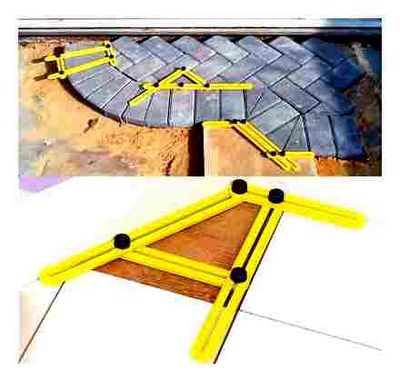

Tool to cut at an angle

Auxiliary straight line in AutoCAD

| AutoCAD drawing command | |

| Straight | |

| Definition | |

| Straight. it is an endless line in both directions. | |

| Tool | |

| Line tool. cyclical command that allows you to build auxiliary mowing lines (straight lines) starting at a common point and endless in both directions. | |

| Team | |

| Direct / Xline in AutoCAD | |

| An object | |

| Straight | |

| Line drawing commands | |

| Beam, Straight, Segment, Polylesque |

Both older and newer versions of the program use the Straight tool, which allows you to create auxiliary straight mowing lines. In older versions of the system, auxiliary mowing lines of AutoCAD were intensively used, therefore, almost every drawing began with marking the space of the Sheet (Model) of the future part, and then only outlined with segments, arcs and other objects. The drawing was being edited. In modern versions of the system, any drawing can be drawn without using auxiliary straight mowing lines in AutoCAD, because we have such powerful binding and tracking tools at our disposal.

Drawing construction straight lines by default

The Direct command is responsible for creating an auxiliary straight mowing line in AutoCAD, which can be called in the following ways:

- You can draw an AutoCAD straight line from the menu bar, item Draw. Xline string;

- You can create a straight line from the Drawing toolbar, click the AutoCAD Line button, and also on the “Home” tab of the tool ribbon in the Drawing group, select the Xline button;

- You can draw a straight line by directly typing the command name on the Xline command line.

After calling the Direct tool in AutoCAD, the command line will ask you:

You can set the reference point through which the AutoCAD auxiliary line will pass by entering coordinates in the command line or by clicking the mouse. Once you set the anchor point for the line, the system will display an auxiliary line through that point. The preliminary sketch of the straight line is attached to the cursor and rotated to follow it around the anchor point. The command line prompts you:

Now you need to indicate the direction of the auxiliary straight line in AutoCAD by specifying the second point through which it will pass. You can also set the second point of the endless mowing line arbitrarily using the mouse or by entering coordinates.

As soon as you specify the second point of a straight line in AutoCAD, the program will draw it, but it will not complete the execution of the Line command, because the command is cyclical. The previous prompt appears on the command line:

Thus, you can create many construction straight lines that intersect at one point. To complete the command, press “Enter” or interrupt the execution of the command by pressing the “Esc” key.

Box model

A simple modification of the miter box can be made industrially or at home. As a rule, such a miter box is made of plastic and has several slots, which are convenient guides for the cutting tool.

It can be used to saw slats, wooden blocks, drywall. It is possible to select an angle in the horizontal plane of 22.5, 45, 90, 135 degrees and 45 degrees in the vertical position. Although models are often sold with two positions. 45 and 90 degrees.

It is a simple and mobile model, which, however, has strictly fixed cutting angles. The quality of the cut surface also suffers, and the movements themselves must be short, which entails frequent falling out of the hacksaw from the groove.

What is it needed for?

Initially, the miter box was used as a device for cutting down the boards at an angle of 45 and 90 degrees. Modern tools allow you to cut the workpiece at different fixed angles. Swivel miter box allows adjustment of any cutting angle.

The need to cut at an angle arises with a lot of carpentry work, for example, when cutting down a door frame, because a mistake can literally cost dearly: you will have to purchase a new box. But also relatively minor work, such as the manufacture of frames, material for platbands and baseboards, does not allow distortions and inconsistencies.

A special hacksaw is required for work. It differs from the usual version by small teeth and a small set, allowing you to make a narrow, accurate cut.

The handle of such a saw is fixed at the top of the blade so that it is possible to use a hacksaw along the entire length.

Rotary mechanical miter box

When there is a need for high accuracy of cutting at any of the angles in the vertical and horizontal plane, the possibilities of the box miter become insufficient. In this case, it is advisable to purchase an adjustable mechanical miter box. a precision hand tool for high-precision sawing of wood, plastic and even metal workpieces of small and medium thickness.

The mechanical miter box consists of a metal bed, a swivel carriage and a saw precisely fixed in the guides of the swivel unit. Sawing takes place according to preset parameters. The clamping system rigidly fixes the workpiece to increase the convenience and accuracy of sawing operations. Precision miter boxes are equipped with butt or bow saws, with the ability to adjust the blade tension. Provided that high-quality saws are used, a mechanical miter box provides cutting no worse than a cross-cut saw.

Advantages: accuracy of sawing operations; long blade travel, increasing the quality and cutting speed; the ability to adjust the cutting depth and perform cuts at any angle; the ability to work with workpieces of various lengths and thicknesses; cut quality equal to that of a miter saw.

Disadvantages: By the standards of mass production, sawing operations on such a tool take a long time.

Which saws are better to use with a miter box?

In a set with a miter box, a special butt saw is usually used. Thanks to the steel backing, the saw does not bend during operation, which contributes to a more accurate and accurate cut. In this case, the butt of the saw itself acts as a limiter of the cutting depth.

You can also saw with an ordinary hacksaw, but the quality of the cut in this case will leave much to be desired. The cleanest and most accurate cuts are provided by fine-toothed blades with high TPI (teeth per inch) and minimal (or no) set-up.

Understanding Cutting Tool Geometry

Rotary type mechanical miter box

To increase the cutting accuracy, a rotary miter box is used. It is used for processing wood or plastic workpieces of medium and small thickness. In work, you can operate a hacksaw from 290-600 mm with a turn of 15-135 degrees. There are also models with the ability to rotate up to 180 degrees. Structurally, the device consists of a metal frame.

Instead of a side wall, a pivoting structure is equipped, which involves fixing the saw blade in the guides of the pivot unit. The miter box is supplemented with a butt or bow saw. The base of the miter box has a special clamp for fixing the workpiece.

Among the available models you can choose Fit Profi and Champion 180, BISON miter saw. The advantage of the design is the high precision of work, as well as a long sawing stroke, as a result of which the sawing speed increases. The cutting depth will be higher, there is a possibility of processing parts of different lengths and thicknesses.

What is the miter box for??

The miter box is a hand-held carpentry tool for accurately cutting planks and other lumber at the desired angle. When making a wooden frame, installing platbands and skirting boards, or performing any other work related to cutting boards, you will surely face the need to create a flawless corner cut. the so-called “mustache” connection. In order for the joints of the parts to fit tightly and have no gaps, the cutting angle must be as accurate as possible. Here the miter box becomes the ideal helper.

There are several design options for this device. In our article, we will dwell on the main types of miter boxes, we will tell you how to choose and use this hand tool correctly to create a flawless burr.

Making a miter box at home

If you decide to make a miter box with your own hands, then there is nothing complicated about it. At the first stage, the base material is selected. It is advisable to take a board of coniferous wood with a thickness of up to 20 mm. An oak blank is taken with a thickness of 10-15 mm. It is recommended to prepare a board for a substrate with a smooth surface and even corners.

Then it is necessary to make a box with a width of no more than 150 mm for more ergonomic work. The sidewalls are fastened to the lower plane with self-tapping screws. Edges are installed on the base.

Answering the question of how to make a high-quality miter box, you need to pay attention to the technology for making the slots. First, you should make an accurate marking with lines located parallel to each other and at an equal distance.

Use a hacksaw with a sharp blade to make the cuts. Sandpaper will help you widen the grooves.

To work with a miter box, you need to choose the right hacksaw. The canvas should be thin but strong. Fine teeth are preferred.

The Secret Formula for Making Perfect Miter Cuts When Less Than 90 Degrees

The miter box is used not only in the field of construction and repairs, but also wherever accurate and precise cutting is required. The scrap rate is reduced, and the speed of performing manipulations increases significantly.

Those people who are far from carpentry often express bewilderment at the word “miter box”, you can even hear laughter and jokes about this unusual word. However, experts easily explain the meaning of this simple word.

Technology of use

The use of a miter box greatly facilitates the work of the master. There is no need to adjust to the angle of the cut, determine it by eye or work on fixing the cutting blade. To understand how to use a miter box, you need to follow several basic steps:

Fasten the miter box with screws or a clamp on a flat surface. Make markings on the workpiece with a pencil or laser. Place the workpiece in the tray at one of the walls. The markings made should be opposite the corresponding slot with a given angle. Insert the hacksaw and cut.

In this case, you should carefully study the instructions for using the electrical device, as well as carefully use the cutting blade.

If the workpiece is asymmetrical, then its working part must exactly touch the bottom plane of the tray. When working, the force must be evenly distributed on the cutting blade. This will eliminate the breakage of soft material.

How to cut at an angle

Today it is impossible to imagine the interior of a residential building or apartment without ceiling plinths. The skirting board covers the irregularities of the suspended ceiling or wallpaper, cracks and imperfections in the walls, and gives the interior completeness. But how to make the skirting board perfectly fit in the most important place. in the corner? There are several ways.

admin, Fri Apr 2018 19:19

How to make a miter box yourself?

If desired, the miter box can be made at home. It can be crafted from wood or iron. The dimensions of the workpiece do not play a special role, but the wider it is, the more accurate your cuts will be. However, if the width is greater than the length of the hacksaw, with which you will cut the baseboards or boards, then it will be extremely inconvenient to saw, so you do not need to take a workpiece that is too wide.

First, a transverse line is marked in the center of the workpiece. Then, marks are made at a distance of 1/2 the width of the workpiece from the intersection of the straight line with the edges of the workpiece. Then these marks are connected crosswise, as shown in the figure.

Wooden miter box, fastened with self-tapping screws

Next, the process of marking the side walls of the miter box begins. Attach them to the already marked base and make marks based on the base markings. Then draw straight lines from these marks across the entire wall.

The scheme of making a wooden miter box

After that, the process of mounting the miter box begins. The walls must be attached to the base with self-tapping screws if the fixture is made of wood or chipboard or corners with bolts if it is made of steel. Only after installation in the miter box are sawed slots for the saw.

After making the slots, the miter box is ready. If you have a large amount of work or want to repair regularly (on a professional basis), this simple device can speed up the process of cutting skirting boards by 5-10 times.

If the angle is not right

Unfortunately, in some cases, the angle between the walls in the room is not straight, but sharp, or, conversely, obtuse. This is due to structural defects that have arisen through the fault of non-professional builders, the architect’s idea or the result of soil subsidence some time after the construction of the building. This is especially common in village houses and summer cottages.

House plan with sharp and outer corners

No miter box or a drawing replacing it will help in this case, and you will have to do the markup in place.

- Attach the workpiece to one of the walls so that it rests against the other wall with its end.

- Run the line on the ceiling along the workpiece.

- Perform the same operation against another wall.

- At the intersection of the two lines, put a mark on the workpiece itself.

- Draw the line from the mark to the corner of the workpiece and cut along it.

- Do the same with the workpiece, which you will attach to another wall.

- Glue both blanks; they will come together tightly.

Method of joining platbands without trimming

Platbands today are often not cut at an angle in order to then join together, but make a joint at right angles. This method of joining platbands does not require any special trimming, which is very convenient. In addition, this method looks more modern and attractive.

Angle trimming with a miter box

If, nevertheless, it is necessary to cut this or that part at an angle, then you should stock up on a miter box. the simplest device that looks like a small box. The miter box has slots that are designed for a saw or a long sharp knife. Of course, these slots are made to form an even and precise 45 degree angle.

However, a miter box can have many slots at once, at different angles. This is convenient, because with one tool, you can cut any part at different angles.

There are adjustable miter boxes on sale. The slots in such a miter box can be adjusted, which allows the master to set exactly the angle that is required at the moment. In particular, it is quite easy to transfer the slots of such a miter box to a position of 45 degrees.

Now the workpiece can be cut easily. A baguette, platband or plinth is placed in the miter box, after which a saw is inserted into the slots and the excess is simply cut off. The angle ends up being perfect, exactly 45 degrees.

What if there is no miter box? Very simple. You need to make a template according to which it will not be difficult to transfer the necessary markup to the blanks. As a template, you can choose thick cardboard or something else that will be appropriate in this case.

How to cut a skirting board without a miter box?

The easiest way is to draw the future cut line on paper (cardboard, wallpaper), and then, attaching the baseboard blank to it, cut.

To do this, you must first attach the skirting board blank to the paper and draw two parallel mowing lines that will mark the sides of the skirting board. Then, using a protractor, you will have to measure 45 degrees and draw the line of the future cut. Then the drawing is used in the same way as the miter box: a blank is placed on it and the excess is sawn off along the mowing line.

How to cut the corners of a skirting board without a miter box

The disadvantage of this method is that the saw will have to be held on weight, focusing on the drawing, and not inserted into a prepared slot.

Trimming parts at an angle using a protractor

You can trim the part at an angle using a protractor. This is a measuring tool that is easy to use, and which is designed specifically to measure angles or make the necessary markings on certain parts. The protractor is applied to the part, the angle is marked and the markings are made with a pencil. Using this marking, it will not be difficult to cut the workpiece at the desired angle.

Circular Saw

Plywood sheets can be cut into various shapes using a circular or circular saw, but the main purpose of these tools is to create rectangular cuts. It is very difficult to get a neat cut when cutting material because the rotational speed of the discs is very high. In this regard, preference should be given to those cutting wheels that have small teeth and are used for working with wood. When processing plywood, it is good to use cut-off wheels designed for sawing chipboard.

Tip: when cutting the plywood sheet, make sure that the pressure on the sheet is low and the rotation speed of the disc is low.

When making furniture or repairing it, you often have to choose how to cut laminated plywood. To get a clean cut, it is necessary to select discs or blades with frequent and fine teeth. The angle of their sharpening, as well as the shape, is of great importance. It is advisable to select discs with a positive sharpening angle and a different shape of the teeth (there is an alternation of trapezoidal and straight teeth). If the disc has negative sharpening angles, then it is necessary to reduce the speed, otherwise the wood will burn.

Important: the larger the disc diameter, the wider the cut will be and, accordingly, the number of chips will increase. It is completely impossible to avoid the formation of chips, but it is really possible to reduce their number and size to such an extent that subsequent processing could completely eliminate all roughness.

A relationship has been established between the size of the chip and the saw teeth: small ones leave less damage than large ones. The set of teeth has an impact on the cleanliness of the cut plywood. Best results are obtained with minimal wiring. You can check this parameter using a regular ruler. Sawing a thick sheet with a disc with a minimum set of teeth should not be, since increased friction will cause it to burn and pinch the disc.

Zero clearance

The principle of this technique is to keep the distance between the blade sole and the pressure plate as low as possible. This avoids breaking off the top layer of the plywood. This effect can be achieved by attaching a cover plate to the tool sole. The trim has a slot to retain the ability to cut along the intended mowing line. Thanks to this, the teeth are guaranteed to cut small chips and do not break out the material.

It is important to exclude mechanical damage to the sheet surface by the overlay. The pad should be changed every 5 meters of cut. The use of pads made of more durable materials (metal, plastic or fiberglass) eliminates the need to frequently change pads, the surface of which must be pre-polished.

How to get the perfect cut

In order to get a perfect cut from the front side, you can use both a hand saw and use a power tool. There are several techniques to help you achieve a high-quality cut on plywood. Here is some of them.

Adhesive tapes

To protect the back side of the plywood, tape is glued along the mowing line of the cut. This method helps to prevent large pieces from breaking off, which is especially effective if the decision is made to use a hand or electric jigsaw. However, not all adhesive tape is suitable for this purpose. For example, masking tape in this case will be completely useless due to the small margin of safety.

After the saw blade or electric jigsaw has stopped working, remove the tool after unplugging it from the mains. Then proceed to peel off the tape. At the same time, great care should be taken not to cause the small fragments of the laminated surface to come off with sudden movements, which inevitably form during cutting. Therefore, it is necessary to abandon the use of materials with a strong adhesive base. When choosing such a tape, one should take into account its adhesive ability and ease of cleaning from a rough surface.

Electric jigsaw cutting

To obtain an even cut, the sequence of actions should be as follows:

- Securely fix the material.

- If possible, cut perpendicular to the grain of the wood, otherwise it will be very difficult to get an even edge.

- In no case should you put pressure on the tool, the cutting speed will not increase from this, but the tool is guaranteed to break.

- The surface of the teeth should be lubricated with oil to facilitate work (when working with heavy wood).

- It is undesirable to use the tool for a long time due to its heating and engine damage.

- After use, you need to clean the jigsaw and lubricate it.

Hand saw

When cutting plywood with a hand saw, physical effort has to be made due to the high density of the material. This tool is used when it is necessary to cut a sheet of plywood into equal pieces.

A manual jigsaw is considered the best tool and allows you to decide in advance how to cut plywood without chips, saving yourself the need to purchase electrical tools. With its help, you can make a small number of elements of complex shapes. Having certain skills in working with a jigsaw, you can make a neat cut, however, due to high labor costs and low productivity, this method cannot be called optimal.

If you don’t have power tools or a simple jigsaw at hand, then you should resort to using a simple hand saw. To cut the sheet conveniently and avoid chipping, the tool blade must have a large number of small and well-sharpened teeth. The angle of inclination of the saw to the plywood sheet must be sharp. It is recommended to avoid jerking and make steady movements with strong pressure.

Tip: The cut of a conventional saw is rough, therefore it is recommended to process the end parts with emery after the end of sawing.

Sawing with a circular saw

To effectively cut a sheet with a circular saw, you should adhere to the following rules:

- Place the plywood sheet on a stable support and make the first notch closer to the middle of the sheet.

- Adjust the cut in depth. To do this, lower the disc and start cutting, while the immersion depth of the disc should be 0.5 cm greater than the thickness of the blade.

- Position yourself to the side of the line of action of the saw to avoid injury due to the high probability of kickback.

- Prepare the saw for making the required cut. To do this, attach the saw shoe (part of it in front) to the blade and install the blade on the cutting line, having first bend the cover.

- Make sure there is no interference at the bottom of the sheet.

- Switch on the saw and slowly immerse the blade in the material. Hold the saw firmly to prevent kickback. After plunging into the slot of the disc and installing its shoe on the surface of the sheet, return the protective casing back.

- Guide the tool along the mowing line to the end of the blade.

- Turn off the saw and only after it has come to a complete stop, remove it from the slot.