How to tuck the line into the trimmer

How to replace line in any trimmer

Technological progress provides us with a lot of opportunities to get rid of manual labor. This includes, among other things, mowing grass, which required a lot of physical energy when using a conventional scythe. In modern conditions, this process is much easier, because the applied technique minimizes all costs. Devices such as electric and petrol trimmers have firmly taken the place of irreplaceable assistants in gardening. Mowing grass with their help has become more fun than hard and exhausting work.

Structurally, the trimmer consists of an engine, a rod and a working body, which, depending on the vegetation being cut, is either a mowing head or a disc milling cutter. And if everything is more or less clear with the cutter, then sometimes questions arise with the nozzle. As a rule, they appear when the line ends.

How to properly wind the line on the reel? Understanding.

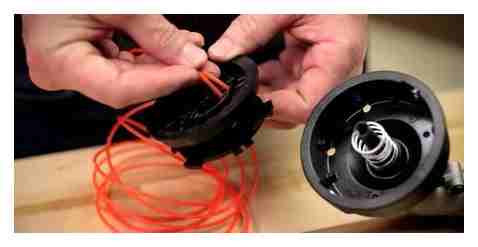

So, first unscrew the nozzle. This should be done by rotating the drum to the right. Here we have a drum with the remnants of an old fishing line in our hands. We open it. Most often, the lid is closed with latches that can be opened with a screwdriver, threading it through the holes and slightly pressing. Or you need to squeeze the latch and turn the cover in the direction of the arrow. In this case, the lid itself must be held, since reels with automatic line feed have a spring that, when straightened, can throw out all the inner parts of the drum. Gently pulling out the reel, remove the scraps of fishing line from it.

Now you need to take 5 meters of new line and fold it in half (to find the middle). In the middle part of the reel there is a notch (in some designs. a hole), for which we need to hook our fishing line. There is also an arrow on the spool showing the direction of winding. An important detail. if the reel has two compartments, then one half of the line should be wound in one direction, and the other in the other. When finishing winding, you need to leave 15-20 cm of line free. There are also two notches on the top ring of the coil, through which these free ends need to be passed. We dealt with the winding itself.

The last step in the line replacement process is to assemble the drum. First you need to install the spring and washers in their place. Then, holding the reel with one hand, with the other you need to thread the ends of the line into the corresponding holes on the sides of the nozzle. After that, install the coil in its place, tightening the line and being careful not to dislodge the spring. When all the internal elements of the nozzle take their places, you can close the drum with a lid. You just need to make some effort to ensure that the latches fall into place. Voila! The mowing head is ready for use!

We carry out the winding of the fishing line

Slowly completed disassembly of the spool-spool without losing its spare parts allows you to proceed to the main task. winding the fishing line into the reel. Technological features of the spool design and the number of working antennae determine the sequence of actions.

Preliminary preparation

First of all, to wind the fishing line, you need to remove the spool (bobbin, spool) from the trimmer. specific actions will depend on the complexity of the configuration and the type of the product itself:

- small electric trimmers with a working position of the engine and spools at the bottom, as a rule, have side buttons on both sides of the bobbin. When pressed at the same time, the upper part of the spool together with the inner content for winding the line is detached, while the lower part remains on the trimmer. It is advisable to disassemble the bobbin on a flat, smooth place so that the spring included in the structure does not jump out and is not lost;

- electric and gasoline trimmers with a curved bar without the possibility of installing a knife, as a rule, have spools with a special wing: in such designs, hold the spool in a stationary position with one hand, and rotate the locking reel on the bar with the wing nut counterclockwise with the other. After disconnecting the nut, the entire bobbin is removed.

- electric and gasoline trimmers with the ability to install a knife on a straight bar (for example, Stihl trimmers) have a hole under the reel. To keep the rod stationary, a screwdriver or other suitable object is inserted into this hole and, with slow rotation, such a mutual position is achieved when the screwdriver enters the hole and the bobbin is fixed. After that, the coil body is scrolled clockwise (with a left-hand thread) and removed from the trimmer.

For the second and third cases, the coils, depending on the design, are disassembled in different ways. In bobbins with a lamb, a lamb is unscrewed, in coils with latches, the latches are pressed and one part of the coil is released from the other. If the halves of the bobbin are connected by thread, then it is enough to turn them by hand in opposite directions until they are completely unscrewed.

Free as a Bird Fun Fold Card

Coil with one working tendril

The simplest option and uncomplicated sequence of actions:

- The dimensions of the reel and the length of the original factory winding determine the recommended length of the line for winding. 2. 5 m.

- One end of the line is inserted into the fixing technological hole located inside the spool.

- The fishing line is wound on the drum in the opposite direction of the spool rotation on the trimmer product. as a rule, on the inner side of the reel, an arrow indicates in which direction the winding is carried out.

- A small section of the line is left free to lead it out. it is fixed in a specialized groove on the inside of the bobbin, designed to hold the winding when assembling the bobbin into working condition.

- The left end of the line is passed through the hole in the outer part of the reel.

- The bobbin halves are assembled and put on the trimmer bar.

Coil with two working tendrils

In this type of spool, you should determine the number of grooves for winding the line, lying on the inside of the spool:

- one groove. both antennae are wound together in one groove;

- two grooves. each antenna is wound on an individual groove.

For both cases, a line with a length of 2-3 m is taken.In single-groove reels, the line is pulled into a through hole, its ends (antennae) are folded together and aligned, after which they are wound in the opposite direction of rotation of the bobbin on the rod side. inside the arrow usually indicates the correct direction of winding. If there are fixing grooves, the ends of the fishing line are threaded through them or held with the fingers of the free hand, they are threaded into the through hole of the outer half of the bobbin, the spool is closed and attached to the trimmer bar.

The difference between the line winding in two-groove spools is that initially a 2-5 m long line segment is folded in half (to determine the middle bend), and the bend loop is inserted into a special groove between the grooves. Both antennae of the fishing line are wound each along its own groove, fixing the antennae and assembling the coil is similar to the above option with one groove.

The first execution of this procedure, perhaps, will seem long and rather laborious, but with time and experience this task will be solved much faster and easier.

The video below will clearly show how to thread the line into the trimmer spool and wind it correctly. this operation is not difficult and with some patience it will certainly be crowned with success:

How do I load the line into the trimmer spool? Video instruction

The warranty production of the factory trimmer refueling will inevitably require line replacement. Having a very rough idea of how to thread the line into the trimmer reel on their own, beginners are reluctant to take up this business. However, with some skills, mastering this simple science does not present any difficulties, and the similar instruction presented below will make this process as easy as possible.

Automatic line winding on a spool

There is a type of reel in which the automatic mechanism winds on its own. from the user it is enough only to correctly fill the line. The fishing line is passed through a hole on the inner part of the body, its antennae without winding are passed through the hole on the outer body, the reel is assembled, and when the winding button is rotated, the fishing line inside is wound independently. In such a spool, it is impossible to make the winding wrong: the mechanism itself will determine the correct direction, since it can only turn in one direction.

Removing the spool from the trimmer

Now we will consider the issue of removing the hairpin from different types of trimmer:

- The bottom motor powered conveyor has two buttons on the sides. With one press of two buttons, you will need to detach one part of the gas station from the other. Simultaneously with the first half, remove the inner part, on which the core is wound.

Important! When doing the described manipulations, you need to be extremely careful so that the inner spring does not accidentally fly out and rub. This small detail is a very important “link” in helping to pull the line onto the roller.

- The body of an electric and gasoline conveyor with a bent metal rod should be wrapped around with one hand, and the other hand should be moved counterclockwise the electronic lamb. This small piece connects the reel to the trimmer bar. After removing the lamb, it is necessary to remove the entire coil, while holding the inner spring with your fingers.

- For an electric and ashless conveyor with a straight bar, you need to find a recess under the bobbin, insert, for example, a screwdriver into it, and slowly rotate it until the tool goes deeply and the roller is fully fixed. Next, turn the coil slowly clockwise (due to the left-hand thread) and remove it from the conveyor. Then you will need to disassemble the bobbin, assembled by snaps or twisted into a lamb. If you have a snap-on roller, then you need to push the latch on the sides to release the two parts of the part. After that, you should unscrew the lamb.

How to tuck line into the trimmer reel. lawn mowers?

What is a trimmer?

So let’s take a look at the trimmer varieties. They are of two types:

- Electrically powered.

- Gas tank fed.

Fishing line or knife. perform a cutting function in this device. In turn, the nylon thread can be as follows:

- Ordinary thread.

- With four or five faces.

- Intertwined (looks like a pigtail).

But a knife in a lawn mower can be:

- Two-bladed.

- Three-bladed.

- Four-bladed.

According to the material of manufacture, knives are divided into:

- Metallic.

- Plastic.

Line feed from a reel is:

- Manual type.

- Semi-automatic.

- With automatic feeding.

Important! The ranking of the most bought electric lawn mowers is as follows:

- ALKO.

- Bosch.

- Vitals.

- Iron angel.

- Daewoo

- Stark.

- Hyundai.

- Centaur.

- What is a trimmer?

- How to choose a fishing line?

- Removing the spool from the trimmer

- How to wind the line on the reel of a lawn mower?

Modern power tools help to facilitate human labor several times. So, for example, thanks to the trimmer, you do not have to mow the grass by hand, and the lawn will quickly and effortlessly become well-groomed and beautiful. For some people, a trimmer can help turn tough physical work into real fun. But what to do when the main cutting material runs out? Agree, not every person will immediately understand how to properly thread the line onto the reel of a lawn mower. For each type of coil, a corresponding nylon thread is needed and the replacement rules are completely different. Today we will consider all these issues in more detail.

How to choose a fishing line?

For each trimmer power, the developers accurately calculate the nylon thread diameter and the number of blades for the corresponding knife. Otherwise, the motor of the power tool will be severely overloaded, which will lead to its breakdown. Unknowingly, an overpayment for consumables will be provided to you. That is why the choice of line for your trimmer must be treated responsibly in order to keep costs to a minimum.

At the very beginning, you need to purchase the appropriate line. It is sold in skeins up to 120 meters long, and its diameter will be indicated in the detailed instructions for your trimmer.

- Most often, a 2 mm conductor is used for mowing grass with a trimmer. For mowing soft and young grass, it is enough to take a thin line, the diameter of which is 1.5–1.8 mm. But on more powerful lawn mowers you need to reel thicker fishing line.

- Do not forget to pay attention to the structure of the vein. For example, round cord is considered the most durable and copes well even with the toughest weeds. But the vein of a curly configuration is more suitable for young or twisted grass. A thread with notches along its entire length can only work with thin stems.

- The minimum length for one threading of nylon thread into the mower spool is 2-4 meters, depending on its diameter and the manufacturer’s recommendations. For example, if you wind too much line on the bobbin, then its movement will be difficult, and in the process of mowing the grass, you will notice new ends of excess material.

- It is advisable to buy only approved companies. which are listed in the recommendations of your mowing appliance. It must be made of high quality material and have good durability. it is good to “mow” the lawn and not wear out very quickly.

In order to increase the elasticity and strength of the cord, place the purchased thread in water for 30 minutes. Thanks to such actions, it will be difficult for you to break even the thinnest core.

How to wind the line on the reel of a lawn mower?

Steps for a roller with one tendril:

- To begin with, we unwind from 2 to 4 meters of nylon thread. Its length depends on the size of your coil.

- We find a hole on the inside of the roller. which fixes the vein. We insert one end of the nylon thread into it and begin to carefully wind it in the opposite direction to the rotation of the bobbin on the device. Sometimes an arrow is drawn on the inside of the spool indicating the direction of winding the line.

- After part of the core is already on the coil, we leave the rest of it (5-10 cm) free to expose it outside.

- We fix the tip of the core in a special groove (groove). You will find it on the inside of the coil. If you do not have such a groove holding the cord, then you need to hold the line with your finger.

- Now we take the outer part of the coil. we slowly pass a segment of the “hanging” core into the existing hole. The nylon thread is now wound on the bobbin.

- We put the roller on the conveyor.

Steps for a roller with two antennae:

- We look at the inside of the bobbin. determining the number of grooves for the core. The coil can have either one groove or two. Two antennae are wound along one hole at the same time. And a tendril is wound on a bobbin with two holes, which must travel along a separate groove. The roller with one groove has one through groove, along which the line slides.

- We rewind 4 meters of a new nylon thread. we pass it through a double hole so that the line segments from each part are the same.

- Now we wind the two ends of the core in a single direction, which should coincide with the direction of the pointer drawn inside the coil (arrows).

- We leave a small part of the core for stock. We fix its ends in the grooves.

- Slide the 2 ends of the cord into the groove on the outside of the roller.

- We collect all the components of the roller and attach it to the trimmer bar.

Important! If the conveyor has two grooves, then you need to fold the section of the core in half, and insert the loop obtained at the bend into the groove that is located between the two grooves. After that, both cuts of the line should be wound simultaneously, each in its own “way”. All further actions should be done in the same way as the above instructions.

Actions for a roller with a core threaded through a double-sided hole located on the inside:

- We thread the ends of the new nylon thread through the hole on the outside of the roller without winding.

- We collect the reel and press the button for further release of the core as it gradually wears out. When you rotate this button, the line itself winds inside the bobbin.

Important! If you do such winding often, then you can wind the nylon thread without disassembling the drum. To do this, you just need to combine the double-sided groove of the inner part with the grooves of the inner roller body, and then thread the same fishing line through them.

As you can see, it is quite possible to wind the core on the trimmer coil yourself. The winding technique depends on the type of your lawn mower and on the design of the reel itself. Below we offer you a video that will help you better understand the whole process and perform high-quality line refueling in your device.

How to tuck the line into the trimmer?

Any machine for mowing vegetation is necessarily equipped with a spool, which, in turn, may differ in different models with a filament feed system (automatic, semi-automatic and manual). It is from this parameter that it is worth starting from before deciding how to fill the line into the trimmer.

In order to tuck the line into the trimmer, you need to take at least 5 meters of material, which is then folded in half. The center of the cutting element must be inserted into a specially designated place, and then the cutting attachment must be wound using the visual cues on the spool indicating the direction. At the end of all the work, the lid, of course, will need to be tightened.

What is a trimmer?

This equipment is based on the following elements:

- a motor whose main function is to rotate the cutting head at the end of the rod;

- directly the head, consisting of a coil, on which either a fishing line or a knife can be wound;

- knives or fishing line rotating at high speed, which are the main cutting part of the device, how to load the fishing line into the trimmer will go a little further.

An electric device is inferior in its power to a gasoline one, so it is ideal for working on a standard plot of land that is adjacent to a house with source of electrical energy. The main positive aspects of such equipment are the absence of noise during operation, light weight, ease of use and, of course, environmental friendliness.

As for gasoline trimmers, such equipment, of course, is more mobile, so it can be safely transported from place to place and get rid of annoying vegetation in any area. There is no need to use electricity here, which has a positive effect on the functionality of such an apparatus. the cutting attachments can be changed, working with weeds of various types.

One of the most common attachments is the fishing line, so you should dwell on this element in more detail.

How do I fit the line into the trimmer? Operating tips

The trimmer is an excellent modern device designed for mowing unnecessary grass, and its main advantage is that this technique can be used in those places where an ordinary lawn mower will simply not be able to reach due to its massiveness. It is necessary to understand in more detail what trimmers are, and how to choose the best option for a particular suburban area.

Types of trimmer line

As a rule, line separation is based on different sample diameters, which can vary from 1.2 to 4 mm. The most commonly used material is a material with a thickness of 2 mm, but in no case should we forget that the choice should depend primarily on the trimmer model.

There is one main rule here: the more power the apparatus has, the thicker the line should be.

This element can also differ in the type of its section. So, it can be round (suitable for cutting plain grass) or square (for mowing soft green cover), sharp edges (tall grass) or be equipped with notches ideal for thin grass in diameter.

Do not forget that with the help of a fishing line it is allowed to mow only grass, and for other, coarser vegetation, it is imperative to use knives.

Next, you should take a closer look at the process of how to insert the line into the trimmer correctly. Indeed, it is with this procedure that many consumers often have difficulties.

Line adjustment

One of the main rules when replacing and adjusting equipment is that any manipulations with the mechanism should be carried out exclusively with the engine off and the device plug disconnected from the mains.

Perhaps these tips will tell you how to tuck the line into the trimmer as correctly as possible and, accordingly, give your site a neat and aesthetic appearance. All that is required is to correctly select the cutting material required by the type and, of course, to determine the category of the most used trimmer.

Preparing for replacement

We disassemble the trimmer spool

For clarity, the mowing head (spool) was removed from the lawn mower. To replace the fishing line, you do not need to remove it, everything is done locally. It doesn’t take long.

We disassemble the trimmer spool. it rests on the latches. Remove the cover by pressing on the latches. If you do not have enough effort to do this with your hands, then use a screwdriver.

The spool consists of the following:

- Spring case

- Cover with locking latches

- Button coil

The principle of operation is as follows. By pressing the button, the spool presses on the spring and comes out of the locking grooves in the spool cap. Holding in this state, the reel can be twisted, thereby adjusting the length of the line. When the button is released, the body spring returns the coil to its original fixed state.

Disassembled trimmer spool

On the bottom of the reel there are several holes for different diameters of the lines. They may differ from trimmer manufacturer. In some cases (like here) they are signed, in others they are not.

These holes are needed to fix the line when replacing it. After winding the fishing line on the bobbin, the ends of the latter are inserted into them. This is necessary so that the scaffold does not unwind when the coil is installed in the trimmer body. In other words, it makes it easier to change the line.

Holes for fixing the line

There are models without specifying the diameter of the consumable. Then, in order to find out what the maximum diameter of the scaffold can be used, it is tried on along the holes for removing the fishing line from the trimmer spool body (see figure below).

Fitting on the holes of the line output

The reel has two line sections separated by a baffle. They may not exist. They are needed only to delimit and facilitate the winding of the consumable.

Two sections for fishing line

First, they are determined with the required length of the loess. The latter is wound into one of the sections of the coil so that it does not go beyond its limits. In this case, 3 mm was wound, the length turned out to be about 2 meters. Those. for two sections you need a 4-meter segment. this is for the 1st method. For the second method, you need two segments of 2 meters each.

Determining the required line length

Now you need to figure out which way you need to wind it. To do this, many trimmer manufacturers apply special designations to the spools, such as in the figure below.

Special designation on the reel

If no such designations were found, then you need to pay attention to the spool body. There is necessarily an arrow that indicates the movement of the mowing head. The line is wound in the opposite direction.

Bobbin case designation

Line winding

Threading the line into the trimmer spool is a relatively simple procedure, provided you follow a specific procedure. When you need to determine how many meters of consumable is enough, wind it around the bobbin so that the skein does not exceed the diameter of the sides. Having decided on the length of the cord, follow the instructions below:

- Fold the consumable in half so that one end of the line is 10-15 cm longer than the other.

- Charging should be started from the center board, which divides the trimmer bobbin into 2 parts. Find the groove where the cord should be inserted. Bend the last in half.

- Determine in which direction you want to wind the line. To do this, take a closer look at the bobbin, which may contain an arrow or an inscription. She indicates the side of the winding. If there are no markings on the reel, then look at the arrow on the mowing head. wind in the opposite direction.

- The consumables should be washed carefully, turn to turn. Try to stick to the maximum thread tension.

- After completing the lining, secure the short end of the material first. To do this, insert it into a groove on the side of the coil that fits in diameter. The other end (longer), attach in the groove on the other side of the trimmer bobbin.

- After securing the fishing line, cut off the ends. Do not forget to leave allowances of about 10 cm.

- Place the loaded bobbin onto the mowing head of the device. To do this, you need to alternately insert and pull the thread into the outlet holes of the head, in order to then place the bobbin of the device into the skin.

- Using the required force, pull the cord out of the locking grooves and tighten the material. After completing this step, put on the cover and secure it with the latches.

Step-by-step winding of the line to the spool

You can also wind the cord on the trimmer in another way, in which two pieces of material are charged instead of one. The replacement is done like this:

- Bend one end of the cord into a crochet hook.

- There should be a hole at the bottom of the bobbin to hold the line in place. Insert the bent end of the thread there.

- Wind the cord material in the direction of the arrow to the desired level, which does not exceed the diameter of the trimmer spool.

- Do the same for the second bobbin compartment.

- The assembly of the device head is similar to the first method.

Coil with one working tendril

The simplest option and uncomplicated sequence of actions:

Changing the line in the trimmer: 2 easy ways

A trimmer is a necessary and useful tool for a summer cottage and a private house. Many people own and actively use it, but not everyone knows how to replace the line in the trimmer, especially at first.

In this manual, we’ll walk through the entire replacement process step by step. Looking ahead, there are two ways to line the trimmer spool. There is no fundamental difference. the difference lies in the fact that in the first case one line will be refueled, folded in half, and in the second there will be two such lines.

How to thread a trimmer reel video for beginners

How to wind line on a trimmer

You don’t need to have any special skills to reel in a gas or electric trimmer. To begin with, it is important to decide on a suitable consumable, and then choose the best method. There are two different ways to load the line into the spool of the device.

Coil with two working tendrils

In this type of spool, you should determine the number of grooves for winding the line, lying on the inside of the spool:

- one groove. both antennae are wound together in one groove;

- two grooves. each antenna is wound on an individual groove.

For both cases, a line with a length of 2-3 m is taken.In single-groove reels, the line is pulled into a through hole, its ends (antennae) are folded together and aligned, after which they are wound in the opposite direction of rotation of the bobbin on the rod side. inside the arrow usually indicates the correct direction of winding. If there are fixing grooves, the ends of the fishing line are threaded through them or held with the fingers of the free hand, they are threaded into the through hole of the outer half of the bobbin, the spool is closed and attached to the trimmer bar.

The difference between the line winding in two-groove spools is that initially a 2-5 m long line segment is folded in half (to determine the middle bend), and the bend loop is inserted into a special groove between the grooves. Both antennae of the fishing line are wound each along its own groove, fixing the antennae and assembling the coil is similar to the above option with one groove.

The first execution of this procedure, perhaps, will seem long and rather laborious, but with time and experience this task will be solved much faster and easier.

The video below will clearly show how to thread the line into the trimmer spool and wind it correctly. this operation is not difficult and with some patience it will certainly be crowned with success:

How to properly wind the line on the trimmer reel. Step-by-step guide VIDEO

How to wind the line onto the trimmer spool

How to choose a fishing line. length, diameter, restrictions

IMPORTANT TO REMEMBER! Do not use fishing line or metal cables for the trimmer. This replacement is ineffective and dangerous. The rope can injure not only the mower himself, but also those around him.

As for the length, you should rely on the estimated frequency of use of the trimmer. The more often, the more it costs to stock up expenses.

Information about the possible line diameter can be found on the body trimmer spools. Most likely, the range will be indicated there. The thickness varies from 1.2 to 4 mm. Choose the appropriate option, taking into account the characteristics of the cultivated area. The larger the diameter, the easier it is to mow tough grass.

Preparation. remove and disassemble the spool

On most electric and petrol trims, you will need to remove the spool to replace the line. The FUBAG tool lets you skip this step. To make the instruction universal, we will still consider it in detail:

Secure the shaft. Insert the locking element into the corresponding hole. It can be a thin screwdriver or a metal rod.

Unscrew the bobbin case. In our example. strictly clockwise.

Unscrew the cover according to the direction indicated on the body.

Remove the coil for winding.

The preparatory stage has been passed. You can proceed to winding the fishing line.

Winding Algorithm

Insert the resulting loop into the groove.

Lay the line in the direction indicated on the element body.

Insert the short end into the slot on the side of the spool.

Secure the long end in the opposite groove.

Place the spool of coiled line into the spool body.

Pull the line out of the locking grooves.

Put on the cover and fix.

Trim the ends of the line, leaving 10 to 15 centimeters.

The replacement of the line is completed and now all that remains is to screw the bobbin onto the trimmer and you can work.

ATTENTION! Typical line problems

No wonder they say: “Forewarned is forearmed“. Knowing about possible problems and the causes of their occurrence, you can prevent them in time. We recommend to remember or leave a memo.

Diagonal Fold Snowflake Spendor Card

| Problem | Cause | Decision |

| Line break | Stones, branches and solid objects in the grass | Avoid collision |

| Poor cord quality | Replace with a quality analogue | |

| Head outlet wear | Complete replacement of part required | |

| The line is unwound | The spring in the coil is weakened | Check spring and replace if damaged |

| The line is sticking | Poor line quality, due to which it can melt under the influence of temperature from the heating head | Reel in less line or replace with a better line |

For a better understanding of the mechanism of the process of changing the line in the spool with a video guide prepared by FUBAG specialists: