Seeder for a tiller do it yourself

The device and principle of operation of potato planters for tiller

Such devices consist of:

- frames;

- a bunker in which potatoes are laid, intended for planting;

- wheel base;

- mechanism that provides loosening of the soil and planting tubers on the site.

Most models have a similar device

Attention! In addition to those listed, other elements may be present. for example, a container for fertilizer.

The principle of operation of such a device is very simple. The sprocket mounted on a wheel base is part of the chain elevator. When the wheels rotate, the tubers from the hopper rise along a vertical pipe, and then are dumped down into the prepared furrow.

The planting process is simple enough

Tool selection specialist “VseInstrumenty.ru”

“This design of the potato planter implies planting in a pre-cut furrow. At the same time, powerful tillers or mini tractors can prepare a planting site and plant tubers. “

Device with fertilizer hopper

Spread drills

Devices of this type have a simple and reliable design, do not require special maintenance and rarely need repair. The principle of operation of the spreader drills on the tiller is very simple: during operation, the seeds picked up by a special disc are subject to pressure, as a result of which they are thrown out of the seeder onto the site.

The advantages of such devices include high performance. Among the disadvantages should be highlighted the difficulties when using seeders at the edge of the site, in which most of the seeds are thrown out of the garden.

Nest seeders

Adaptations of this kind are best suited in cases where the farmer needs to sow crops exactly in the wells or nests prepared in advance. Tiller nest drills can be successfully used for sowing seeds of garlic, onions and other small planting material.

The advantages of nesting seeders for the tiller include ease of use. Such equipment is small in size and weight. However, seeders of this kind are very slow and therefore take a long time to work with.

Seed drills

Such attachments are used for drill seeding and simultaneous planting of seeds in the soil. Depending on the purpose, there is an ordinary seeder for a tiller for garlic, a corn seeder for a tiller and a universal seeder that is suitable for sowing seeds of any crop.

The main elements of tiller drills are openers and seeding devices. The coulters are equipped with special “legs” or chains, which are necessary for planting seeds in the ground. In order to operate in areas with heavy soils, seed drills with disc openers are used, and for use on loose soil, attachments with anchor openers are used. The main advantages of seed drills are uniformity of sowing and optimal planting depth of planting material.

Homemade seeder for tiller: manufacturing features

In order to obtain a truly practical device upon completion of all the necessary procedures, you must:

- Two running wheels;

- Seed box;

- Screws and nails;

- Steel sheets;

- Rubber plates;

- Sowing roller;

- Self-tapping screws, spikes, steel corners;

- Two bearings and brackets.

The process itself is simple, but requires maximum concentration, so you need to pay attention to the following features:

- A seed box can be crafted from planks (wood) (no more than 15 mm thick);

- To close them from the bottom side, you can use steel overhead bottoms (1 mm thick);

- The walls themselves are connected using self-tapping screws, iron corners and spikes;

- From the bottom of the walls of the box, thanks to nails, wooden lining is mounted (15 mm thick);

- The process of placing the seeding roller in the walls and linings is accompanied by the creation of cutouts (semicircular shape). Using screws, carefully screw the mounting brackets to the linings;

- Special rubber plates, which are placed in the inclined bottoms, facilitate the loss of seeds from the cells;

- Wheels of the created grain seeder for tiller (or corn) have hubs of 60 mm;

- Special holes are created in the hubs (the diameter is similar to the seeding roller);

- The opener can be made from a sheet of iron and then attached to the brackets;

- You can adjust the depth to which the seeds will be placed by re-securing the opener in the special holes;

- On the rear wall of the seed box, a bracket can be adapted to serve as a “connecting link” between the device and the tiller.

Varieties and descriptions of seeders for tiller

Tiller planting of garlic and other crops can be done with different planters. Below we will consider the design features of each of the types of seeders for a tiller in more detail.

Seeder to tiller. the principle of operation of the device

The tiller garlic planter works in a very simple way. The main structural elements include the chain drive and rear wheel, which function as a single unit. The transmission acts on the wheel and sets it in motion, as a result of which the seeds fall to the ground. All planting material is contained in a special hopper, previously designed for sowing simultaneously in all rows.

In modern planters, you can adjust the sowing rate of the seeds and the size of their bulbs. This also gives the farmer the opportunity to increase or decrease the number of plantings. Different models of seeders allow you to adjust the seeding depth, which usually varies from zero to a few centimeters.

In cases where carrot seeds or other small planting material are to be planted, the farmer can use fillers. As them, you can use various cereals or bran. However, river sand cannot be used for this purpose, as it can damage fragile seeds.

Homemade seeder

Homemade seeder

Seeder for tiller. this is one of those attachment tools that is essential for full agricultural work. Agree, I want to give the most complex and lengthy processes and work in the field to specialized machines. The tiller seeder has been very popular for decades. We offer you to make a homemade seeder.

Planting the harvest. a very complex and routine process that is difficult to carry out, even with a small area. Needless to say about working in the fields and large farm areas. That is why tiller seeders are very popular all over the world, including in our country. The seeder itself has a fairly simple operating principle. Its main nodes. it is a rear wheel and a chain drive, which are a single, harmoniously working mechanism. By driving the rear wheel in motion, the chain drive allows the seeds to fall out into the prepared soil.

The seeding speed of the planting material is preliminarily regulated. You can also set the estimated sizes of sown bulbs and seeds in advance.

Rather stringent agrotechnical requirements are put forward for modern seeders. The device must be designed in such a way as to take strictly one seed from the hopper and, without damaging it, bring it to the soil. Today there is a huge variety of tiller drills, from single row to eight row. However, let’s talk about how to construct a homemade seeder.

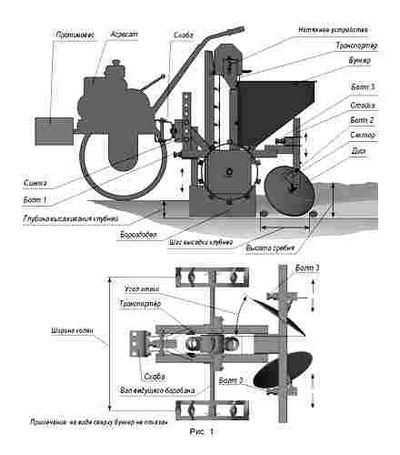

Let’s take a look at how to make a two-row homemade seeder.

Such a device should consist of two independent sections, each of which will have:

The reinforcement on the section frame must be movable so that it is possible to control the row spacing and vary it from 15 to 70 cm. The running wheel of a homemade seeder will drive the working bodies of the reel-type seeding apparatus. In order to orient the sowing, a double-sided marker should be installed.

The frame of a homemade seeder is made from corners of 4040700 mm, and the hopper for planting material is made of boards. Its optimal dimensions. 240 210 700 mm. From an old grain seeder, it will be convenient to use a reel-type seeder. And for the support wheels, the old sprockets of the combine are perfect. The hanger brace can be easily made from 630 strip steel 800 mm long. Please note that the support for the seed hopper, the support for the seeding machine shaft, roller brackets, openers, fastening chains, square and various other necessary parts should be made in the workshop. It doesn’t take much time and effort. Perhaps some of these details can be found on your farm.

Below is a diagram of the manufacture of a homemade seeder.

Making a seeder with your own hands. an uncomplicated and rather exciting process. Here it is only important to observe the proportions and fulfill the basic requirements for the dimensions of materials and their comparison with each other.

On our website you can also read about the homemade production of other attachments for the tiller, for example, lugs, creepers, mowers, potato diggers, potato planters, plows, etc.

Generally speaking, making tools for a tiller with your own hands. this is a very interesting process. Using all kinds of old, obsolete components, assemblies, tools and devices, you can create new useful units that will help you in housekeeping. Drawings, which we often attach to our articles, will help you to facilitate work, save time and effort. Create with pleasure.

1 How the tiller seeder works

The chain drive in conjunction with the rear wheel is a single unit and the main mechanism of operation. The seed hopper is designed for simultaneous sowing in two to five rows of beds; large-sized or modular seeders have their own hopper for each row. Small seeds such as carrots are mixed with filler. Bran or boiled cereals are suitable for this, but in no case should sand be mixed, which damages the seeds.

Vegetable precision planters use a brush to loosen the seeds. During the operation of the support-drive wheels, the brush rotates and agitates the seeds so that they evenly pour out into the hole in the rear wall of the hopper. The outlet from the hopper is closed by a rotary disc with different diameters of through holes to regulate the size of the planted seeds. Or, with its help, 2-3 grains are planted at the same time.

Seeder to tiller

The planting speed, the number of seeds planted at a time and the planting depth are adjusted in advance. Another plus of this agricultural equipment is that it can be installed on different types of tillers, light, heavy, automatic, manual.

to the menu

Tiller Box Precision Planter. Complex Assembly Method

As in the first case, before starting work, study the detailed diagram that will help prevent assembly errors. A seed drill should be composed of several basic elements. You will need:

- 2 wheels for moving around the site;

- seed hopper;

- seeding roller;

- 2 bearings;

- handle with bracket;

- 2 brackets required to mount the opener.

The manufacturing procedure is as follows:

- You can make the bunker from wooden planks, approximately 1.5 cm thick. For the bottom of the bunker, use several bushes of sheet steel, welded to each other. Connect the sides of the box along and across with self-tapping screws, steel corners or spikes. At the bottom of the walls of the hopper, install wooden strips, 1.5 cm thick. Use nails or screws to secure them. At the rear of the seed drill hopper, fix the bracket, by means of which the device will be connected to the tiller;

- To mount the seeding roller in the walls and linings, cut the cutouts in the shape of a semicircle. Next, attach the fixing brackets to the linings with screws. So that when sowing the seeds fall exactly to the intended places, install several rubber plates in the inclined bottoms;

- The seeder wheels must have a diameter of at least 20 cm. To fix them, use hubs, 6 cm long. Make holes in the hubs that should be the same size as the holes in the seeding roller;

- Use 1.5 mm thick sheet steel to make the opener. Next, attach the element using brackets. Make several holes in one of the brackets. you will need them to adjust the depth to which the seeds will be sown. To set this parameter, you will need to move the opener from one hole to another.

A seeder made in this way will help to quickly plant seeds of garlic, onions, corn and legumes. In this case, the seed will fall exactly into the pre-prepared holes.

Homemade seeder for tiller. DIY options

There are several ways to make a seeder to the tiller. When choosing a method, be sure to consider your capabilities and experience with the equipment. Next, we will consider each of the methods in more detail.

Premium STV-2

The two-row motoblock seeder of the “Premium” series. CTB-2 is designed for the introduction of seeds of corn, garlic and other vegetable and grain crops, of various fractions, into the soil on pre-prepared areas. This model makes simultaneous furrowing, seed placement and incorporation into the soil, as well as compaction of rows. The seeder can be installed on tillers with a capacity of 6 hp and more.

Precision seeding seeders overview. operating principle, types and price analysis

Tiller mounted seeder

One of the types of such attachments is a tiller seeder. Such a seeder makes it possible to sow the majority of vegetables and grain crops quite easily, quickly, efficiently and with minimal energy consumption. Such equipment is an irreplaceable assistant in small agro-technical farms. However, when choosing a planter, you need to make sure that it can be fitted to your tiller.

A seeder on a tiller. an easy way to make

Be sure to study the drawings immediately before making a simple tiller planter. They will tell you the dimensions of the parts, the method of fastening them and the correct procedure for assembly. Next, you should prepare materials and tools. To work you will need:

- steel sheets, no more than 5 mm thick;

- 3 metal discs;

- steel pipe;

- wooden block;

- bicycle chain;

- 3 small wheels;

- bolts and screws;

- welding machine;

- hacksaw for metal;

- electric drill drill;

- multi-sheet plywood.

Got Rid Of Made In Germany Seeder. Got Eastern European Instead

The manufacturing algorithm is as follows:

- First, weld the U-shaped planter frame as shown in the diagram. To make it, take sheet metal, 52.5 cm long and 11.5 cm wide;

- At the top of the frame, place the seed hopper in the form of a box, which can be made from plywood;

- Place the seed meter inside the hopper, which must be mounted on two plain bearings. The machine itself should have the shape of a shaft and resemble a spool for winding thread. It can be made from a piece of wood and varnished;

- Then take a steel pipe, which will serve as an axis, and put 3 metal discs on it, which should be fixed at the same distance from each other;

- In the rim of one of the discs, drill 12 holes into which the seeds will fall. When the drill starts to work, this disc with holes made in it will fall into the hopper with planting material. The captured seed will then fall into the furrows set directly in front of the drill discs. To rotate the disc, put on a bicycle chain, the other end of which is attached to the rotor of the tiller engine;

- Next, at the rear of the planter frame, weld a horizontal piece of steel sheet, which is necessary for planting seeds in the soil;

- After that, 3 wheels must be attached to the bottom of the structure. The front wheel can be taken from an old stroller, and the two rear wheels can be taken from a child’s bike. The video will tell you in more detail about the manufacture of a simple seed drill.

A DIY seed drill is equally well suited for sowing garlic or corn seeds. In the process of moving the device over the previously plowed area, the seeder coil begins to rotate, which occurs due to the presence of a bicycle chain. The seeds that are in the hopper are scooped up by the cells of the coil, after which they move into the funnel of the seed tube, and from there into the ground.

Dotted planters

These attachments are used for sowing seeds of garlic, onions, corn and legumes in pre-prepared nests, which are located at a certain distance from each other. Despite the complex design and large dimensions, the dotted seeders to the tiller are quite easy to operate.

The advantages of such attachments include high sowing accuracy and good productivity. Among the disadvantages should be highlighted the inability to use such seeders in areas with heavy clay soil.

1.3 Seeder for garlic tiller

If you want to plant garlic, onions, tulips and similar plants, which are sown with heads and bulbs, then equipment designed for vegetable crops is used. For garlic, the CTB series, small-sized SV-6 are suitable, and for large areas. vacuum SVTV 4-8.

Seeder for garlic and onion. as well as any seeds, tubers and bulbs

There are specialized seeders designed primarily for heads of garlic. At these from the common bunker, with special spoons, like dredge buckets, garlic bulbs cling to and directed into a previously created furrow. Some do not have digging plates and wheels for compacting the soil, they can be adjusted by yourself.

to the menu

Seeder for a tiller: principle of operation, do-it-yourself manufacturing

A modern seeder on a tiller is a device that allows you to plant seeds of garlic, onions, corn and other crops, saving the farmer’s energy and time. The design of the seeder is simple enough that you can make it yourself.

What is required for this, and how to make equipment with your own hands. let’s talk in more detail.

Dotted planters

These attachments are used for sowing seeds of garlic, onions, corn and legumes in pre-prepared nests, which are located at a certain distance from each other. Despite the complex design and large dimensions, the dotted seeders to the tiller are quite easy to operate.

The advantages of such attachments include high sowing accuracy and good productivity. Among the disadvantages should be highlighted the inability to use such seeders in areas with heavy clay soil.

Varieties and descriptions of seeders for tiller

Tiller planting of garlic and other crops can be done with different planters. Below we will consider the design features of each of the types of seeders for a tiller in more detail.

Nest seeders

Adaptations of this kind are best suited in cases where the farmer needs to sow crops exactly in the wells or nests prepared in advance. Tiller nest drills can be successfully used for sowing seeds of garlic, onions and other small planting material.

The advantages of nesting seeders for the tiller include ease of use. Such equipment is small in size and weight. However, seeders of this kind are very slow and therefore take a long time to work with.

Spread drills

Devices of this type have a simple and reliable design, do not require special maintenance and rarely need repair. The principle of operation of the spreader drills on the tiller is very simple: during operation, the seeds picked up by a special disc are subject to pressure, as a result of which they are thrown out of the seeder onto the site.

The advantages of such devices include high performance. Among the disadvantages should be highlighted the difficulties when using seeders at the edge of the site, in which most of the seeds are thrown out of the garden.

Homemade seeder for tiller. DIY options

There are several ways to make a seeder to the tiller. When choosing a method, be sure to consider your capabilities and experience with the equipment. Next, we will consider each of the methods in more detail.

Seed drills

Such attachments are used for drill seeding and simultaneous planting of seeds in the soil. Depending on the purpose, there is an ordinary seeder for a tiller for garlic, a corn seeder for a tiller and a universal seeder that is suitable for sowing seeds of any crop.

The main elements of tiller drills are openers and seeding devices. The coulters are equipped with special “legs” or chains, which are necessary for planting seeds in the ground. In order to operate in areas with heavy soils, seed drills with disc openers are used, and for use on loose soil, attachments with anchor openers are used. The main advantages of seed drills are uniformity of sowing and optimal planting depth of planting material.

Seeders for tilers: types and how to do it yourself

tillers are reliable assistants in agricultural and land work, and their productivity is significantly increased thanks to specialized types of additional equipment.

Tiller planters help to plant multiple crops evenly, achieving the desired grain density.

Today, many companies offer absolutely various types of these devices for purchase, so it is important to familiarize yourself with the types and choose the most profitable option for your device. over, you should not exclude the possibility of creating a seeder with your own hands, which, oddly enough, with a competent approach, the presence of parts and drawings is an easy task.

2 Seeder for a tiller do it yourself

The basis of any motoblock seeder, the bunker, is made of wooden planks or plywood. The metal will add unnecessary weight and bulkiness. Inside, a vertical brush wheel is installed to the size of the hopper, driven by a shaft connected by a chain (for example, a bicycle chain) to the front wheel.

At the back of the hopper, there is a hole closed by a wheel with seed nests of suitable size for the grain. It can be twisted to adjust the seeding speed and the size of the planting material. Through this wheel, the seeds enter the furrows mounted at the rear of the drill. A metal plate is installed at the bottom of the frame, digging a trench of the required depth in the soil. The seed burial plate is placed perpendicularly, and the rear wheel is used as a tamping roller.

Frame on the front wheel in the shape of the letter “U” with a hole for fastening several drills in one row. The frame is made of sheet metal. The seeder adapts to the Varyag tiller using a universal coupling, which allows using various types of seeders.

to the menu

seeder for tiller

1.3 Seeder for garlic tiller

If you want to plant garlic, onions, tulips and similar plants, which are sown with heads and bulbs, then equipment designed for vegetable crops is used. For garlic, the CTB series, small-sized SV-6 are suitable, and for large areas. vacuum SVTV 4-8.

Seeder for garlic and onion. as well as any seeds, tubers and bulbs

There are specialized seeders designed primarily for heads of garlic. At these from the common bunker, with special spoons, like dredge buckets, garlic bulbs cling to and directed into a previously created furrow. Some do not have digging plates and wheels for compacting the soil, they can be adjusted by yourself.

to the menu

What are the seeders

Regardless of whether a factory seeder or a home-made seeder, they are all classified according to the method of seeding and by the principle of operation. According to the method of sowing, they are:

- nesting;

- privates;

- dotted;

- scattering;

- square-nested.

According to the principle of work, they are distinguished: universal and highly specialized, intended for sowing one crop or one group of crops. grain, corn, etc. For work on personal plots, it is preferable to use universal models that are capable of sowing seeds of both cereals and vegetables into the soil. Farmers, on the other hand, prefer to use highly specialized units that correspond to the specialization of their activities.

But, both for farmers and for private households, the accuracy of sowing seeds is of great importance. Therefore, the most demanded in recent years has become the most economical of seeders. dotted or, as it is more often called, a precision seeder.

Homemade seeder for tiller: manufacturing features

In order to obtain a truly practical device upon completion of all the necessary procedures, you must:

- Two running wheels;

- Seed box;

- Screws and nails;

- Steel sheets;

- Rubber plates;

- Sowing roller;

- Self-tapping screws, spikes, steel corners;

- Two bearings and brackets.

The process itself is simple, but requires maximum concentration, so you need to pay attention to the following features:

- A seed box can be crafted from planks (wood) (no more than 15 mm thick);

- To close them from the bottom side, you can use steel overhead bottoms (1 mm thick);

- The walls themselves are connected using self-tapping screws, iron corners and spikes;

- From the bottom of the walls of the box, thanks to nails, wooden lining is mounted (15 mm thick);

- The process of placing the seeding roller in the walls and linings is accompanied by the creation of cutouts (semicircular shape). Using screws, carefully screw the mounting brackets to the linings;

- Special rubber plates, which are placed in the inclined bottoms, facilitate the loss of seeds from the cells;

- Wheels of the created grain seeder for tiller (or corn) have hubs of 60 mm;

- Special holes are created in the hubs (the diameter is similar to the seeding roller);

- The opener can be made from a sheet of iron and then attached to the brackets;

- You can adjust the depth to which the seeds will be placed by re-securing the opener in the special holes;

- On the rear wall of the seed box, a bracket can be adapted to serve as a “connecting link” between the device and the tiller.

If a person really set himself the goal of creating an excellent “helper” with his own hands, then the described features, steps, drawings and videos posted on our website will contribute to obtaining the desired result!

2.1 The device of the seeder mounted on the tiller Rosta SR-4

Types of modern tiller drills

Seeders are used to distribute seeds evenly in the ground. Additional functions include soil wetting, fertilization, and insecticide addition. The seeder for the tiller is the same design as for the tractors, only in a reduced version.

However, the functionality is retained. Therefore, for small farms, summer cottages, a compact seeder for a tiller is suitable.

How to make a seeder for a tiller with your own hands?

In order for a homemade seeder for an existing tiller to be balanced and multifunctional, you should strictly adhere to a certain scheme. The drawings used should promptly suggest the dimensions of the parts and how to install them in the overall structure.

After studying the drawings, you should proceed directly to the assembly of equipment with your own hands:

- First you need to make a frame. It can be made from pipes or iron strips welded to each other in the shape of the letter P;

- A hopper should be installed on top of the frame and bolted;

- Inside the hopper, you need to place a seeding mechanism, which will need to be installed on 2 sliding bearings;

- Next, you need to take a pipe, which will play the role of an axis, and put 3 undamaged discs on it. The latter must be installed at the same distance;

- Further, in each of the discs, 12 holes must be drilled into which the planted seeds will be placed. During the movement of the seeder, the disks will pass through the hopper, and the seeds will fall into the holes, after which the disks will direct them into the furrows preset opposite the disks;

- At the back of the frame made, a special bar should be installed, which will embed seeds into the soil;

- From the bottom, you need to attach 3 wheels to the frame. details about the assembly of the seeder for the tiller will be described in the video.

In the process of using a homemade seeder, the seeding wheel will rotate under the action of the bicycle chain. This will cause the perforated discs to move. In this case, the seeds, after falling into the holes made earlier, will be transported into the furrows, after which they will begin to fall into the ground. At the same time, the bar at the back will embed the seed into the soil.

How the seeder works on a tiller?

The chain transmission of the seeder paired with the rear wheel provided in its design is the most important working mechanism of the equipment. The seed drill hopper is preliminarily designed for simultaneous sowing in an area with a width of two to five rows made. Larger planters or modular implements have a separate hopper for each row. When sowing, small seeds, such as carrot seeds, should be mixed with fillers in the form of bran or boiled cereals. However, the seeds should not be mixed with sand, as it will only damage the structure of delicate seeds.

Each vegetable seeder is pre-equipped with a brush for loosening the planted seeds. In the process of rotation of the support-drive wheels, the brush is driven, which agitates the seeds. This allows the seeds to flow more evenly into the hole in the rear of the existing seed drill hopper. The outlet in the hopper is closed with a special rotary disc, which can have different diameters. The size of the outlet can also be different. this allows you to sow seeds of different cultivated plants, as well as plant several seeds at the same time.

The drill is designed to preset the sowing depth and speed, as well as the number of seeds to be planted. Another great advantage. the seeder can be used with any tiller, regardless of its class.

Types and features of seeders for tillers

Depending on the type of seed intended for sowing, seeders for tillers are divided into several types. Such a classification is necessary, first of all, so that the buyer can determine the most suitable equipment for his needs.

Seeder grain for tiller

Tiller grain drills are equipped with small bins located in the center of the structure. If necessary, such a seeder can be equipped with additional containers for grain.

Equipment of this type is made of tough alloys with increased corrosion resistance.

Seeders for tiller

A seeder is a type of attachment designed for planting crop seeds. Its presence and active use allows sowing large areas, saving a lot of time and effort for the farmer.

Tiller bean seeder

This kind of device has wide non-adjustable inlet and outlet openings, as well as a spacious hopper.

The main advantages of seeders for leguminous crops are endurance and long periods of practical use.

Seeder maize for tiller

This fixture has large and usually non-adjustable inlets and outlets. Among the advantages of such seeders, experts point out an excellent balance, which makes this equipment more stable on uneven surfaces.

Among the main advantages of such seeders, experts emphasize ease of use and compactness.

Seeder for garlic tiller

This type of equipment allows sowing seeds of garlic and other crops whose seeds are medium in size. The garlic planter for the tiller has diameter-adjustable inlet and outlet openings, which makes it possible to use such a device directly for sowing a number of other agricultural plants.

The main advantages of this kind of household appliances include durability, wide functionality and the ability to adjust for work in specific conditions.

Seeders classification for tiller

A seeder for a tiller is an additional device that can be aggregated onto a cultivator and allows you to accurately distribute the planting material along a given route. Functionally, it fully corresponds to its large-sized analogue. a tractor seeder, which is several times larger than it.

Motoblock seeders differ in:

- universal. adapted for planting seeds of various crops. This category includes most grain or grain-grass seeders, which, in addition to cereals, do an excellent job of planting oilseeds, legumes, small-seeded, etc.;

- special. customized for one or more plant species. Therefore, they are presented in the following options:

- tiller corn seeders;

- vegetable;

- cotton;

- garlic;

- beetroot.

Depending on the scheme of planting the seeder on the tiller, there are:

- ordinary. designed for planting seeds or tubers in formed rows. According to the method of implementation, there are:

- privates;

- narrow-row;

- wide-row;

- tape.

In terms of the number of rows covered, tiller seeders are most often found in 6-8 rows, which successfully compete with the most primitive one- and two-row assistants. Unlike the classic tractor seeder, which covers up to 12 beds at once, this is the maximum limit for them.

By the principle of action:

- mechanical;

- pneumatic;

- vacuum.

A separate group, among others, are precision seed drills, which we will talk about in more detail later.

Tiller grain seeders

Aggregated on a cultivator for planting wheat, barley, millet, oats, rye, perennial grasses. They need a traction potential of at least 6-8 hp. Available in trailed and semi-trailed versions.

Popular modifications of grain seeders

Five-row model, aggregated with heavy tillers (weighing more than 2 centners). Moves across the field via a wheel drive. Sows an equal number of seeds per unit of time, which is achieved by rotating special cylindrical bobbins with lattice walls. Hopper capacity reaches 25 kg with seeding width up to 95 cm.

Tiller precision seed drills

Precision seeders have the most advanced design, which allows you to accurately adjust the distance between planted grains or seeds.

By the principle of action:

- mechanical. powered by a tiller wheel drive;

- pneumatic. characterized by accelerated feeding of planting material due to the built-in air

- mechanism. They differ from the first group in high cost and complexity of care;

- vacuum. their design is supplemented with hydraulic parts, compressor, pressure gauge.

2-row seeder, suitable for sowing wheat, garlic, tomatoes, etc. Versatility is achieved by changing the honeycomb drums, of which in the basic set there are 2 at once. 0.8 cm and 1 cm seeds. For work with fine-grained crops, the seeder can be equipped with drums with a smaller mesh diameter. Such a unit takes care of all the hassle from cutting furrows to compacting the soil after filling the rows. Weighs only 40 kg with a hopper capacity of 3 dm 3.

Tiller vegetable seeders

Allows to fully automate the process of sowing vegetable crops. carrots, beets, soybeans, cucumbers, tomatoes, peppers, etc. The drive mechanism is a support wheel, changing the drive sprocket of which you can change the rotational speed of the device.

Equipped with a special brush mechanism that makes seeds fall from the hopper through the hole on its back wall. It is sealed by a disc element with a series of slots of various diameters. By setting the swivel disc to the desired hole size, you can achieve a specific seeding rate.

They are found in one-, two and four-row versions with embedding of cereals to a depth of 1-10 cm. Multi-row modifications have a modular structure and are distinguished by high weight. For example, a 1-section planter weighs 7.5 kg and a 4-section seeder weighs 30 kg.

Seeders for tiller

tiller is an irreplaceable thing in the household. Thanks to auxiliary equipment, it transforms into various types of agricultural technology, minimizing the labor of farmers. Among the many adapters that must be at the farmer’s disposal, one cannot fail to mention the seeder. the main tool of labor during the sowing season. In view of the relevance of this topic, we will consider the main types of seeders for a tiller, as well as a popular DIY method.

Vacuum precision seeder SVTV-4

Designed for vegetables and some cereals. In one pass, the tiller simultaneously fills up the grains in 4 rows. With the appropriate additional equipment, the equipment turns into an 8-row seeder. In comparison with mechanical and pneumatic types, it allows you to calibrate the value between seeds to a few millimeters. At a seeding speed of 2.5 km / h, a tiller with such a seeder demonstrates high productivity. about 0.3 ha / h.

Seeder for garlic tiller

This device is an indispensable aid for vegetable growers and flower growers who grow bulbous crops. garlic, onions, daffodils, tulips, etc.

Modern garlic planters for tiller are arranged according to the principle of potato planters. There is a metal coulter for cutting furrows of the required size. Thanks to a belt or chain conveyor with special mechanisms, the garlic cloves are captured from the hopper and fed into the prepared soil. The planted row is covered with soil.

Seeders for tiller: a typology

The features of the adaptation depend on the economic needs, therefore, today 5 types can be distinguished for the introduction of seed:

- Nesting. In the process of sowing, the device places the seeds in a nesting way;

- Scattered. Seed material is evenly scattered over the entire area;

- Privates. There is a combination of row sowing and seed placement;

- Square-nested. Thanks to such tillers, sowing occurs along the previously designated rectangles;

- Precise seeding (dotted). Seed bulbs are placed at a certain distance in a wide row.

According to the designation of crops, the following types of seeders are distinguished:

- Universal. They are suitable for cereals, legumes, oilseeds and bast crops, that is, they can plant any plant with high quality;

- Special. Such devices are designed to work with certain crops. There are corn, linseed, cotton, vegetable, beet and other options;

- Combined. The devices are placed in the soil not only seeds, but also fertilizers.

New and Improved Homemade 4-Gang Seed Sower!

It is worth noting that precision planters for tillers are considered the most common and popular.

over, we are talking specifically about devices with a disc coulter, because thanks to them, the drop point of the seeds and the point for determining the seeding depth are located almost on the same mowing line.

To carry out a variety of work on personal plots, people prefer versatile options, while professional farmers use highly targeted aggregates. over, many craftsmen are trying with their own hands to create a corn seeder for a tiller (or grain) that performs a task no worse than factory models.

Seeders for tilers: types and how to do it yourself

tillers are reliable assistants in agricultural and land work, and their productivity is significantly increased thanks to specialized types of additional equipment.

Tiller planters help to plant multiple crops evenly, achieving the desired grain density.

Today, many companies offer absolutely various types of these devices for purchase, so it is important to familiarize yourself with the types and choose the most profitable option for your device. over, you should not exclude the possibility of creating a seeder with your own hands, which, oddly enough, with a competent approach, the presence of parts and drawings is an easy task.

Homemade seeder for tiller: manufacturing features

In order to obtain a truly practical device upon completion of all the necessary procedures, you must:

- Two running wheels;

- Seed box;

- Screws and nails;

- Steel sheets;

- Rubber plates;

- Sowing roller;

- Self-tapping screws, spikes, steel corners;

- Two bearings and brackets.

The process itself is simple, but requires maximum concentration, so you need to pay attention to the following features:

- A seed box can be crafted from planks (wood) (no more than 15 mm thick);

- To close them from the bottom side, you can use steel overhead bottoms (1 mm thick);

- The walls themselves are connected using self-tapping screws, iron corners and spikes;

- From the bottom of the walls of the box, thanks to nails, wooden lining is mounted (15 mm thick);

- The process of placing the seeding roller in the walls and linings is accompanied by the creation of cutouts (semicircular shape). Using screws, carefully screw the mounting brackets to the linings;

- Special rubber plates, which are placed in the inclined bottoms, facilitate the loss of seeds from the cells;

- Wheels of the created grain seeder for tiller (or corn) have hubs of 60 mm;

- Special holes are created in the hubs (the diameter is similar to the seeding roller);

- The opener can be made from a sheet of iron and then attached to the brackets;

- You can adjust the depth to which the seeds will be placed by re-securing the opener in the special holes;

- On the rear wall of the seed box, a bracket can be adapted to serve as a “connecting link” between the device and the tiller.

If a person really set himself the goal of creating an excellent “helper” with his own hands, then the described features, steps, drawings and videos posted on our website will contribute to obtaining the desired result!