How to use a tachometer for a chainsaw

Chainsaw refueling instructions

Knowing the ratio of the preparation of the petrol-oil mixture, you can start refueling it. The refueling instruction is as follows:

- First you need to prepare the mixture. Having combined the two main components, you should mix them thoroughly.

- Place the tool on a clean and level surface. Before unscrewing the gas tank cap, it is necessary to clean or blow off sawdust, dust and dirt.

- The filler neck must point upwards

- Install a small watering can in the neck, then pour fuel

- Control the refueling process, as the volume of the tank is small, so it fills up quickly

- Do not fill up to the full maximum, since when the tank cap is closed, the remaining fuel will splash out.

- After the fuel is poured into the tank, immediately add chain lubricant.

- Fuel consumption and chain lubrication are approximately the same, therefore both tanks must be filled at the same time.

- After refueling, you can start starting the engine

It is better to start the engine not in the place where the refueling was carried out, but to move to a distance of 2-3 m. The tool is ready for work, and you can start to start it. How the chainsaw engine starts, you can read in this material (link).

The ratio of the amount of oil and gasoline for the fuel mixture

The proportion of oil and gasoline for a chainsaw is usually made up according to two recipes:

- 50 servings of gasoline per serving of engine oil

- 40 servings of gasoline per serving of engine oil

If the chainsaw was recently purchased and has not yet been operated, then the share of lubricant is increased by a quarter. The same amount is poured into fuel when cutting at temperatures below 2 degrees.

It is not difficult to get such a mixture. Almost every modern saw is equipped with a special two-section container. Oil is poured into a smaller part of it, and gasoline is poured into a larger part. The lids of both parts are tightly twisted and the container is turned over, shaken thoroughly. This achieves a complete and homogeneous mixing of both components.

If there is no such special container, then you can use any gasoline-resistant plastic container with a one-liter lid and a disposable syringe for 5-10 cubes. The tank for gasoline must first be cleaned of various pollutants and water. After that, one liter of 92-95 gasoline is poured into it.

In parallel, 20 ml of oil is drawn into the syringe. If refueling is done in cold weather, then you need to take 24-30 ml. We carefully pour it into a container with gasoline. It is tightly closed with a lid and shaken thoroughly until the components are completely mixed.

What oil to use?

The oil, as already mentioned, should be for two-stroke engines. over, it should be suitable specifically for chainsaws, as indicated on its packaging. There are just two-stroke oils, for example, purely for boat motors or scooters. They should not be used, since the operating mode of such equipment is not so intense, therefore, the requirements for oil are somewhat lower.

At the same time, there are oils where it is indicated that they are suitable for both chainsaws and boat motors and scooters. This oil can be used. But if it is only for boat motors or scooters, then it is impossible.

Correct proportions

So, I will not beat around the bush for a long time, but I will go straight to the numbers. The most common dilution ratios are 1:50 and 1:40. That is, one part of oil is poured into 50 or 40 parts of gasoline. For those who did not understand, I will explain in more detail. We take one liter of gasoline and divide it by 50 or 40, respectively. As a result, we get the right amount of oil for one liter of gasoline. That is, one liter is 1000 ml. Divide 1000 ml by 50, we get 20 ml of oil. Divide by 40, we get 25 ml. This is exactly how much oil you need to add to one liter of gasoline.

But you will say that you do not know what the proportion should be on your chainsaw. Well, if you have lost the instruction or for some reason there is no information about the proportion in it, then you can use the following rules:

- if the chainsaw and oil are from the same brand (for example, Stihl chainsaw and Stihl oil), then dilute gasoline with oil in the proportion indicated on the oil (usually 1:50);

- if the chainsaw and oil are of different brands, then observe the ratio of 1:40;

- if the brand is the same, but there is no information on the oil, then dilute in a ratio of 1:40;

- if nothing is known at all. you do not know the brand of the chainsaw or the oil., then you still dilute in a ratio of 1:40. The main thing is to know that the oil is exactly suitable for two-stroke engines of chainsaws.

If the saw is new and runs in, it is recommended to increase the amount of oil for the first three fuel tank fillings by about 20%. That is, the proportion of 1:50 turns into 1:42, and 1:40 into 1:33. Or 24 or 30 ml of oil per 1 liter of gasoline, respectively. Well, I note here that in addition to increasing the amount of oil in the fuel mixture, no more running-in measures with a chainsaw need to be carried out, unless otherwise indicated in the instructions. That is, it is not necessary, for example, to leave it idling for a long time or to cut it not at full speed, as this will lead to its overheating and faster failure. Always cut only at maximum speed. And after running out of three tanks of fuel (meaning the tank of the chainsaw), go to the usual proportions of 1:50 or 1:40.

But sometimes it happens that the manufacturer indicates a different proportion, compared to those that I gave above. For example, 1:25 or 1:32. In this case, these proportions must be observed. Although if you know about them, then what did you forget in this article?

How to mix gasoline with chainsaw oil?

To mix ingredients you need:

- Use a clean, dry container, measuring cup and graduated bottle.

- It is necessary to mix in a separate container, and not in the saw’s gas tank.

- First, pour in half of the gasoline, then the oil, shake everything well, add the second part of the gasoline and mix again.

Every tool owner should know how to dilute gasoline with chainsaw oil. However, the correct proportions are not yet a guarantee of a good mixture. It is important to select quality products so that gasoline and oil are homogeneous fluids and do not contain sediment. It is better to prepare the mixture before starting work. Although, according to the standards, the finished fuel and lubricating fluid can be stored for a month, but its properties deteriorate over time.

How to dilute gasoline with chainsaw oil

The chainsaw is used when cutting trees, in repair work. The popularity of this tool is growing every year. Each owner buys it for his own house. However, in order to use it for a long time, it is necessary to properly care for the instrument. Only with good care will the saw serve a long life and will not harm your health.

This is especially true in a gasoline-oil mixture. It must be diluted and poured strictly according to the instructions that will be given below.

Shelf life of ready-made fuel mixture for chainsaws

So, pure gasoline can be stored not very long, and the ready-made fuel mixture is even less. Some manufacturers indicate that in a diluted state, storage up to one month is allowed.

But experts recommend storing no more than 8-10 days.

It’s just that as soon as you mix, the oil immediately begins to gradually lose its properties. As a result, after a few days this fuel mixture is not the same as it was originally. What can we say about storage for more than a month.

Therefore, do not prepare the mixture for future use. You need to cook as much as you are going to use for the upcoming work. How much needs to be prepared in this case, only experience can tell. If you still do not have enough of it, then prepare no more than one liter of the fuel mixture. If it is not enough, then cook some more. it will not take long. If it remains, then it will not be such a large number as to regret it.

Store the ready-made fuel mixture in a closed opaque container. Or, if the container is translucent, then put it in a dark place. The container must be petrol resistant. For example, plastic bottles from various drinks (“poltorashki”) will not work. Their plastic is eaten away by gasoline and all this stuff gets into the engine.

You can use special metal or plastic canisters for flammable materials. Or just use an empty canister from any used oil, having previously rinsed it from the inside with clean gasoline several times. Glass containers will work too, but keep in mind that they are easy to break.

How to use a tachometer for a chainsaw

The multifunctional tachometer / hour meter is designed to measure the rpm of 2 or 4-stroke gasoline engines, their operating time and counting the time until maintenance (MOT).

Measurement range 0. 20,000 rpm

Powered by a replaceable CR2032 battery.

Equipped with green backlit display.

Wire length 1.5m.

Dust and moisture resistant IP68.

The charge indicator will promptly notify you of the need to replace the battery.

70 ° 70 ° maximum viewing angle will keep you from missing the essentials.

Two mounting options: quick release Velcro or screw studs.

Compatible with 9 types of engines.

View all tachometers

Instruction / manual of digital tachometer for PLM, chainsaw, motorcycle, scooter, ATV

For the tachometer to work, it is necessary to wind 5-6 turns / revolutions with a red signal wire around the high-voltage candle wire, and connect the second wire from the tachometer to ground or “minus”.

Switching between operating modes is carried out by short pressing of the MENU button.

To enter each mode and change its settings, press the MENU button and hold it pressed for more than 2 seconds until the indications of the selected mode start blinking or reset to zero.

To change the readings, shortly press the SET or MENU buttons.

Operating modes of a digital tachometer for PLM, chainsaw, motorcycle, scooter, ATV

1.Hour meter.

2.Tachometer.

RPM: tachometer mode. While the engine is running, the device automatically switches to the tachometer mode and displays the current number of revolutions per minute produced by the engine. When the engine is stopped, the device automatically switches to the display mode of the cumulative operating hours counter TOT.

MAX RPM: current maximum engine speed. This mode displays the maximum engine speed since the reset. To reset the data and start a new measurement, while in the selected mode, press and hold the MENU button until the readings are zero.

RPM ALERT SETTING: maximum allowable (critical) engine speed.

3.Other modes.

Motor type selection mode: By default, the 1P1R type is set. 1 spark per 1 revolution. Hold the MENU button until the default values start blinking. Select your engine type by pressing the SET button.

Possible installation options:

1P1r = 1 spark per revolution (4-stroke 2-cylinder engine or 2-stroke 1-cylinder engine)

2P1r = 2 sparks per revolution (4-stroke 4-cylinder engine or 2-stroke 2-cylinder engine)

3P1r = 3 sparks per revolution (4-stroke 6-cylinder engine or 2-stroke 3-cylinder engine)

4P1r = 4 sparks per revolution (4-stroke 8 cylinder engine)

6P1r = 6 sparks per revolution (4-stroke 12 cylinder engine)

8P1r = 8 sparks per revolution (4-stroke 16 cylinder engine)

3P2r = 3 sparks per 2 revolutions (4 stroke 3 cylinder engine)

5P2r = 5 sparks per 2 revolutions (4-stroke 5 cylinder engine)

1P2r = 1 spark per 2 revolutions (4-stroke 1 cylinder engine)

Note.

| Chainsaw carburetor adjustment The carburetor has three adjusting screws: L. low speed jet screw H. high speed jet screw T. idle speed adjustment screw Using the screws H and L, the ratio of the fuel-lubricant mixture and air is adjusted by opening the throttle valve. When the screws are tightened (clockwise), the mixture becomes leaner. low revolutions, when the screws are unscrewed (counterclockwise), the mixture is enriched, the revolutions increase. Screw T adjusts idle speed. |

First adjust screw L, then H and finally screw T.

First you need to find the highest idle speed by slowly turning screw L clockwise (or counterclockwise). After finding the position of the highest revolutions, turn the screw L 1/4 turn counterclockwise. If at the same time the chain rotates at idle speed, turn the screw T clockwise until the chain stops.

Adjusting the H screw affects power and rpm. Lean carburetor adjustment leads to excessive revs and saw failure.

After warming up the engine at full speed for 10 seconds, turn the screw H by 1/4 turn counterclockwise. Let the engine run for about 10 seconds. Check the maximum speed with a tachometer. Repeat the operation if the maximum speed does not correspond to the passport one. The engine should sound like a four-stroke. The saw squeals when the mixture is too lean. When the carburetor is adjusted to a too rich mixture, the muffler starts to smoke.

For optimal adjustment, you must contact a specialist with access to the tachometer.

Fine adjustment of the idle speed with the T screw is carried out after adjusting the L and H screws.

if it is necessary to adjust the idle speed, then with the engine running, the screw T must be turned clockwise until the saw chain starts to rotate. Then you need to turn the screw back counterclockwise until the chain stops rotating. The idle speed is set correctly if the engine runs uniformly in all positions with sufficient reserve of revolutions when the chain starts to rotate.

In a chainsaw, a lot depends on the carburetor: stable operation regardless of speed, tool power, economy of use, fuel consumption. In addition to the fact that the carburetor needs to be monitored, it also needs to be properly adjusted for the chainsaw to function properly. Setting up the carburetor on a chainsaw, as on any other unit, is a very complicated matter, and it requires a thoughtful approach and following the instructions. But if you clearly follow all the necessary instructions, then adjusting the carburetor is feasible for almost any person, and it must be done at the first sign of improper operation of the chainsaw.

Before proceeding with the adjustment of the carburetor, you should study the instructions for the chainsaw, and especially the part that describes the correct setting of the carburetor.

To set up safely, follow these simple rules:

- Place the chainsaw on a flat and stable surface (rack, workbench);

- Direct the chain away from yourself and other people;

- There must be a safe distance between the working chain and any surrounding objects.

Adjusting a partially or completely misaligned carburetor

After maintenance, such as disassembly and flushing, or previous unsuccessful attempts to tune, this assembly may become completely misaligned. So much so that the chain saw won’t start at all. In this case, it is necessary to configure the device of the engine power system in 2 stages, conventionally called:

- basic. with the engine off;

- final. produced on a warm engine.

At the first stage, the adjusting screws “L” and “H” are slowly screwed in the POCHS until it stops. In this case, you do not need to make great efforts and try to tighten them. Then we turn both screws back. for many models of saws by 1 revolution. And for some. by 1.5 turns. There may be other settings as well. This must be clarified in the technical documentation for the chainsaw. For a number of models, the tip is printed directly on the cover of their case near the adjusting screws.

This will perform the recommended factory default carburetor setting. In this case, we do not touch the screw “S” (“LA”, “T”), unless of course it has already been turned. When it is already twisted, you will have to work with it. Slowly screw in the “S” PRChS until it stops.

Let’s move on to the final stage. We are trying to start the engine. If there was no manipulation of the adjustment “S” (“LA”, “T”) and exactly as recommended, set “L” and “H”, then it should start.

If “S” had to be tightened for the above reasons, then the engine, most likely, will not start right away. After each attempt, it will be necessary to tighten this screw by 1/4 of the POCHS turn and try to start the engine again. In the end he must earn.

Then we warm up the engine for 10 minutes. If after starting it or in the process of warming up the motor is unstable or the chain starts to move, then it is necessary to slowly and carefully rotate “S” (“LA”, “T”) PRChS. As soon as the engine starts to work steadily and / or the chain stops, we immediately stop the adjustment. If the engine stalls, then turn this screw by 1 / 8-1 / 4 (see technical documentation) of the POChS turnover.

In the process of warming up, the idle speed may begin to increase, then, again, it will be necessary to “S” (“LA”, “T”) start slowly turning the PRCHS until they become normal by ear. On an already warmed-up engine, we continue to adjust the power supply system assembly, as described in the previous chapter.

When to adjust the carburetor?

There are several signs that help you understand that you need to adjust the carburetor on your chainsaw, these signs are listed below:

- The factory settings of the chainsaw were changed due to the weakening of the carburetor adjusting bolt;

- The cover of the UPT case is damaged;

- The engine starts poorly or does not start at all;

- the chainsaw does not keep idling or is unstable at idle;

- the exhaust of the chainsaw is too thick;

- excessive consumption of fuel;

- spark plugs quickly turn black or become covered with a white coating;

- the chainsaw does not gain the declared power characteristics;

- during a set of revolutions, the chainsaw engine stalls;

- the chainsaw vibrates strongly at idle;

Of course, these reasons can be caused by other problems with your chainsaw, and in order to eliminate unnecessary, you need to take a number of measures. If dirt gets into the fuel system, then the engine can also jump at idle and in this case you just need to flush it. If your piston group is worn out, then power is lost, but in this case, when idling, you will hear a characteristic knock. you need to change the piston group.

Same. you will need to adjust the carburetor if you start using a different fuel, or use the chainsaw in other atmospheric conditions.

Carburetor adjustment in case of changing operating conditions

In this case, you do not need to identify a breakdown, and the carburetor is adjusted so that the chainsaw can work in new conditions. First, start the chainsaw and let the engine warm up for 10 minutes. After that, you need to determine the position of the idle screw so that the speed is maximum. To do this, very slowly and smoothly turn the screw in one direction, then in the other, and so on until the required position of the screw is found. After that, turn this screw a quarter of a turn counterclockwise (hereinafter PRCHS).

Then continue adjusting idle speed using screw “S”:

- If the chain, after manipulating the first screw, is stationary, then you need to smoothly rotate the screw “S” clockwise (hereinafter POChS) until it starts to move, and then tighten the screw “S” a quarter of a turn in the opposite direction;

- If the chain moves, then you need to rotate the screw “S” of the PRChS until the chain stops, and then tighten the screw “S” a quarter of a turn in the same direction.

After this adjustment, the motors should run smoothly and the acceleration of the motor should be normal. Normal acceleration of the engine is when, when you press the fuel button, the revolutions reach maximum values without dips. If the engine does not run smoothly or accelerates very poorly, then you need to tighten the screw “L” by 1/8. After that, you need to perform the above-described adjustment of the screw “S”. These manipulations must be repeated until the engine starts to run smoothly and acceleration is normal.

After that you need to check the setting of the bolt “H”. To check it, you need to accelerate the engine to maximum speed. Be sure to pause and do not hold the maximum RPM without load for very long. Watch for exhaust and engine sound. If a lot of bluish smoke comes out of the muffler and the engine is running very loudly, then your carburetor is making a very rich mixture. In this case, you need to turn the “H” bolt by a quarter of the POC. Then again check the operation of the engine and repeat the adjustment if necessary.

When the chainsaw makes a squealing sound, the engine is very hot, the exhaust is accompanied by a crackling and / or interruptions in the ignition are heard, that is, there is a detonation. the mixture is too lean, and the maximum engine speed is higher than it should be. This leads to overheating of the power unit, piston burnout, rapid cylinder wear and spark plug burnout. In this case, it is necessary to turn “H” by 1/4 turn of the PRCHS.

At the end of the adjustment, we check the saw at idle speed. With a properly adjusted DCL, it should work like this:

- 1. The chain is motionless.

- 2. The sound of the engine is almost like a four-stroke.

- 3. Pressing the accelerator leads to a quick set of maximum revs.

If these conditions are not fully met, you should use “S” (“LA”, “T”), as indicated above, or repeat the setting from the very beginning.

This is a rough adjustment. For accurate, you need a tachometer. We do all the same, only we turn the adjusting bolts, focusing on the readings of this device. This will allow you to accurately and, most likely, the first time to adjust the carburetor, having achieved, depending on the model of the tool for working with a tree, the setting of idle speed at 2800-3300 rpm or higher and maximum. 11000-15000 rpm. Which ones should be set, you need to look in the technical documentation (operating instructions) for the saw.

Carburetor parts, preparation for tuning and safety measures

Before adjusting the carburetor, you should definitely make sure the air and fuel filters are clean. Also, make sure that there is no air leakage into the motor from the side, otherwise it will not be possible to correctly adjust the carburetor.

Almost any carburetor in a chainsaw is adjusted using three screws:

- The main jet bolt, which is usually indicated with the letter “H”, is used to set the maximum engine speed;

- The idle jet bolt, which is designated “L” and used to set low or idle speed;

- Idling adjustment bolt, which is designated differently: “S”, “LA”, “T”

Of course, you can find carburetors with fewer screws. Such carburetors, as a rule, are specially designed to protect their products from incorrect settings.

Adjusting the carburetor after running the chainsaw

After running the chainsaw, it is imperative to adjust the carburetor. In this case, you will definitely need a tachometer and technical documentation from the chainsaw used. The fact is that when running in a chainsaw engine, several different carburetor settings are used, which are configured to prepare a slightly richer mixture, unlike that one. which is used in constant work. Engine break-in takes place in a gentle mode and therefore after it you need to reconfigure the chainsaw engine.

It is highly recommended to mark the bolt positions before adjusting the carburetor. With the help of the marks, in case of an unsuccessful attempt, you can return them to their original place and start setting up again. The adjustment should be started with bolt “H”. After you have set the maximum speed, check the idles. If they are different from normal, then first expose them with “L” and then “S”. But turn the screws. focusing on the tachometer readings.

Good afternoon, I have a Motor Sich 270 chainsaw, is there a method for adjusting the carburetor using a tachometer? And how to do it practically?

take any instructions for setting up the carburetor and everything is written there. if there is no instruction, then you turn the screws half a turn in one direction or another and you catch the stable and powerful work of the engine. one screw is responsible for dips and the other for power

First you need to decide if we need it? usually everything works fine

And if we decide what is needed on a warm engine, we gas and measure the speed, turn the screw “H” aka “1” to get 12500

Read Mona here: “

Thanks for the advice, here’s another problem, unstable idle speed, after adjusting the carburetor, I used up half of the fuel tank, and it started, then the speed drops, then increases, you have to constantly adjust the XX lower screw. Who has already faced such a problem?

Aleksej1 wrote:

then the revolutions fall or increase, you have to constantly adjust the XX with the lower screw.

try “L” to add

carburetor tuning topic “

Aleksej1 wrote:

Thanks for the advice, here’s another problem, unstable idle speed, after adjusting the carburetor, I used up half of the fuel tank, and it started, then the speed drops, then increases, you have to constantly adjust the XX lower screw.

For MS saws. crap is understandable, there the whole saw is a continuous crap. Our forestry threw them out, then they bought them for us, so they didn’t really saw it. Throw it away right away and buy a huska or dude.

Aleksej1 wrote:

Good afternoon, I have a Motor Sich 270 chainsaw, is there a method for adjusting the carburetor using a tachometer? And how to do it practically?

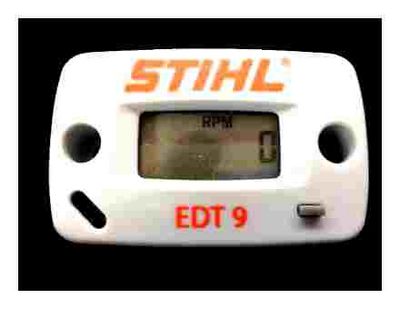

Using the Stihl EDT 9 Tachometer on Stihl 028 Chainsaws

But I remind you. that the advice will most likely not suit you, MS is a unique saw, I think that even having adjusted the speed, it will not cut, at least for a long time.

The MC file itself is not badly conceived, and with a tuned carburetor it works no worse than import, I saw it myself, only the carb is very moody, requires a special approach

pelipenko wrote:

For MS saws. crap is understandable, there the whole saw is solid crap

so that this does not need to shake the sawdust off the head and hands need to grow not far from the head

pelipenko wrote:

A tachometer is not needed here or is useless. the minimum speed for a saw is when the chain does not rotate on a warm engine, but the engine runs stably

all this is set up without a tachometer by adjusting the behavior of the engine as an indicator of throttle response and movement of the chain along the bus, with quality screws for unomarks L for MS X (aka 2), during the adjustment process, you need to achieve normal fast acceleration without dips and then with a screw for overseas T for MS Xs (aka 3) set the idle speed, first twist it until the chain moves, then unscrew it to stop it. to check, you need to turn off the saw a couple of times and start it in hot start mode, press the gas if the engine starts normally and accelerates, then the adjustment is correct.

if your saw stalls at idle, start first by adjusting the screw for the amount of Xc, and if it does not help, then you need to work with the screw X (2)

pelipenko wrote:

Another adjustment: this is the cutting power, i.e. at full throttle with the P screw, you achieve maximum performance, in principle, by sound, or try.

and here we need a tachometer with its help we set 12500 rpm how to do it I wrote above.

and if you have not felled the forest with this saw for many years and you do not have a perfect ear for music, then no sound.

because the cutting speed is achieved in two ways: 1 by sharpening or replacing the chain. 2 engine revolutions (increasing them). the increase in speed is achieved due to the depletion of the combustible mixture, while we obtain a decrease in the amount of lubricant and at the same time, increased heating of the engine, as a result, death comes to the engine

pelipenko wrote:

But I remind you. that the advice will most likely not suit you, MS is a unique saw, I think that even having adjusted the speed, it will not cut, at least for a long time.

do not frighten a person for nothing, 2 soveysky Urals passed through my hands 1 Chinese vorskla and an electric ruby, I can’t say that the forest is its currency, but the motor sich is the best of the listed, the only drawback that I found in 2 years of operation is the weight it is one and a half kg heavier than 440 calm. you don’t need to take into account this elecro

Stihl EDT 8 Tachometer

Aleksej1. I will repeat and lay out the address where Mona can download and read “

Chainsaw tachometers

The most common devices for monitoring the engine speed of a chainsaw are wired models. Their popularity is due to their low price. Various models of electronic tachometers for chainsaws from the Chinese manufacturer Runleader now cost 950-1850 rubles.

To measure engine speed with such a device, it is necessary to provide access to the high-voltage wire of the spark plug, which (depending on the model) can be connected in two ways:

- using the clip located at the end of the supplied cord;

- using a winding (5-6 turns of the free end of the cord around the high-voltage wire), fixed with a plastic clamp or insulating tape.

What to look for before starting adjustment work

Before starting any adjustment work, you must carefully read the instructions for the chainsaw. It indicates the engine speed (idle and maximum allowable), which must be set when adjusting the carburetor for the correct operation of the tool. The period of uninterrupted operation largely depends on this.

The air filter must be thoroughly cleaned or replaced. You should also make sure that the candle is in good working order, and the required gap between the electrodes is set.

Important! Before starting the setting, we warm up the saw at idle speed for 8-12 minutes.

In what cases is it necessary to adjust the carburetor of the chainsaw

Along with such preventive work as replacing the spark plug, fuel or air filter, it is periodically necessary to adjust the carburetor of the chainsaw. This must be done when:

- the new chainsaw is unstable on the fuel available to the user;

- the saw will not start;

- overestimated or underestimated idle speed;

- the saw starts up and immediately stalls;

- the fuel consumption declared by the manufacturer has increased significantly;

- when loosening the fixation of one or more adjusting bolts;

- after repairing the carburetor or replacing it with a new one.

Chainsaw carburetor adjustment using a tachometer

The largest number of chainsaws “Husqvarna”, “Stihl”, ‘Partner “,” Champion “(as well as from numerous Chinese manufacturers) has three spring-loaded adjusting screws on the carburetor.

They are designated by Latin letters and are intended:

- L. to adjust the fuel supply at low revs.

- H. to set the amount of fuel at maximum speed.

- T (for some LA models). decrease or increase the supply of the air-fuel mixture at idle.

For the production of work, you will need a thin slotted screwdriver and a tachometer to adjust the chainsaw.

On a note! For the convenience of counting the turns of the adjusting screws, it is better to pre-apply a clearly visible mark on the screwdriver handle.

The tuning algorithm is pretty simple:

- If a wired tachometer is available, remove the protective cover and air filter to provide free access to the high-voltage wire. This is not necessary when using a wireless meter.

- We start the chainsaw.

- We connect the tachometer (or bring the wireless device close enough to the candle).

- By turning the screw L, we achieve the highest idle speed. Then do ¼ turn counterclockwise.

- If the chain moves in this mode, then by rotating the screw T (LA) we achieve its complete stop.

- Press the accelerator handle all the way.

- Let the saw run in this mode for 8-10 seconds.

- According to the readings of the tachometer, use the screw H to set the maximum speed recommended by the manufacturer.

- Adjust the required idle speed with the adjusting bolt T.

- By pressing and releasing the throttle handle, we make sure that the tool works smoothly in all modes, without dips and jerks.

- Turn off the tachometer.

- Reinstall the air filter and protective cover.

Setting up carburetors of low-power chainsaws

On low-power chainsaws (for example, the rather popular models MS170 and MS180 from Stihl with an engine volume of 30-32 cm³), carburetors with only one adjusting screw are usually installed.

On the case it is designated by the Latin letters LD. It is designed to adjust the engine idle speed. The adjustment of such a carburetor can be done both with and without a tachometer for measuring the speed of the chainsaw:

- we tighten the adjusting bolt all the way;

- we unscrew it two turns;

- start the chainsaw.

If the idle speed is too low (as evidenced by the tachometer readings or unstable engine operation), then turn the screw until the saw chain starts to move. Then we unscrew it ½ turn back (that is, in the opposite direction).

If the idle speed is overestimated, and the chain starts to move immediately after starting the engine, then we rotate the screw until it stops and make another ½ turn in the same direction.

Wireless Engine Speed Meters

convenient to use are tachometers for chainsaws, which allow monitoring the engine speed without connecting a wire. Such measuring devices measure the engine speed at a distance of 15-20 cm from the insulating spark plug cap. The undoubted advantage of such measuring devices is that when adjusting the carburetor, there is no need to dismantle the protective casing and the air filter. But these devices are much more expensive than their wired counterparts.

On the Russian market, the most affordable are wireless tachometers from the leading manufacturers of chainsaws “Husqvarna” and “Stihl”: Husqvarna PET-302 and Stihl EDT-9.

These devices are pretty versatile. Measurements can be taken at various distances from the candle cap:

- at a distance of 5-10 cm, when using only the device itself;

- 15-20 cm by connecting a short antenna wire (15 cm long) to the device;

- 1.2 m using a test cord with a clip for attaching to the spark plug high-voltage wire.

Chainsaw tachometer. How to tune a chainsaw carburetor using a tachometer

Hand-held chainsaws are now widely used both for felling trees, cutting knots and further harvesting firewood, as well as in the construction of wooden houses and various buildings for household purposes. Like any other tool, these devices (quite reliable) require regular maintenance and sometimes adjustments. For example, a tachometer for a chainsaw will allow you to easily not only check the characteristics of a newly acquired tool, but also make subsequent adjustments to the carburetor yourself.