from a farmer

Tiller is an economical tractor option for small-volume jobs. Such a device is most often used to cultivate land in a country house or on a plot of a private house. It does not take up much space, it allows you to perform many procedures, for example, the whole range of measures for planting and harvesting potatoes. As a result, the unit enjoys great success among the villagers.

Transformation stages

- It is best to use a ready-made drawing of the kinematic diagram of the minitractor to ensure proper balance. To do this, you can use the data of the tiller Neva adapter with a steering wheel.

- The frame is created. For the trailer to turn, the structure must have a fork with a bushing.

- Body creation. A sheet of steel is used. Manufacturing of a structure involves the construction of boards with a height of more than 30 cm.

- The seat is mounted using bolts at a distance of about 80 cm from the beginning of the frame.

- Installation of equipment for work.

- Quality control.

- Painting the required parts.

Scheme

Let’s give a drawing of the adapter to the tiller in order to clearly understand its structure and general view. The standard device includes the following components and mechanisms:

- coupling elements;

- seat;

- wheelbase;

- frame.

A homemade adapter to the tiller must have the necessary level of reliability so that you can safely sit in it and perform all the necessary manipulations.

The constituent elements that will be required to create a structure with your own hands, as in

It is both pleasant and economical to create designs on your own.

Indeed, by creating an adapter, as in the photo, with your own hands, you can save a little money, especially if all the components are in stock, you do not need to buy them. And as a result of the work done, you can get great pleasure from both the process and the result in the form of a convenient, practical adapter for any of the commercially available tillers. This will greatly facilitate many of the processes that have to be done manually, working the land. Consequently, efficiency will increase significantly and more time will be saved.

How to make a do-it-yourself disc hiller for a tiller?

If you have a summer cottage, then you probably grow potatoes on it, the cultivation of which will be easier to produce with the help of special tools. Among them is the disc hiller for the tiller. With your own hands, this tool can be made with ease. A simple model of this type of hiller can be made from improvised tools.

Propeller-type hiller

Before starting work, you need to study the drawings of a disc hiller for a tiller, but if you do not intend to do the manufacturing work yourself, you can purchase a propeller tool. At the heart of his work. special propellers, under the influence of which the soil is first crushed, and then weeds are removed from it. And only then the loose soil is used for hilling.

Features of making hiller disks

When a disc hiller is made for a tiller with his own hands, the master should certainly consider the drawings. In addition, it must be remembered that the working blades must be prepared from the steel of the same density. In order to make a tool, you need to choose the type of discs. They will be steel sheets with a thickness of 2 mm. These components of the hiller should have lower edges that should be bent. The main condition is that the disks should be located symmetrically in relation to each other. Otherwise, the tool will lead to the side, which will complicate the work of the summer resident. When creating a structure, you can use plowshares that were borrowed from an old seeder. These elements, when a do-it-yourself disk hiller for a tiller is made, the drawings of which you can take from our article, must be mounted at an angle. In addition, you will need to maintain a step between the lower points, which should be equal to the width of the wheel track. This parameter is equivalent to the width between rows. The elements can be connected to each other using bolts; it is permissible to use a welding machine. The discs must be mated with each other using an adjustable adapter. In addition to discs, stands, screw lanyards, and a leash act as the main elements of the tool. The last of them must be done in the form of the letter T.

The do-it-yourself disk hiller for the tiller should be made using lanyards, which are needed in order to adjust the axis of rotation of the disks. This tool should be fixed to the tiller by means of a beam that has wings. During the manufacture and installation of parts, the specified size must be carefully observed.

Making a lister hiller

The simplest option for making a hiller is to make a model that has a fixed working width. This design is represented by wings, which are connected and somewhat spread apart, as well as fixed to each other. There should be 2 such elements in the equipment. Due to the fact that the wings remain stationary, it will be impossible to adjust the working width. Therefore, the width between the beds will need to be adjusted to the tool, and not vice versa. A do-it-yourself disk hiller for a tiller, as a rule, is made according to the principle of factory equipment, the gripping width of the tool is 30 cm, which is not very convenient, because the width between the dispersion of potatoes assumes a parameter equal to 60 centimeters. The presence of thin racks acts as a feature of lister hillers. This allows you to withstand the overload of the cultivator when carrying out the destruction of the tool into the ground.

Features of self-made disc hiller

Before making a do-it-yourself disk hiller for a tiller, you will need to prepare the necessary materials. You will need to use a template made of steel. The thickness of the latter should be equal to 2 millimeters. From the canvas, you will need to cut out the halves of the tool. These workpieces must be bent until they coincide with the radius, only then can you start welding. Weld seams should be machined with an angle grinder. If necessary, the elements need to be welded, and then cleaned well. Ultimately, you should get an even layer of metal, the surface of which should be perfect.

Features of the hiller with variable working width

If you are thinking about how to make disc tiller for a tiller, you should know that such tools are most convenient if they have a variable working width. This is due to the fact that they have an adjusting mechanism, with its help you can adjust the position of the wings. This allows for a variable width between rows. Such hillers are used in tandem with tillers, the motor of which demonstrates a power of up to 4 liters. from. and more.

Among the disadvantages of such tools, one can single out significant energy intensity. The main advantage of disc hillers is the successful combination of the tool with the tiller. In the process of using such a tool, you will achieve the greatest efficiency.

Tool manufacturing options

A do-it-yourself disc hiller for a tiller can be made using one of two technologies. One of them involves the use of a variable, the other is a fixed wing width. In the first method, the distance between the discs can be changed by the method of rearranging the stands.

A do-it-yourself disc hiller for a tiller can be made in such a way that it is possible to facilitate work with the tool. For this, it is necessary to provide for the presence of sleeve bearings. Once the bearings are installed, you can improve the reliability of the tool. In this case, you should not use slip bushings.

Dimensions and features of the manufacture of hedgehogs

a tiller with an attachment for growing potatoes will save time and effort when caring for this crop. Weeding hedgehogs are a functional attachment that allows you to quickly and efficiently defeat weeds. In the process of weeding, the plants are not simply cut, but uprooted. The land around the plant is well loosened and huddled. Thanks to this, the plant not only gets rid of weeds, but also receives sufficient water and oxygen.

Based on diagrams and drawings, you can make them yourself.

Components for hedgehogs:

- 3 discs made of metal or a ring;

- a small piece of pipe with a diameter of 30 mm;

- steel dowel rods.

It is preferable to use rings instead of discs, which will lighten the whole structure. The sizes of rings for making tiller’s hedgehogs are different. The most common are 240x170x100 mm or 300x200x100 mm. The rings are attached to the pipe through jumpers. The connection must be made at an angle of 45 degrees with a distance between the elements no more than 15-18 cm.

The spikes, cut from a steel rod 10-15 cm long, are welded onto the rings and the axle itself. Depending on the size, they are attached to a large ring in the amount of 15 pieces, to a small one. 5. Also, several pieces can be welded onto the axle.

To facilitate the work with the structure, the hedgehog tiller is equipped with additional wheels.

How to make attachments for a tiller with your own hands?

- How to make a flat cutter with your own hands?

- Dimensions and features of the manufacture of hedgehogs

- We make a snowblower bucket with our own hands

- How to design a trencher?

- Manufacturing of other suspended structures

In order to increase the capabilities of the tiller, it is enough to equip it with various attachments. For all models, manufacturers have developed numerous add-ons, the use of which makes it easier to work on the ground.

On sale you can find plows and seeders, hillers, furrow diggers, sledges. The choice, of course, is large, but many cannot afford the cost of such equipment. But it is quite possible to make it on your own from cheaper or used materials.

How to design a trencher?

A homemade trencher is a hinged attachment to the tiller, which allows you to quickly and effortlessly dig trenches and holes. It is a kind of compact excavator that is maneuverable and economical. Moves on a wheeled or tracked chassis.

The digger attachment allows you to dig trenches and holes even in frozen ground. The walls of the trenches are flat, without shedding. The excavated soil is light and crumbly and can be used for backfilling.

Making a Sailboat tiller.

Two cutters are fixed on the front suspension, on the rear. a shovel for extracting soil from the trench. It is imperative to attach safety guards to the cutting discs and the chain drive. By the same principle, a drill bit is made from a metal rod and plates.

We make a snowblower bucket with our own hands

the tiller is useful on the farm not only in summer, but also in winter. It is often equipped like a snow blower. It is enough to make a bucket for the tiller, and the iron assistant will do the hard work.

A snow shovel is usually made from a 200 liter iron barrel. You will also need metal strips, a square pipe, rubber and steel plates and fasteners. bolts, nuts. From tools. pliers or pliers, drill and drill bits for metal, wrenches, grinder, welding machine.

an angle grinder at the barrel, the side parts are cut. Then the workpiece is cut into three pieces. Two of them are welded along the contour. The remaining third of the barrel needs to be divided into metal strips, which will be the bucket knives. Three 6mm diameter holes are drilled into them for attachment to the edge of the bucket. Instead of a barrel, you can use a metal sheet, which will need to be bent by heating.

A strip of metal is welded to the bottom of the bucket to make it heavier. The metal strip is completely covered with rubber to prevent wear. The bucket is then attached to the tiller. To protect against corrosion, a homemade bucket is primed and painted.

You can turn a wheeled tiller into a snowmobile using a trailer and winter wheels. With the help of the channel, the trailer is fixed to the frame. Used truck cameras are used instead of expensive wheels. On each wheel, the deflated chamber is secured with chains and inflated again. Equipping a snowmobile machine is quite simple and homemade sleds.

How to make a flat cutter with your own hands?

A practical addition to the tiller is the flat cutter. This is an irreplaceable assistant who creates beds, weeds and spuds plantings, levels, falls asleep, loosens the ground. The possibilities of such a nozzle are almost endless.

If you place the blades of the plane cutter on the left and lead in the same plane with the soil, then you can weed or loosen the ground. Raising the appliance slightly, the blades turned to the left will mow tall weeds. If the blades look down, then it is easy to create beds with them.

A flat cutter will again help to form grooves for planting and fill in the seeds. This is the function of the burier.

You can use the Fokin plane cutter as a hitch for a tiller. He has the necessary holes for hanging on the structure. If a flat cutter of a different size is required, then you can make it yourself. Drawings and a small metal workpiece will help with this.

The metal must be of sufficient thickness and strength so that in the future it can function as a blade. The sheet is heated with a blowtorch and bent according to the pattern. When the plane cutter is in shape, it is cooled with water. In order for this workpiece to become an attachment, it is necessary to make holes for fasteners and sharpen the workpiece with an angle grinder.

A sheet of metal can be replaced with a piece of pipe, to which pieces of metal are attached like blades. They need to be sharpened.

Manufacturing of other suspended structures

So, to cultivate the land, a plow is needed that can overcome virgin soil overgrown with grass, wet or stale soil. To make it, you need a steel plate about 5 mm thick. Using the rollers, the plate is bent into a cylinder. Edges sharpen angle grinder.

The resulting home-made plow is hung on the tiller’s stand through the hitch.

By the same principle, it is easy to make a furrow-forming attachment. It is good if there are stands from the cultivator. They can be attached to a corner or made two racks from scrap materials. For this, plates are cut from a metal sheet with a thickness of 1.5-2 mm. The size of the plates should correspond to the depth and width of the furrow. They are fastened with bolts to the struts of the structure. You can use such a nozzle for instillation. One has only to give the plates the required shape. They should be in the form of a disc or circle, located at a certain angle. From above, such plates are located closer than below. Due to this, the discs, while rotating, open the cavities outward.

The cranberry tiller attachment contains a self-propelled crawler platform. The intake is fixed on the swing frame of the platform. It is made in the form of a box with bent parallel teeth. Moving, the device with the help of the fan pulls the berries into the box. The fan is powered by the engine. Screw-shaped spirals are installed in the box.

Plucked cranberries are heavier than garbage, so they fall to the bottom of the container. Leaves, small specks that fall along with the cranberries, along with the air flow from the fan, are removed through the hole.

The tiller brush is used for cleaning the area not only from leaves, but also from shallow snow. Simplicity, efficiency and versatility of use are the obvious advantages of this hinged element. A brush shaft is vertically attached to the tiller. A ring and discs with brushes are alternately put on it. The diameter of the rings is 350 mm. The width of the grip of such a brush is usually made no more than one meter. This allows the tiller to remain manoeuvrable and cover a fairly large surface area for cleaning.

The length of the bristles is 40-50 cm, otherwise it will soon begin to wrinkle and wrinkle. It will not be possible to restore the properties of the bristles, just attach new discs. The speed of the tiller with the attached brush fluctuates in the range of 2-5 km / h, depending on the engine power of the unit.

To learn how to make a plow to a tiller with your own hands, see the next video.

Model with rivets

Folding this type of lift with your own hands (the drawing is shown below) is quite difficult. First of all, it is necessary to prepare a thicknessing machine for the rivets. Next, it is important to process the base for the lifting mechanism. For this, two plates must be used. Cast iron is rarely used in this case. In turn, steel surfaces are less susceptible to corrosion, and this should be taken into account. On the bottom beam, rivets are made at intervals of 23 cm.

Further, in order to assemble the lift with your own hands, it remains only to fix the hydraulic mechanism. In this case, pneumatic modifications are rarely used. The piston in this situation should be at least 4.5 cm in diameter. Shoes are most often used of steel type. A lever is installed to adjust the lifting mechanism. For greater stabilization of the base, the supports are welded. Directly the platform is made with rubber pads.

Model with two-foot shoe

To make this type of scissor lift with your own hands, you first need to tackle the lower beam. To this end, many experts recommend preparing a clamp in advance. With its help, it will be possible to hold the center pin. However, first of all, it is important to fix the frame. To do this, you will have to use a welding inverter.

Further, in order to assemble the lift with your own hands, it is important to choose a high-quality hydraulic device for lifting the beam. After installing it, the handle is mounted. A single-channel gearbox is suitable for these purposes. The lift stand can be made from an aluminum plate. Mechanism supports are installed last. Before doing this, it is important to check the strength of the clamp. In order to weld the supports, you will have to use a welding inverter.

Lift with rear L-shaped beam

And with an L-shaped rear beam, how to make a lift with your own hands? In order to qualitatively assemble a model of this type, first of all, the base is harvested. For this, the plates are selected of steel type. Their minimum thickness must be 2.2 mm. Further, to assemble the lift with your own hands, you need to attach the side supports. For this purpose, it is not necessary to use a clamp.

The next step is directly welded the beam. To make it yourself, you will need three equal-sized sheets of metal. Dina their minimum must be 120 mm. After welding them, the upper beam is fixed. In this case, the hydraulic mechanism is more expedient to use a small-sized one. Thus, the gearbox can be placed next to it.

Device with three-leg shoe

It is quite simple to assemble a car scissor lift with a shoe on three supports with your own hands. In this situation, the base is harvested U-shaped. After that, it will be possible to fix the pickup. For this purpose, many experts recommend using a clamp. The direct hydraulic mechanism can be mounted on screws. At the same time, it should not overlap the supports.

Further, to make a do-it-yourself car lift, you need to fix the gearbox. For this, a small plate is cut out of the steel sheet. It must be welded to the upper beam. In this case, the indent from the edge must be at least 2.2 cm. After that, the shoe is attached directly. The first support is installed at the hydraulic mechanism. At this time, the other two feet should be at the front edge of the model.

Steel bar modification

To make this type of lift to the garage with your own hands, the pipe should be selected with a diameter of about 4.5 cm.Then you need to prepare the basis for the device. Most often, it is set in a U-shaped form, but other modifications also have the right to exist. In this case, much depends on the dimensions of the hydraulic device. You should also consider the power of the pump, which is intended for lubrication. If we consider the simplest model with a steel rod, then it is better to choose the L-shaped base. Cast iron beams are perfect for her. To make a lift to the garage with your own hands, then you need to install the platform for traction directly. For this purpose, sheets are mainly used of steel type. However, the aluminum alloy is also quite strong. The rod itself should be installed in the middle of the lower beam.

For this purpose, a notch is made in this place. It is best to use a clamp to secure the top beam. After fastening the hydraulic device, the gearbox is installed. For this type of lifting mechanism, it needs a single channel. In this case, the rack must be installed under the supports. In this case, the pickup is welded last. In this case, it is necessary to calculate in advance the length of the lever so that it does not come into contact with the supports and the upper beam.

Model with a U-shaped rear beam

And with a U-shaped rear beam, how to make a lift with your own hands? Answering this question, it must be said that in this case it will be difficult to make a base. To do this, you will have to cut many long sheets of steel sheet. In this situation, experts recommend installing a cast iron shoe. In this case, the hydraulic mechanism must be located at the lower beam. Further, in order to assemble the lift with your own hands, you need to mount the gearbox.

To do this, you will have to use a clamp. The first support is welded only after the clamping nut has been secured. The beam should be cut on the machine. In this case, the distance between its corners must be at least 230 mm. Some modifications of this lifting mechanism involve the use of pumps. They are necessary in this case for the lubrication of the hydraulic mechanism. To install this part, it is important to weld an additional support at the rear beam. In this case, much depends on the dimensions of the piston pump.

Aluminum rod device

To make a do-it-yourself car lift with an aluminum rod, you need to pick up a pipe with a diameter of about 4.4 cm.After that, its upper part is carefully sharpened. This is necessary in order to weld a pickup to it. In this case, four supports must be prepared. The stabilization of the hydraulic device is increased due to the use of special clamping nuts. In some cases, caissons are installed in structures.

In models with pumps, they are quite popular. Supports are most often selected steel. The minimum thickness of the metal in this place should be 3.5 mm. Further, to make a do-it-yourself car lift, you need to install a gearbox. The mechanism must be controlled through a lever. The rod must be directly attached to the longitudinal platform. For this, the beam is harvested rigid.

Plasterboard lifts

It is quite problematic to assemble a drywall lift with pads with your own hands. In this case, you cannot do without a clamp. First of all, it is important to weld the base for the device. To do this, you will have to use the machine. In this case, the pads are easiest to make from steel plates. In this case, the supports for them must be selected quite strong, the minimum metal thickness should be 2.2 mm. At the same time, there are a wide variety of pickups. The lower beam in this situation can be made from steel sheets.

For this, they are cut with a width of about 120 mm. Caissons in these devices are rarely used. It should also be noted that the hydraulic mechanisms are suitable for different capacities. In this case, a lot depends on the area of the lower beam. To stabilize the device during operation, many experts recommend welding rigid supports in the lower beam. It is necessary to install the rack on the lifting device only after fixing the hydraulic device. In this situation, the pads must be mounted on the upper part of the shoe. A common nut is used as a clamping device. To adjust the tension of the mechanism, as a rule, a conventional lever is used.

How to make a trailer for a tiller with your own hands: instructions

What can you do with your own hands from scrap materials? Almost everything! Starting with the simplest furniture, ending with movable vehicles. And today we will consider one of the ways through which you can make a trailer for a tiller with your own hands.

Getting Started

So, we have prepared tools, a drawing and necessarily a welding machine, because without it it is simply impossible to make a homemade trailer to the tiller, because such a structure will not pass for a long time on self-tapping screws. First you need to make a frame. This is also the basis for a trailer, therefore it is necessary to measure and make calculations with high accuracy. Errors in sawing and joining channels are excluded. A do-it-yourself trailer for a tiller can be made from rectangular pipes measuring 60 by 30 millimeters, which will serve as the basis for the entire structure. In addition, it is necessary to prepare 2 steel squares measuring 25 by 25 millimeters, which will act as a traverse. All this must be welded together and secured for structural reliability with 5-6 crossbars. In this case, the traverse and cross members should form small outlets relative to the side members.

We weld a couple of longitudinal pipes on the sides to the front of these edges, on which the racks will be installed further. The upper straps must be welded to the latter. As a material, you can use all the same 25 mm pipe with a cross section.

Pay special attention to the sides as well. In addition to the rear one, it is advisable to make 2 side folding ones, which will greatly facilitate the loading and unloading of various building materials and make the trailer more versatile, since you will have the opportunity to transport oversized cargo. The metal of the sides should have a thickness of no more than 0.8-10 millimeters.

What needs to be done first?

At the first stage, it is necessary to develop a drawing, present the future view and at least the approximate dimensions of the trailer. After that, you need to calculate how many meters of rolled metal you need to purchase for this structure, including the channel. They will serve as a frame for your hitch. So you will not only save money on purchasing, possibly, extra corners and screws, but you will also be sure of the correctness of your actions. Because anything can come out at random, just not a trailer.

DIY trailer for a tiller: chassis

This is a particularly important aspect when designing a homemade device. Here, as wheels and springs, you can use parts from any domestic car, for example, “Zhiguli” or “Moskvich”. These units are connected to the beam by a welding machine, and the ends are connected to the spars. On the latter, by the way, it is necessary to install the axis of the earring and the bracket.

And the last thing to do. it’s a drawbar. At this stage, the question of how to make a trailer for a tiller with your own hands will be accompanied by welding a 60×30 mm pipe to the front ends of the side members. In this case, the ends of the beams must be docked and welded to the body of the towing coupling. This gives you a complete 2-beam drawbar.

Photos and descriptions of interesting options

DIYers have already come up with a considerable number of original trailer options. Perhaps one of the following will suit you as a sample.

The small tipper truck has small wheels, a simple frame design and no brakes. At the same time, making a tipping trailer is not difficult at all, you just need to provide pivoting loops and provide for fixing the body when driving.

A biaxial version is also possible. Such a trolley is suitable for the transportation of heavy and bulky cargo paired with a powerful tiller, while a swivel mechanism of the front axle is required and the braking system will clearly not be superfluous.

It is very wise to use a piece of construction from a heavy motorcycle. In this case, a soft suspension with springs and shock absorbers is provided. The wheels of the motorcycle are lightweight and adapt well to the load. The luxurious car seat increases the comfort of movement.

Seeing a wide bench, it is difficult to resist the words: “Give us a ride, Petrusha, on a tractor.” If two people are to use the tiller, of course, you should provide adequate seating.

If you have to transport hay, you should provide high sides. This requires nests along the perimeter of the boards.

Like a mining dump truck, not a tiller cart. However, the powerful water-cooled engine allows for the transport of a large amount of land.

This unprepossessing-looking option seemed the most practical. The loading platform is lowered, which makes loading easier and increases the stability of the trailer when driving. Suspension on springs and shock absorbers plus a car seat promise comfort to the driver of the motor vehicle. In general, if not a Mercedes, then a cool bike will definitely pull.

Probably, such a car is not even a “Zaporozhets” ?! He has a trunk at least in front, but here, where to put the load? The owner will have to sit on a pile of sand.

We decide on the dimensions and prepare homemade drawings

The tiller trolley is a serious business, so you should start with the drawings. It is clear that each home-builder chooses his own solutions, however, the sizes of existing products will clearly help.

These drawings can be used to assemble a medium sized rigid suspension trailer. In this case, a body made of boards is assumed.

This drawing will help you make the frame of the trailer shown above. Usually, for these purposes, a profile pipe with a section of 25×25 mm or 20×40 mm is used.

This diagram illustrates the parameters of a hoist trailer. The telescopic stop can be easily made from two pipes of different diameters inserted into each other. A protrusion is provided on the frame, which fixes the front part of the body from lateral movements during movement. A stop under the drawbar provides horizontal fixation of the trailer.

This drawing will help you fabricate a simple flat loading dock structure. A light trailer can be made from a profile pipe with a section of 20×20 mm or a corner of 45×45 mm.

It is convenient to use a suspension for a trailer from a motor scooter “Ant” or to make the same one on your own. Two independent levers on silent blocks plus shock absorbers with springs will provide a high smoothness of the ride.

Another drawing of a trailer with soft suspension. In this case, it is assumed the use of a torsion bar suspension from a motorized carriage or “Zaporozhets”. Note that no matter what design you have chosen, at least the simplest sketch of the frame with dimensions must be prepared. This will help avoid mistakes, waste of material and wasted time.

Composition, structure and characteristics of trolley trolley

When planning the manufacture of a trailed cart with your own hands, it is important to figure out what it is. The composition and design of assemblies and parts differ markedly depending on the need for the transportation of goods and the engine power of the unit.

In the maximum configuration, the tiller trolley consists of the following elements:

- frames;

- undercarriage;

- body;

- coupling device;

- driver’s seat;

- brake system;

- parking stop;

- lifting mechanism.

Making a simple do-it-yourself trailer for a tiller

It is difficult to completely repeat the already existing design of the product, since each of us has our own set of materials and components, homemade experience and trailer operating conditions. The main structural elements are the suspension and the frame, so we will start with their consideration.

Often, the rear Zhiguli beam is used as the basis for the suspension together with hubs from front-wheel drive cars. The solution is simple and reliable.

The beam is welded to the trailer frame in an upright position. At the same time, the loading platform is quite high. The beam dictates the size of the trailer, so it turns out to be heavy and solid in size. For a weak air-powered tiller, this option is useless.

To reduce the dimensions of the suspension, you can cut out the central part of the beam, and instead of it weld a pipe with a section of 50×50 mm of the required length as an axis to the hubs. The adult version of the stroller presented in the photo can easily be rearranged by the hands. In more detail, the manufacturing process of this structure can be evaluated using the following video.

In theory, a rear beam from any passenger car could be used. At the same time, it is more convenient to use the rear suspension of a front-wheel drive car of possibly smaller mass and dimensions. The suspension of the car “Oka” is well suited in terms of load capacity.

The photo shows two options for trailers with a rear axle from the classic VAZ as an axle. The gearbox should be removed, and its place should be closed with a metal plate on bolts. The axle shafts must be pulled out, cut to 200 mm and reinserted. Practice has shown that they successfully adhere to bearings and do not go out. The bridge is welded to the frame with two jibs on each side.

A trailer with a soft suspension is noticeably more comfortable, although more difficult. The load does not bounce in the cart on every bump, and the driver’s “fifth point” does not experience unnecessary overload. Probably, installing springs and springs at the same time is a clear overkill. At the same time, it is not so difficult to make levers on silent blocks and install springs.

The cart for the transportation of bulk materials must be folding. In this example, the frame is made of a 50×50 mm corner. Hinges are welded to its rear and body. The axle of the bogie is positioned exactly in the center of gravity of the load. To unload, the trailer must be placed on a stand, disconnected from the trailer, and then tilted, lifting the drawbar up. Be careful to avoid sudden movement of the drawbar.

How to make a trolley for a tiller with your own hands: photos, drawings and dimensions of a homemade trailer

a tiller without a cart is almost “like a song without a button accordion”: you can cultivate, but you won’t be able to transport the load. Buying a factory trailer is expensive, but making it yourself is quite realistic. This will require a welding machine and experience with metal.

Brakes, hitch, hubs and other components

When assembling a trailer for a tiller with your own hands, you will inevitably have to make a decision on the design of the brake system, hitch, parking stop and other things. We will evaluate possible solutions and choose suitable.

For heavy trolleys, a parking brake is essential. It will also fit from any passenger car and must be fixed to the frame next to the driver. If there are standard mechanical brake drives in the rear suspension, it remains to connect them to the handbrake lever with a cable of the required length. The hydraulic and mechanical brakes must be thoroughly tested before loading the trailer.

The hitch is another important trailer assembly. In the simplest case, a pipe is welded to the drawbar, in which a hole is drilled for the finger. For motorized towing vehicles with an air-cooled engine, its diameter is usually 16 mm, with water-cooled ones. 20 mm. In this example, the belay is very correctly arranged in the form of a chain, which is attached by the pin in the side hole of the hitch.

Often, a cardan is used as a pivoting element of the hitch. In this case, the side elements of the cross must be welded so that the trolley drawbar does not sag.

When using a 4-wheeled trailer, it is possible to use a factory vehicle hitch. In this case, you will need an adapter with a ball attached to the tiller.

Let’s consider several possible options for adapters for connecting a trailer. The first is the same ball we mentioned and it works with a 4 wheel trailer. The other two are a bushing welded to a rod that can rotate in the tube. The sleeve is inserted into the tiller hitch and secured with a pin. The tube is welded to the drawbar of the trailer. Thus, the trolley has the ability to turn in both directions when driving, as well as freely tilt on uneven roads. Sleeve height is 60-70 mm (depending on the tiller version).

Glass handling with Tiller®-liftmobile lifting equipment, www.tiller.eu

When parked, the cart may require a support. Spring design resembles a bicycle stop and allows you to lock the bar in two positions.

Reliable tailgate locks can be made from strip, rod and pipe. Angle grinder and welding are indispensable here.

On a small trailer, you can weld on conventional latches. In this case, the side walls should not tilt, otherwise the connection will spontaneously fall apart.

If the sides are supposed to be extended, it is necessary to provide for the eyes for the vertical posts. It is convenient to make them from a 40×60 mm profile pipe.

Sometimes it is enough to weld small lugs on the bottom of the body. Through them, you can tie an awning or load in a trailer.

The hinges for the tailgate can be welded independently from a bar and a tube. However, it is easier to weld regular door hinges.

It is convenient to use self-tapping screws with a drill to fasten the sheathing from corrugated board. Ordinary with a press washer or roofing with a seal will do.

We have already seen how a car seat or an office chair is used as a seat. A simple bench for sitting can be made with your own hands from a piece of chipboard, foam rubber and leatherette. The cover is attached to the base with a staple gun.

In this article, I tried to collect the most useful information for those who decided to make a trailer for a tiller on their own. A detailed story about the features of homemade trailers is offered by their owners in the following videos.