Lawn mower maintenance schedule. How to Care For and Maintain Your Lawn Mower

Preparing a Commercial Lawn Mower for Spring

Warm weather is coming, have you done your lawn mower spring maintenance? If you want your mower to perform reliably and last for years, we recommend you follow these guidelines before you start cutting.

Lawn mower engine oil changes

The obvious point here is to complete an oil change at the intervals recommended in your engine manual. If you can’t remember the hour reading at your mower’s last oil change, stay on the safe side and change it, along with the oil filter.

How to change lawn mower engine oil

Easy-to-read and understandable engine oil change details are outlined in the engine manual for your unit.

- Stop the unit, wait for hot parts to cool and remove the engine key.

- Position a drain pan under the oil drain hose.

- Remove the drain plug and allow all oil to drain.

- Remove and discard oil filter and install a new filter. When installing a new filter, apply a thin layer of oil onto the oil filter gasket.

- Reinstall drain plug and tighten to specification.

- Remove cap / dipstick from engine oil fill port.

- Fill engine with oil of correct weight / viscosity rating and quantity.

- Reinstall cap / dipstick, wait a few seconds and remove. Check the oil quantity and make sure it’s within the markings on the dipstick. Ensure cap is secure before attempting to start the engine.

How to change lawn mower air filter

Details are listed in the lawn mower engine manual, but it’s as simple as removing the air filter cover from the engine and remove the air filter. If the engine air filter is soiled or damaged, dispose filter and install a new air filter; if air filter appears clean and in good condition, reinstall the filter. After filter is installed, reinstall air filter cover.

Hydro Gear transaxle maintenance

If you don’t remember when the transaxle oil was changed, err on the side of caution. Transaxle oil is a heat transfer, and once it breaks down, it’s no longer an effective lubricant for critical mechanical components in a transaxle. A new Gravely zero turn lawn mower will need the transaxle oil changed after the first 75 hours of operation, but then only every 400 hours after that.

Change Hydro Gear transaxle oil

Changing transaxle oil is just as easy as changing engine oil:

- Park the unit on a flat, level surface, wait for hot parts to cool and remove the ignition key.

- Place a drain pan under the transaxle being serviced.

- Remove the filter guard and filter from the transaxle. Dispose the filter; retain the guard.

- Remove the transaxle vent port plug and allow oil to drain.

- Wipe filter mounting surface clean and lubricate gasket on filter with clean hydraulic oil.

- Reinstall filter and filter guard.

- Add manufacturer’s recommended oil type and volume to the transaxle oil expansion tank until oil reaches top of vent port.

- Reinstall hydraulic oil vent port plug.

- Add oil to transaxle oil expansion tanks until fluid level reaches cold fill mark.

- Purge hydraulic oil system.

Purging Hydro Gear transaxles

When transaxle oil is changed, air s can get caught in the transaxles, requiring the need to purge air from the transaxles immediately after completing service. When purging is complete, recheck the transaxle oil expansion tanks and add oil so it reaches the cold fill line in each tank, if necessary.

The transaxle purge procedure is somewhat involved, so please refer to the operator’s manual for your unit for detailed illustrations and instructions. If the process seems too complex, please leverage the skill and experience of an authorized Gravely dealer.

Sharpening professional lawn mower blades

Sharp and balanced blades have a better cut quality and they reduce the need to mow the same area twice and waste time.

If there’s no access to a lift, blades can be accessed and removed easily after removing the mower deck. Gravely designed the process so one person can do it without special tools, but again, handling mower blades is a delicate process, so please turn to a Gravely dealer for service help.

Remove lawn mower deck

The steps below are an abbreviation of the procedure’s detailed instructions in the operator’s manual. As always, follow the safety instructions in the manual while completing service.

- Park the unit on a flat, level surface and remove the ignition key.

- Remove the left belt cover.

- Remove the spring from the anchor bolt to release PTO belt tension.

- Remove the PTO belt from the engine clutch.

- Raise deck to highest position.

- Loosen front jam nut on eye bolts to reduce deck lift assist spring tension.

- Remove lift assist springs.

- Place wood blocks under each side of deck.

- Lower deck to lowest position so deck rests on blocks.

- Remove hardware retaining deck lift links to deck lift brackets.

- Move deck lift links away from deck lift brackets.

- Slide deck out from under unit.

Removing lawn mower blades

Follow the safety instructions in the manual before starting a service procedure because the blades are sharp and can cut if not handled carefully.

- Rotate the deck so its underside is exposed.

- Position a wood block between baffle and blade to prevent blade from rotating.

- With either a breaker bar or an impact gun, remove hardware retaining the blades.

Inspect the blades for wear, cracks and damage. If the blade is worn too far, is cracked or damaged, dispose it. Blades that are dull but in good shape otherwise can be sharpened according to the manual’s instructions. Remember, the maximum amount of material that can be removed from a lawn mower blade over the life of that blade is one-half inch.

Checking lawn mower blade balance

Whether the blades have just been sharpened or not, they should be checked for balance before each season. To check blade balance, slide the blade onto a screwdriver, shoulder bolt or pin and position it horizontally. If the blade moves, it will need more material removed from the heavy end of the blade. After the blades pass the balance test, they can be reinstalled.

Remember to double-check the orientation of the blade when reinstalling. Blades must be installed with the cutting edge facing away from the top of the mower deck.

Clean mower deck

Mower decks packed with grass clippings, dirt and debris can damage your mower, affect cut quality and hurt lawns. Grass, dirt and debris holds moisture that corrodes bare metal on the spindles and mower blades. Additionally, grass-packed cutting decks can harbor fungi and bacteria that can spread to other lawns and damage them.

Grass buildup around the discharge area can prevent clippings from discharging evenly and could lead to clumping. Grass buildup under the deck can also affect the aerodynamics of the cutting chamber, disrupt the air lift under the deck and diminish the cut quality.

Check mower belts

While the deck is removed, inspect the mower belts for cracks, signs of wear or damage. If belts (PTO belt, mower drive belt, transaxle drive belt) appear unacceptable after a visual inspection, replace them according to the procedure in the operator’s manual. Don’t leave these to chance, because a busted belt on the jobsite will cost a lot more time than it will today.

Greasing a lawn mower

Lack of lubrication can wear critical components like bearings. Aside from applying a thin layer of oil to all pivot points and pin connections on the mower, there are typically only two or three lubrication points on a Gravely mower.

Locate the grease fittings on the caster fork hubs and the caster wheel hubs. Pump grease into each fitting until grease squeezes past the bearing seals at the top of the caster fork hubs and on the sides of the caster wheel hubs. Wipe away the excess grease.

If seat adjustment slots are visible on the bottom of the seat, apply a small amount of grease to the seat adjustment tracks and move the seat back and forth to spread grease along the tracks. All lubrication points for your mower can be found in the operator’s manual.

Charging a lawn mower battery

Mowers with discharged batteries don’t start. If the lawn mower battery was connected to a battery tender or trickle charger during storage, it should be in good shape. If the battery was left unattended, charge it to the voltage specified in the manual, but don’t fast charge the battery.

Clean battery terminals

Typically, corrosion is more likely to form on the positive battery terminal, but corrosion on any terminal should be cleaned. Disconnect the battery cables, brush away corrosion with a wire brush, coat the terminals with dielectric grease or petroleum jelly and reconnect the battery cables with the original hardware.

Zero turn mower adjustments

A zero turn mower is most comfortable and operates most effectively when adjustments are checked and returned to specification. Make comfort adjustments to the seat and steering levers for the operator that will be using the machine. Check the following items according to the directions in the operator’s manual for your unit:

- Parking brake

- Transaxle neutral position

- Tire pressures

- Deck level and pitch

Zero turn lawn mower parts

Replacement and maintenance parts like belts, blades, lubricants and oils, can be sourced from your nearest Gravely dealer. Experienced Gravely dealers know exactly what their customers and their mowers need to continue performing at their best throughout the season.

My Lawn Care Schedule. What I do, When

Don’t forget …

Smart landscapers know that during the busiest time of the season, replacement parts are in high demand at dealerships. Stay sharp this season by visiting your Gravely dealer and stocking up on a season’s supply of wear parts like belts and blades.

How to Care For and Maintain Your Lawn Mower

When your car isn’t starting up on the first turn of the key like it should, it tells you something isn’t quite right. Maybe you have a bad spark plug, maybe you’re out of gas, maybe your battery needs a charge or a change. You don’t just leave the problem undiagnosed and unresolved, though.

Yet we do that very thing when it comes to our lawn mowers. We’ll yank and yank on that starter cord until the machine barely sputters to life, and just keep doing that week after week, telling ourselves that’s just how lawn mowers are. If it’s not starting on the first couple pulls of the cord, though, something is a little off. Just as your car needs regular maintenance, so do your small engines in order to keep them running well for years and years.

Below I take you through how to care for your lawn mower to keep it working effectively and extend its lifespan. In the process, you’ll learn a little more about how it works, which is both useful and just plain interesting to know. Let’s get started.

Anatomy of a Lawn Mower

This is a rough idea of where things will be. Your lawn mower may differ slightly.

Before we get into caring for your lawn mower, you need to have a basic understanding of its anatomy. Luckily, it’s a fairly simple machine and is basically a smaller, less complicated version of a car.

In the center of your mower is the engine, along with a gas tank, oil reservoir (except for in 2-stroke mowers, which aren’t as common these days — more on that below), and air filter. At the front or side of the engine, you’ll find the spark plug. Just as in a car, the spark plug is what ignites the fuel/air mixture that makes the engine run. This is all surrounded by a metal frame (called the “deck”) which houses the blade. From there, the handlebar extends back, along with the starter cord and safety shut-off lever.

For our purposes, that’s all you’ll need to know. It’s not a bad idea, though, to go through the owner’s manual of your machine just to ensure you have a good understanding of how it operates and its various parts.

2-Stroke vs 4-Stroke Mowers

One more quick note about mower engine types before moving on to specific maintenance tasks. You either have a 2-stroke or a 4-stroke engine on your machine. As a consumer, what you need to know is that 2-stroke engines provide more oomph, while also being smaller and lighter. This would seem like an advantage. Unfortunately, they’re also louder, spew out more pollutants, and are harder to start. They’ll also keep running when tipped over (unlike the 4-stroke variety), making them more dangerous for Average Joe Homeowner. When it comes to upkeep, 2-stroke mowers use a mix of oil and gas in the same reservoir. It can be a little confusing.

For all those reasons, while 2-stroke engines are still common in commercial and large mowers, the 4-stroke has come to dominate the consumer market in the last decade. The oil-related tips below are for 4-stroke engines; if you aren’t sure what yours is, simply check for an oil dipstick/fill tub. If there is one, you have a 4-stroke mower. Your gas cap will also tell you; if it’s a 2-stroke, it will have an oil-to-fuel ratio displayed. You can also, of course, consult your owner’s manual.

Before Doing Any Maintenance, Disconnect the Spark Plug

This is a 2-second task that ensures the mower won’t accidentally start up while you’re working on it. This shouldn’t ever happen anyway with a mower made in the last 20 years; there are a number of safeguards to prevent it from starting, such as the electric shut off bar on the handle. However, it provides peace of mind knowing that the mower absolutely cannot start with the spark plug disconnected.

Clean the Deck

Clean under the deck after each mow. Always tip the mower with the air filter side up (so that liquids don’t leak into it), and brush out grass with a broom, or a gloved hand if it’s really chunked on.

Give it a more thorough clean as needed — when grass or dirt is especially caked on under the deck. Use a wire brush, soap, and water and scrub away.

Clean/Replace Air Filter

A dirty air filter burns gas less efficiently and puts more strain on the engine. Your filter is either paper (and replaceable) or foam (and cleanable). Paper ones are cheap and should be replaced annually. It’s an easy task to do while winterizing — see below for info on that. Foam filters should be cleaned 1-2 times per season.

Your air filter will be easy to find. On the opposite side of the engine from the oil cap/dipstick, there will be some sort of housing for the filter. It will open with either a latch or a screw assembly. You’ll know if you have a foam filter because it will be made of, well, foam rather than paper.

The orange part is the filter. The whole thing comes out and gets replaced.

Checking/Changing Your Mower Oil

Check your oil levels 1-2 times per mowing season. If it’s low, fill ‘er up. You check the oil just like you do your car. Twist the oil cap (usually yellow), pull the dipstick out, wipe the dipstick, and put it back in (screw it in all the way). Then pull it out once more and check the oil level and color.

It’s hard to tell in this photo, but there’s an “L” (Low) at the bottom of that textured space.

How to Maintain a Lawn Mower | This Old House

With lawn mowers, the dipsticks usually have a small textured section where the oil level should be. It should be between mid-level and full. If it’s near “Low” or “Add,” or even below it altogether, add some oil for your model (for most mowers it’s SAE-30).

Beyond the oil level, you’re also checking the color. It should be sort of a golden-brown and free of sediment rather than black and thick/chunky. If it’s black, it means your oil is mucked up for any number of reasons, and should be changed.

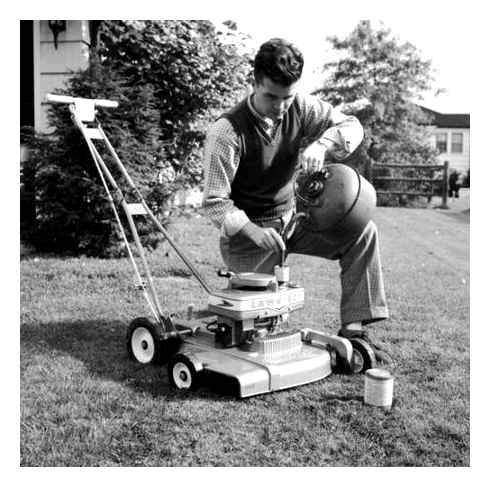

Changing Your Lawn Mower Oil

This is where your owner’s manual comes in handy. Different mowers have different oil drain plug locations (if it has a drain plug at all). It’s typically either under the deck, or below and off to the side of the dipstick (in which case the mower will need to be tipped on its side to drain).

Per my mower’s manual, you’re just supposed to tip ‘er over and let the oil drain out of the fill tube. No drain plug on my model.

If there’s no plug, you just have the tip the mower over and let it drain into a container. Once empty, fill the oil reservoir back up.

If you aren’t comfortable doing this step yourself (or simply don’t want to), many local hardware stores will do so for a pretty reasonable price.

Winterize Your Mower

With just a few easy steps, you can ensure hassle-free startup in the spring so that you aren’t left hanging with extra long grass because your mower is in the shop.

Empty the gas tank. A non-starting mower in the spring is most often the effect of gas being left in the tank without use over the course of many months. One repairman I talked with said that after not being in use, gas basically turns to varnish and mucks up the engine. You have two options for emptying the tank: run it until it’s dead (tie down the shut-off bar so you don’t have to hold it), or siphon it out into a container. If you have a lot of gas left, siphoning is the best bet so as to not waste the fuel. When done simply put the gas into your car’s tank (if it’s not mixed with oil), or dispose of it based on your locale’s hazardous waste guidelines. After siphoning, start the mower and let it run until it dies; there’s likely some fuel left in the lines which could gum things up over the cold season.

Disconnect the spark plug and give it a clean. Did you see all the dirt that was caked on the spark plug in the GIF above? Wipe it all clean.

Remove the blade for sharpening, and possibly oil drainage. Rocks, branches, mulch, and natural dulling happens over the course of a mowing season. You can sharpen your own blade with a certain amount of know-how, but my local Ace Hardware will do it for 7 at the beginning of the season, which is darn worth it to me!

Simply tip your mower (air filter up, remember) and use a socket wrench to take the blade off. It allows access to your oil plug — if your mower has one — and also makes it easy to get sharpened. If you’re sharpening yourself, you need it removed anyway. And if you’re having a hardware store do it, better to bring in just the blade versus the whole darn machine.

Drain and replace the oil. Use the instructions above.

Replace Spark Plug as Needed

Some folks recommend changing the spark plug annually since it’s a cheap and easy piece of maintenance, but unless your mower is starting a little slowly, there’s no need to change it. Every 2-3 years is perfectly fine, and even longer if your mower is starting without a problem.

You’ll need a special wrench to remove and replace the plug. Don’t worry, you can get one for under 10. This is another task that you could have a hardware store do with a mower tune up, but it’s a good thing to know, and sometimes just satisfying to do yourself.

To do it yourself, disconnect the plug, and use your special spark plug wrench as you would a socket wrench. As you can see in the close-up image above, the spark plug is basically a large hex bolt. If the plug doesn’t move at all, lubricate it well, then try again.

The lawn mower is a real utility tool, and not very “sexy,” but, like every tool, it needs regular care and maintenance to keep it performing optimally. Follow the tips above, and your mower can make your lawn look like Wrigley Field, and last for many years to come.

Lawn Garden

Lawn mowers are commonly used tools by both homeowners and landscapers. Whether a landscaping professional or a weekend warrior, performing routine maintenance on a lawn mower is important to keep it running smoothly and to extend the life of the machine.

Routine Mower Care

There may come a time when a lawn mower will have to be replaced. However, the following 10 routine maintenance steps will help extend the life of the mower. Taking these steps will also help owners avoid more expensive lawn mower repair projects in the future.

Step 1. Stabilize the Fuel

Fuel that sits in a mower for a long period of time can clog a carburetor. Operating a lawn mower often during the mowing season will prevent this from happening. However, if a mower goes more than 30 days at a time without being used, a fuel stabilizer needs to be added. A fuel stabilizer costs less than ten dollars at a local lawn and garden store. Adding a fuel stabilizer when preparing the mowing for storage in the off season, is also recommended. If not done, when mowing season starts again in the spring, people may have to pay to have the carburetor professionally cleaned.

Step 2. Change the Oil

Changing the oil in a lawn mower extends the life of the engine. The moving parts inside the engine undergo friction, which causes heat. Eventually, this heat causes parts to breakdown, so those parts must be lubricated with oil. Be sure to refill the oil reservoir to the designated mark on the dipstick. Remember too much oil can be just as bad for the engine as too little oil. Using a high grade oil will improve engine operation, lubrication, and fuel economy.

Step 3. Get a Reliable Battery

A freshly charged battery can improve the efficiency of lawn equipment. A mower needs a certain amount of voltage to power its lights, sensors, blades, starter, and coil.

Step 4. Keep the Deck Clean

Keep the area beneath the mower deck free of grass clippings to reduce rust buildup. Using water is good, but always remember to wipe the deck off after rinsing the mower. Use a blower or a bristled scrubber to remove buildup on hard-to-reach surfaces. Some people use a silicone spray to prevent future buildup on and under the deck.

Step 5. Replace the Spark Plugs

Spark plugs play a critical role in any engine as it relates to fuel combustion. An engine will not start without the proper amount of electricity from the spark plug. A spark plug needs replacing every 100 hours. If an engine runs roughly, there is a good chance that it might need replacing. Always check the owner’s manual for specifics on replacing spark plugs. The price of one spark plug can range from five to ten dollars, depending on the size of the equipment.

Step 6. Sharpen the Blades

Mower blades are critical when it comes to cutting grass. Remember to keep blades sharpened and balanced. When a mower has dull blades, the motor requires additional power to turn the blades. At that point the blades are not making a smooth cut. They tear off the end of the grass, causing the grass to cast a white appearance over a yard for a few days.

People should sharpen their blades often if they have fast-growing grass that requires frequent mowing. It is also wise to keep an extra set of blades available just in case they are needed. The cost of the blades is around thirty dollars, depending on the size of the equipment. For safety reasons, only use blades that are recommended for that particular model of lawn mower by the manufacturer.

Step 7. Check the Air Filter

Cleaning the air filter allows the engine to receive the proper amount of air it needs to get the optimal fuel to air ratio for successful combustion within the engine. As a mower cuts grass, small dust particles and grass clipping are attached to the air filter, along with the air that is needed for the engine to run. Clean the filter with a mild detergent or, if the filter is too worn to clean, replace it with a new one. Revisit the service manual to determine the recommended intervals for cleaning and replacement. The cost of an air filter is less than ten dollars, depending on the size of the equipment.

Step 8. Replace the Fuel Filter

Clean fuel is essential when it comes an engine running smoothly and efficiently. The fuel filter cleans all of the fuel that comes from the fuel tank to the engine. Particles from a gas container may fall in the fuel tank of the equipment. The filter will clean the fuel as it passes through, resulting in a much easier process of fuel delivery.

Smaller lawn equipment usually does not carry a fuel filter, but large- to medium-sized equipment typically comes with one to help with the filtration of the fuel. Regularly check and replace the fuel bulb primer on smaller equipment. Review the service manual to determine recommended intervals for cleaning and replacing filters and primer bulbs.

Step 9. Check Tire Pressure

Believe it or not, proper tire pressure can affect how level the grass is cut. If the tire pressure on a mower is low on one or more tires, it will make the deck cut the grass unevenly. Proper tire pressure makes the difference between a good ride on a mower or a bumpy one. Furthermore, pushing and pulling the unnecessary weight of flat tires will cause friction to be placed on the engine and transmission. Routinely check the air pressure and the condition of the tires.

Step 10. Service the Belts

Check for cracks and worn spots in the belts to eliminate any breakage and improper turning with the pulleys. If the equipment is used to cut a hill and the belts are worn, it will not have the power it needs to operate at full capacity. Also, belts function to turn the pulleys with the blades attached. If the belts are old with cracks, the equipment will not have the full power to cut the grass with ease.

Maintain Mower Care

Carefully follow all manufacturers’ instructions for routine repair in the lawn mower service manual. Following the service manual and these ten steps will help maintain a lawn mower for years to come. Visit the Alabama Extension Urban Lawn and Garden page for more information on urban landscaping.

Extend the lifespan of your lawn mower with these minor repair and regular maintenance tips.

By Timothy Dale | Updated Aug 16, 2021 11:14 PM

We may earn revenue from the products available on this page and participate in affiliate programs.

A lawn is a great place for kids to play, pets to run, and adults to host family and friends, but the grass must be regularly cut in order to ensure that it grows healthy and doesn’t become overgrown. Overgrown lawns can often attract harmful pests like ticks, which are known to live in grass that is more than 4 inches in tall. So, it’s important to make sure that you can keep a healthy trimmed lawn by performing minor repairs and ongoing maintenance on your lawn mower.

While some issues are better dealt with by professionals, lawn mower repair and maintenance isn’t necessarily complicated. By establishing and adhering to a maintenance schedule, most issues can be resolved with minor inspections and repairs, including simple tasks like sharpening the blade, using the appropriate fuel, replacing the oil, or changing the air filter. Continue reading for tips on what to do and what not to do in order to properly repair and maintain a lawn mower.

DO sharpen the blade.

This may seem like an obvious task to some, but others may use their lawn mower season after season without paying any attention to the blades. Not only should the blades be regularly inspected for warping, rusting, and other damage, but they also need to be sharpened about twice per season or every 25 hours of use to help extend the life of the blades and the mower.

Sharp blades don’t just help the mower cut the grass better, they also make clean cuts through the grass, which reduces the likelihood of the lawn developing a disease. Inspect the mower blade for dents or nicks, and take note if the grass height is uneven after cutting, the edges of the grass look brown, or if the grass blades are torn instead of sliced clean through. Each of these signs is a symptom of dull blades that need to be sharpened.

DON’T choose a fuel with an octane rating lower than 87.

As with any gas-powered machine, the type of gas that is used can impact the grass-cutting ability of the mower and the longevity of the engine. Gas is rated based on the amount of filler that is included in the gasoline formula, so octane 91 gas, which is often referred to as premium, has less filler than octane 87 gas that is called regular.

The minimum octane level that lawn mower gas should have is 87. This ensures that the gasoline meets the requirements for use in standard motor vehicles, reducing the chance that the engine will be damaged while burning the gas.

Some users may prefer to fill their lawn mowers with premium-grade gasoline, though this isn’t typically required. The best gas for your mower is the type that is suggested by the owner’s manual. However, switching to a premium grade gas during cooler weather, like early spring and late fall, is a good idea to help maintain the health of the engine.

DO check the spark plugs every two months.

Spark plugs in a lawn mower serve the same purpose as they do in a car or truck. These little parts of the engine serve as an ignition source for the gasoline. When they start to fail, it becomes immediately obvious. It’s important to inspect the spark plugs about every 2 months during regular use.

Signs that the spark plug on the mower may be failing include hard starts, poor engine performance, unreasonable fuel consumption, and a worn, cracked, or chipped physical appearance of the spark plug. If the engine is difficult to start up or it tends to die out immediately after the engine finally does start, then the issue may be the spark plug.

DON’T neglect cleaning the deck.

It’s never a bad idea to clean the deck of a lawn mower. Some people say to clean the deck once a month, others insist that it be cleaned after each use. It’s helpful to check the underside of the mower after every use to remove any stuck-on grass, dirt, weeds, or other debris. While keeping the deck clean will reduce the chance that the lawn mower will begin to rust or corrode from the inside, this isn’t the only reason to clean it.

As the deck of the lawn mower slowly fills with grass clippings, weeds, and dirt, the accumulation creates a barrier that prevents the grass from standing up straight while underneath the mower. This results in a poorly cut lawn and this build-up can even start to hinder the rotation of the blades, putting undue stress on the engine, blades, and component parts of the mower. So, after mowing the lawn, just take 5 minutes to flip the machine over and clean out the deck, saving the hassle of future lawn mower repairs.

DO inspect the flywheel.

A flywheel is a part within the engine of the lawn mower that stores the momentum from the combustion process in order to keep the crankshaft turning between the power strokes of the engine. It also helps cool the engine by blowing air around the engine block. Without a functional flywheel, the engine could quickly become overheated or it may not even start.

Some signs that a flywheel is damaged or failing include the inability to start the engine, the engine constantly stalling, and a burning odor from the engine. It’s advised to inspect the flywheel at the beginning and end of every lawn maintenance season to check for cracks, broken fins, slight burrs, shearing, and crankshaft damage. Just make sure to disconnect the spark plug lead before opening the engine to check the flywheel.

DON’T neglect oil changes.

Similar to sharpening the lawn mower blades, changing the oil in the lawn mower is a task that can either be almost entirely ignored or regularly performed with strict adherence to a maintenance schedule, depending on the user. If you don’t know exactly how it benefits the lawn mower, then it may seem like changing the oil does a lot. However, without this lubrication on the moving parts of the mower, the engine begins to seize and break down prematurely. Many people think of oil as the lifeblood of the engine, so it makes sense that the engine cannot function without it.

Check the oil level with the lawn mower dipstick before each use and change the oil when it becomes murky. For regular maintenance throughout the year, it’s advised to change the oil about once every 25 hours of use or at least twice per mowing season to ensure that the lawn mower engine is properly lubricated with clean oil.

DO change the air filter.

The air filter in the lawn mower is designed to protect the engine by trapping dust, dirt, and other debris, but the filter can only hold so much dirt and debris before it becomes dirty and clogged. Some lawn mowers have reusable air filters that can be removed and washed, but this is a rare feature. Generally, a lawn mower filter should be replaced about once every year to help maintain a healthy engine.

Symptoms of a dirty or clogged air filter include a dirty physical appearance, engine misfires, a reduction in the horsepower or power output of the engine, concerning engine noises, strong fuel smells, and in serious situations, flames or black smoke can be produced by the engine. If you detect any of these signs, stop mowing and go get a replacement air filter. They are inexpensive and relatively easy to replace if you follow the lawn mower manufacturer’s guidelines for air filter replacement.