Lawn mower led lights. Lawn mower led lights

ROPS Lights LED Worklight Kits for Zero-Turn Mowers

Ariens, Bad Boy, BigDog Mowers, Bobcat, Bush Hog, Country Clipper, Cub Cadet, Dixie Chopper, Dixon, Encore, Exmark, Ferris, Grasshopper Mowers, Gravely, Hustler Turf Equipment (Excel Industries, Inc.), John Deere, Kubota, Scag, Walker, Snapper, Toro, Troy Built, Wright Commercial Mowers, Yard Shark

ROPS Lights Double LED Mower Worklight Kit

ROPS Lights Zero-Turn Mower Battery Connection Kit

ROPS Lights LED Worklight Kits for Virtually All Tractors and Mowers

ROPS Lights manufactures LED worklight kits for virtually all makes and models of tractors and mowers that have a Roll Over Protection Structure (ROPS). We simply can’t list all of our models in the dropdown menu. If you need a ROPS Lights LED worklight kit for a tractor or mower that isn’t listed, just select “Other Tractor or Mower” from the dropdown menu and enter your model in the ENTER MODEL box. We’ll make sure to send you the right kit.

LED Worklight Kits for All Tractors and Mowers

ROPS Lights makes LED worklight kits for virtually ALL tractors and mowers that have a Rollover Protection Stucture (ROPS). We’ve listed only a few here on the website. If you have a tractor or mower not listed in the dropdown menu, just type your make and model number into the “ENTER MODEL” box and we’ll be sure to send you the correct kit for your tractor or mower.

Same Day Shipping!

If you order a ROPS Lights LED worklight kit today, chances are we’ll ship it to you today!

We pay the HST on ALL Canadian Sales! U.S. and International customers don’t pay HST either.

Please expect some shipping delays during the holiday season.

ROPS Lights LED Mower Worklight Kits Come With Free Battery Connection Kits

For mowers that do not have a dedicated worklight connector, we include a free battery connection kit with a built-in fuse, making it easy to connect a ROPS Lights LED worklight kit to virtually any mower.

Lawn mower led lights

When I replaced my 30-year old rear-discharge Wheel Horse Lawn Tractor, I had difficulty finding a suitable replacement. The only rear discharge mower I found was the John Deere X350R which has a 42-inch rear discharge mower with a bagger. However, it gives less than satisfactory results without the bagger which is included whether you want it or not. I settled on a John Deere X350 with 48-inch side discharge mower and mulching kit. Then I removed the side-discharge shoot since I keep the mulching bypass closed. This is my version of a John Deere rear discharge mower and it cost 600 less than the X350R. However, many John Deere lawn tractors have serious deficiencies including my X350.

- The headlights were very dim. John Deere uses a standard automotive brake light bulb in a crude reflector. It was difficult to see and be seen by cars when working in the late evening.

- There were no tail lights or reflectors on the back. Again, this is important when I am working near a road in the late evening and I need cars to be able to see me.

- The steering is fantastic, but it takes 2 complete revolutions of the steering wheel to turn from the left lock to the right lock. This is difficult to do quickly and slows down otherwise quick turns.

- The hitch plate is only configured for a pin hitch, and not a ball hitch, tow-rope or chain.

- The battery had an insulating shield over the positive terminal that made connecting a trickle charger very difficult without distorting the shield.

- If I put on 4 suitcase weights,, they don’t slide around, but they block access to the hitch plate. With 2 suitcase weights, they would shift from side to side on hill sides and when I made turns. It wore the hitch plate where they slid and I lost a lot of the stability on hill sides I was trying to achieve by adding the weights.

All of these problems were remedied for less than 100. Listen up John Deere, you to can do this. Here is how:

Weak Headlights

Comparison of new LED lamp on left with the old lamp on right.

The weak headlights are understandable since they are only standard 1156 automotive brake lights. There are LED lights that fit in the same socket and use much less power and also give off much more light. With High Power LED replacement bulbs, it is much easier to see far ahead and in the immediate front.

| Lamp | Power Consumer | Light Output | Cost for pair |

| Standard 1156 brake bulbs | 26.9 Watts | 402 lumens | 4 |

| 1156-7506 LED replacement bulbs | 6.5 Watts | 1,500 lumens | 30 |

These are 3030 SMD High Power 1156 7506 LED Bulbs available from jdmastar.com.

Comparison of new Hi Power LED lamp with the old lamp.

There is a trick to switching to the LED bulbs. The LED bulbs required the base center pin to be positive. John Deere wired the base center pins of the bulb holders to be negative. Hence, I had to switch the positive and negative wires on each bulb holder. However, one bulb holder tab is wider than the other to keep them from being reversed. I clipped one side of the wide tab so that I could reverse them. Then the black/white wire is attached to the tab on the bulb holder at the base end of the bulb.

Reflectors

The rear view of the tractor with stick-on reflectors added.

There were no lights or reflectors on the rear of the John Deere tractor. I simply bought a pack of 2 stick-on reflectors from Harbor Freight for 3 for the pair. I will discuss the tail light in the section on Suitcase Weights.

Steering

The steering wheel with the John Deere spinner.

I really like my John Deere’s very small turning radius, but it takes 2 complete revolutions to turn from the left lock to the right lock. It also takes two hands. On side hills, I am using one hand to position myself on the uphill side of the seat for comfort and stability. (I had to disable the seat switch to permit sitting on the uphill side of the seat while mowing.) Being able to turn the steering wheel quickly with one hand was easily facilitated with a spinner knob on the steering wheel. I treated myself to a John Deere Spinner Knob for 16. It has a hard rubber mount that doesn’t damage the steering wheel.

Hitch Plate

The hitch plate with the Hitchin Post attaced to the pin hole.

With my Wheel Horse, I used a small utility trailer that has a ball hitch. Also, I like to be able to move trailers with my lawn tractor. My other attachments had pin hitches. Frequently I used the tractor to pull things with tow-ropes or chains. The John Deere only had a pin hitch. This is easily remedied with the Good Vibrations 3-Way “Hitchin Post” which cost me 25. The ball is extra. When using a ball hitch, get one with a 3/4 in. shank diameter, and 1-3/4 in. shank length. If the shank is longer, it won’t fit.

The Good Vibrations 3-Way “Hitchin Post is available from Tractor Supply Company.

Battery

The battery on the left and a charger plugged into the Power Outlet.

When I store my lawn tractor for a month or more I always connect a trickle charger to maintain the battery. In the winter, I always use a trickle charger to keep the battery from discharging. This is extremely important since once a battery discharges it can freeze. Freezing will destroy a battery. With the insulating shield John Deere uses on the positive terminal it is difficult to repeatedly attach charger cables without eventually damaging the insulating shield. It is easy to attach charger cables to the battery using the John Deere Power Port Outlet Kit that fits into a built-in hole below the steering wheel with a pop-out plug. It makes it easy to plug in the cigarette-lighter type plugs. Fortunately, it is not connected to the battery through the power switch, hence, when the tractor is in storage the Power Port Outlet can be used to connect a trickle charger. Most trickle chargers come with a plug type connector which plugs right into the John Deere Power Port Outlet. My power outlet kit cost 14.

The John Deere 12-Volt Power Port Outlet Kit is part # BM24915.

Suitcase Weights Tail Light

Suitcase weights with a board bolted between them.

Since I both mow grass and plow snow on side hills, I keep a pair of chains and 2 suitcase weights on all year. With the 48-inch mower this is no problem; there is plenty of clearance for the chains. The problem I did run into is that with just 2 suitcase weights, the weights slid from side to side as I turned and went on side hills. With 4 weights, they wouldn’t slide but I would lose the functionality of the hitch. The sliding was easily remedied by bolting 2 pieces of wood to the hitch plate between the two weights, one behind the plate and one in front of the plate. I used pieces of scrap lumber, so this didn’t cost anything.

The wood board between the suitcase weights provided an easy place to mount an LED tail light. I purchased a.25 Watt LED tail light from Walmart for 19. I could have easily plugged the LED tail light into the Power Port Outlet in the Battery section above, but that would have meant having a cord stretching in my way and it would need a switch to keep from being on all of the time. I elected to connect the LED tail light to the terminals for the right headlight. The two LED headlights and LED tail light resulted in power consumption dropping to only 1/3 of what it was originally, so power consumption is not a concern. light and less power consumption is a great improvement. Connecting the tail light to the right headlight provided automatic switching of the tail light with the headlights. To connect to the right headlight, I had to make a set of connectors to break out power for the tail light and then run a wire from the right headlight to the new LED tail light. This was not trivial, but I strapped this wire to existing cable runs to avoid making any changes to the cabling layout. I started going back along the headlight cabling and ended up going back along the seat-interlock-switch cabling. Then it was just a short run above the gas tank to the LED tail light. I used a length of black oil-resistant CPE jacketed 16 AWG/2 stranded copper duplex (SJOOW) wire I purchased from Ace Hardware. It worked great and blended in with the John Deere cabling.

Blazer, 6-Function, LED, Submersible, 7-Diode, Red-Lens. Passenger-Side, # C7493RTM Trailer Tail Light from Walmart for 19.

The result:

The front and rear view with all of the following improvements.

The result is all problems were solved for less than 100. For an additional 19, I added a tail light for increased visibility to passing cars when I am plowing snow in the winter.

| Hi-Power LED replacement head lights | 30 | pair | jdmastar.com |

| Rear Reflectors | 3 | pair | Harbor Freight |

| Spinner Knob | 16 | each | John Deere |

| 3-Way Hitchin Post | 25 | each | Tractor Supply Company |

| John Deere BM24915 Power Outlet | 14 | each | John Deere |

| Scrap Pieces of Wooden Board | free | ||

| Blazer C7493RTM LED Tail Light | 19 | each | Walmart |

| Total | 107 |

Power consumption for the headlights and new taillight dropped from 26.9 watts to 6.75 watts and visibility increased by a huge factor.

My 48″ Accel Deep Deck with mulching kit is Zero-Discharge Mower!!

My 30-years experience with the Wheel Horse rear discharge mower had spoiled me. No clipping being blown into flower beds, on walks, or into the road. Without the proturding side discharge, I could mow right up to the sides of objects such as trees, mail boxes, fences and boulders. When clippings got so heavy, that they could smother the lawn if left, I could tow a very inexpensive lawn sweeper while I mowed and still have all of the advantages of a rear discharge mower.

The John Deere Zero-Discharge Mower

When I bought the John Deere X350 with 48″ Accel Deep Deck side-discharge mower with mulching kit, I assumed I was getting essentially a rear-discharge mower. What I got was a Zero-Discharge Mower. So far, even under worst case condition, I never see any brown clippings. They are chopped up so fine that they disappear into the turf before they turn brown. Before, when we had a picnic, I used to mow every 5 days for at least a month to get control of the clippings and make the lawn look good. Now, even after 3 weeks, I mow it once and it looks good enough for a picnic with out any brown clippings showing up.

I hope this is of help to someone else.

Proper DIY Guide on How to Wire Lights on Zero Turn Mower

Headlights on a zero turn? Do you really think you need it? But seriously though, putting headlights on your ZTR mower is not just for decoration, like headlights in a car, your mower needs one too. This is especially true for commercial zero-turn mowers. Mowing from dusk till dawn or into the evening to complete a mowing task is common for many residential lawn services. And to do that, you need to have full visuals on the lawn and the grass to mow effectively. To make it simpler and cheaper, here’s a quick guide on how to wire lights on zero turn mower yourself.

Do you really need headlights?

As I’ve mentioned, having full visuals of mowing the property is essential for those who can only mow their lawn in the morning or later into the night. But more than that, it’s also quite helpful when you’re navigating your way out and into your garage, barn, or storage area. It is also perfect when you’re hired to mow a field at night before a big game.

Whichever it may be, a simple set of headlights can really make a difference especially in taking an hour off mowing in the dark.

Benefits of Mowing When the Sun is Down

You don’t have to face the wrath of the sun at its high peak when you’re mowing at night. The air is cool and you don’t have to suffer getting any sunburns, prickly heat, or other sun-related skin problems.

The best time to mow your grass is when your property is completely free from any obstructions, with no kids playing around the lawn, or dogs constantly barking at your noisy mower.

How to Wire Lights on Zero Turn Mower

- Things You Need:

- A socket and wrench set (view on Amazon)

- Electrical tape

- Zip ties

- Wire strippers

- Wire crimpers

- Heat shrink butt connectors

- Driller (view on Amazon)

- Preparation:

- Before you purchase any lights for your mower, make sure to measure the spaces where you want to put them. The best places to put them are:

- over your front wheels

- right by the foot deck

- over your rear wheels

- by the end of your engine ( if your engine sits behind your seat)

- Measure the areas you want to fit your lights in before purchasing what kind of light you need.

- Mounting the lights:

- Prepare your mounting holes. If there are bolts over areas where your lights can fit, it’s best to remove the bolts instead of drilling holes in your mower.

- If you want to mount your light in places that don’t have existing bolts, simply drill just the right hole for your mounting bracket.

- Affix your mounting bracket on and bolt it on your mower.

- Position your lights and secure them with a bolt or a screw that came with them.

- Do this with all the lights you purchased for your mower.

- Creating your lightswitch:

- Go to your fenders and find the best spot to put your light switch. Most of the controls are found on the right fender, however, inspect the area to see if there’s a place where you can fit your light switch.

- Before choosing the best area, make sure that your light switch won’t tangle with other parts of your mower, if the control box contains too many wires, it’s best to fit your light switch elsewhere like the other fender.

NOTE: Some residential z-turn mowers have allocated slots where you can install upgrades on them. If the slot does not fit your light switch, you can drill a hole, or cut out a piece of your fender to fit for perfect fitting.

- Affix your light switch on the hole with its accompanying screws or bolt.

- Attach the hot wires on your switch, you can opt to secure it with electrical tape if that helps.

- Wiring your lights:

Single light:

- Layout your wiring harness from under the fender over your engine (if your engine sits under your seat) and over the mowing deck to your single headlight. Do the same thing to the back of your mower where you’ve placed your rear mower lights.

- Secure the wires together with electrical tape or heat butt shrink connectors.

TIP: I suggest you use a single bright color for your butt connectors. This will make it easier for you to find your wiring for the lights n case you may need to rewire your lights again in the future.

Multiple lights:

- Crimp your wires to each other and secure them.

- Once you’re finished, connect the crimped wires to the hot wires from your light switch.

- Layout your wiring harness around your engine and secure them properly.

- Lighting it up:

- Once you’ve cleaned up your wiring harness, attach the hot wires to your switch bolt.

- Then, you need to hook the battery cable to the bolt.

- Put the nut back on to secure the hot wires and the battery cable.

- Clean your area so you can test if the light is working.

- Turn on your ignition to power up your battery and switch the light on.

The Bottom Line

Installing and wiring your headlights is an easy task. The only thing you always need to remember is to keep your wires away from heating and moving parts of your mower. This is to secure your light as well as the main parts of your engine. Adding lights to your best zero turn mower is an essential upgrade that will surely lessen mowing time when the sun is about to set on your mowing job.

EL Mehdi (Medi), the founder and voice behind Desired Lawn Mower. He is a riding mower lover and has been active in the industry for years. He’s also an entrepreneur who owns and manages multiple helpful websites.

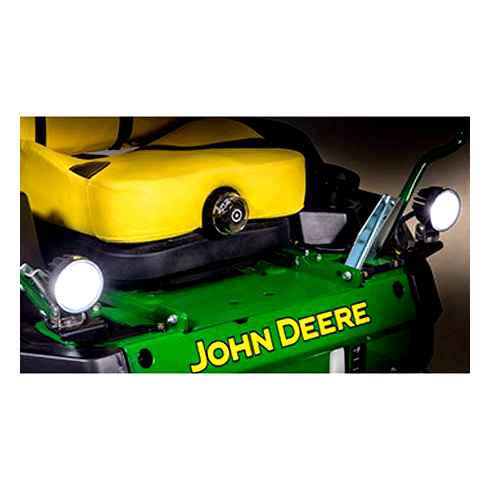

Z900 series zero turn lights

Good morning folks. I picked up a Z960M last week and am already looking for things to add to it. I fabricated a trailer hitch for small carts and trailers now I’m thinking about adding some work lights.

I know Deere offers a lighting kit for these mowers, my question is has anyone here installed this kit or has anyone taken some aftermarket LED lights and installed them? I’m inclined to go the aftermarket lighting route since there are many more lights available to choose from. Curious how it worked out and any lessons learned.

kbeaag

If you intend on mowing after dark, the light kit is in use, and the lights should be mounted up front on the frame like the instructions state. I don’t see them being very effective mounted on a higher area like on the “fel” brackets. There are many kits on ebay that are available for such demand. If you live in a close neighborhood and mower after dark, you might get some complaints.

zilla24

I’m not in a neighborhood so that’s not necessarily a concern, the lights are more of a I got a late start after work and need to finish kinda thing. Also I mow at other sites sometimes, lights would be nice to help loading before daylight.

I am a fan of where Deere mounts them just in front of the motion control levers in their kit, just not a fan of the 260 price tag and the lights don’t appear to be of very high quality.

sennister

I haven’t added them to mine. I did pick up a small light bar at HF a while back and may put them on the ROPS. Clamp mount of course, don’t drill into it.

The thing is, around here in the summer when the Z gets the most use, it is light pretty late. It isn’t like I am going around mowing at 10PM.

Where it would come in handy is mainly the fall during leaf harvest. Sunset around here in late October is 6PM and when dealing with leaf collection, you are tied a bit to the conditions. I don’t want to do it if they are too wet and if that means I have to do it on a weekday I don’t get home until 5PM most of the time. It isn’t that ridiculous to be out there say at 7-8PM in terms of disturbing neighbors and such but it can be plenty dark by then.

As far as cost. I know it looks like 260 is a lot. But those are LED lights. Sure there are cheap HF options out there. I have never installed these or worked with them but I can assume they are at least decent quality. Where I have installed LED lights similar to this is on Motorcycles. In that realm, 260 is a very cheap option. Here is an example of some that I have installed that are probably pretty close in size/output. Well they are a little more compact but twice as expensive.

Darla (Honda ST1300)

The Darla makes your motorcycle more visible to oncoming traffic during the day and at night provides a wide pattern of light which adds to side illumination. They are a combination of a fog and visibility light meant to make you more conspicuous.

www.clearwaterlights.com

JD Z950R 60″ Deck with DFS Collection System

JD X585, 54C deck, CTC Model X4750 F.E.L. Modified Imp Pressure Relief from 900 to 1175PSI, Power Flow and MC519 cart, 54-inch Quick-Hitch Front Blade, 47-inch Quick-Hitch Snow Blower, 3-pt hitch, HF Quick Hitch, Heavy Hitch, 48″ box blade/rear blade, Dethacher, 3pt Sprayer

zilla24

I guess you have a valid point, why cheap out on a 10k mower for 100 in lights.

Next question for those that have installed this kit, is it plug and play? Is the machine prewired for such an accessory?

sennister

I can’t 100% answer your question. My understanding is that there is a knockout in the panel for the switch. I don’t know that the wiring harness is prewired for this as I don’t think it is an item they sell a lot of. It likely just ships with a harness that hooks to the battery and is fused with an inline fuse.

I guess that is another advantage to spending 260 on this. The wire harness is going to be set up for this application. The switch included will fit the knockout. importantly it will ship with the brackets that would be needed to mount the lights. Sure something can be fabed up but not everyone has that capability. All that considered, the price is probably about right. Like you said what is an extra 100 over the price you were thinking on a 10K machine.

Installing 1156 LED Light Bulbs In My Lawn Mower

I often look at some of these things from the perspective of my time is worth something. If fabing up a bracket or learning how to create a wireing harness for something like this is something I want to do for an educational benefit then I am willing to devote more time to fabrication process. If it is something I don’t have time for or I have done before and the quality of something off the shelf makes sense for the application, I go off the shelf even though it might cost a little more.

As for something like this I am on the fence personally. I did buy a HF LED bar which might go on my Z950R, odds are it won’t. I mainly got it because I will find a use for it and it was on sale. If the lighting keeps being an issue I might pull the trigger on a kit like this. I will say that I like the idea of their LED light kit. When I bought my Z it was the halogen one like what Kbeaag posted that I didn’t like. I would go for personally fabricated over that. I kind of like the LEDs you posted. Time will tell. The last few years I have gotten by with a head lamp. While we have neighbors, we all have large enough lots where we are cutting several acres and it isn’t like we have street lights or other illumination. I don’t cut grass or pick up leaves past 9pm. None of the neighbors have little kids though. It really only is an issue late in the fall when I am trying to get the last of the leaves before snowfall.

JD Z950R 60″ Deck with DFS Collection System

JD X585, 54C deck, CTC Model X4750 F.E.L. Modified Imp Pressure Relief from 900 to 1175PSI, Power Flow and MC519 cart, 54-inch Quick-Hitch Front Blade, 47-inch Quick-Hitch Snow Blower, 3-pt hitch, HF Quick Hitch, Heavy Hitch, 48″ box blade/rear blade, Dethacher, 3pt Sprayer