Changing lawn mower spindle. 13 THINGS YOU SHOULD NEVER DO TO YOUR MOWER

How to Know if Mower Spindle is Bad- 4 Signs

A lawn mower is made of many parts, including a spindle. These components must be in good order for the mower to function effectively. However, most parts keep improving with technology, but others never change, such as the spindle.

If the spindle is bad, your lawn mower will not function. That’s because the spindle holds the blades. These blades are designed to give you an even cut for your yard to look spectacular. Therefore, you should know how to spot the difference and tell where things went bad after the spindle goes out.

It is easy to tell whether the mower speed is bad. You start to experience vibration, squealing and uneven cuts. The moment you experience such signs, you must check whether the spindle is bad and requires changing.

- How to Know if Mower Spindle is Bad

- Signs of a Bad Mower Spindle

- 1. Uneven Cuts

- 2. Squealing Noise

- 3. Vibration and Buzzing Noises

- 4. Bent or Broken Parts

- Replacing a Mower Spindle

- 1. Park the Mower

- 2. Prepare the Mower

- 3. Remove the Blade Spindle

- 4. Replace Bearings

- 5. Change the Spindle

- FAQ: How to Know If Mower Spindle Is Bad

- What will a mower spindle do?

- How do I know a bad mower spindle?

- How often should I grease my lawn mower spindles?

- Author

How to Know if Mower Spindle is Bad

If you are familiar with the mechanical parts of a lawn mower, then you know what a spindle is. Again, you may also be aware of what will happen after it goes bad. The part is essential and responsible for spinning blades.

When taking maintenance practices, this is one of the parts to include in the list. It requires frequent checking and greasing.

The mower will have the same number of spindles depending on the number of blades. And therefore, with a problem with the spindle, the mower blades malfunction.

If you’re looking for ways to know whether a mower spindle is bad, read on:

Signs of a Bad Mower Spindle

Most mechanical parts give you a warning sign before breaking entirely. When you see part of these signs in your lawn mower, you need to change your spindle and prevent further damage immediately.

A bad mower spindle may cause many damages to the blades, deck, and even the lawn. Consider these signs to determine a bad spindle:

Uneven Cuts

The moment you find the lawn mower cutting unevenly, it could be a problem with the spindle. This is one of the problems easy to notice. After the spindle in the mower goes off the axis, it makes one blade not move evenly with the others. That damages the lawn with uneven cuts.

Remember that it will take months to repair those damages, particularly when the blade cuts the ground. The grass will either be killed or burned after its uprooted.

Squealing Noise

Those spindles attached to the riding mower will be larger than those on other mowers. Some mowers have two or more spindles, which in return experience squealing noise with a bad spindle.

In addition, there will be wear and tear on mowers bearings, or even broken spindle, thus, needing replacement.

Vibration and Buzzing Noises

The other way of determining a bad mower spindle is experiencing vibrations and buzzing sounds. These sounds are only expected with a bad spindle. Buzzing noises will happen before vibrations.

When you experience vibrations, they occur because of the deck; and it will shake the entire lawn mower with such force.

If you are troubleshooting the problem, start by changing the frozen wheel first. After realizing that buzzing or vibration continues, change the mower spindle.

Bent or Broken Parts

Sometimes, a bad spindle will be visible after the spindle is bent or broken. After reaching the depth, the mower blade will hit other blades or stop. If the blade hits the deck, it may cut through it after hitting it many times.

You can hear loud cracking noises that are impossible not to hear. After seeing uneven grass and some parts falling, that means the spindle is bad.

Replacing a Mower Spindle

Now that you have checked the signs of a bad mower, you have decided to replace the spindle. Before that, there are tools you need for a DIY project. they include:

- Safety glasses

- Jack stand or concrete blocks

- Hydraulic jack

- Deep socket wrench set

- Screwdriver

- Work gloves

- New spindle

If you want to replace the spindle, here are the steps to follow:

Park the Mower

Search for a flat ground place to park the lawn mower. It should be dry to allow you to work underneath the deck.

Prepare the Mower

Prepare the mower by allowing it to cool down after operation. Engage the parking brake and remove the key from the ignition. Underneath the tires, place blocks to prevent it from rolling back.

Remove the spark plug and drop the deck. With working gloves on, jack up the power.

Remove the Blade Spindle

Start by removing the blade and then the spindle. The blade always comes first for you to access the spindle. Take precautions with the spindle not to fall on you. Remember to put your safety glasses on because there will be falling debris.

Replace Bearings

If you find the spindle in good condition, the bearings may have a problem. Replace them, but that’s not always the situation.

Change the Spindle

Once you have removed the worn-out spindle, put the new spindle back to the shaft. Push it up until it reaches the base of the deck.

Once done, put everything back to normal. You have now changed the simple, and the lawn mower is ready to test.

FAQ: How to Know If Mower Spindle Is Bad

What will a mower spindle do?

With a riding lawn mower, the spindle is used to hold the mower blades. The blades are attached to the spindle and rotate while the machine is operating.

Each riding mower will have one or more spindles – depending on the size of the mower and manufacturer.

How do I know a bad mower spindle?

A mower will make buzzing noises when it has a bad spindle. That may not be the only way to know a bad mower spindle. Other methods include uneven grass and vibrations.

How often should I grease my lawn mower spindles?

Generally, the caster wheels and spindles are mostly greased. You have to grease once a month not to damage the moving interior parts.

If the mower is for commercial use, grease it every day, but depending on usage.

If you are looking at how to know if mower spindle is bad, we have shared it all.

Check through the article to know how you can identify a bad spindle.

However, the common ways include squealing, uneven cuts, and vibration.

Author

Hi, I’m Ricky. I’ve been involved in lawn care and landscaping from when I was 15. To be honest, I didn’t like the idea of pushing mowers, collecting grass clippings, and maintaining flowerbeds at the time. But having seem the passion my parents had for gardening and outdoors and the effort they put in maintaining the health and beauty of our landscape, I couldn’t help but not only admire their hard work but also I became a part of it. As someone who loves to spend time with nature’s best, I find myself learning a lot more about gardening and outdoors on a daily basis. Not to mention I love to share the knowledge I’ve gathered over the years with my readers at We Mow Dallas. To be clear, I don’t have a Master’s degree in gardening or anything like that. Everything I’ve learned about gardening, landscaping, and lawn care spring from passion and engagement with my parents. And with a ton of free information out there, plus the ability to run tests and determine what works best for lawn care and landscaping, every day is an opportunity to learn and implement something new. My goal with We Mow Dallas is to teach you exactly how to maintain your lawn and landscape. And since I walk the talk in reality, you shouldn’t hesitate to join me in this wonderful world of landscaping and lawn care. View all posts

THINGS YOU SHOULD NEVER DO TO YOUR MOWER

Lawnmowers are one of the most essential tools in a homeowner’s arsenal. They keep our lawns tidy and help us manage outdoor spaces, but like all tools, they must be used appropriately to work effectively and last long! We want your property (whether new or old) to look its best at all times. Sometimes we can make mistakes when taking care of this task which could lead down dark paths. namely, doing 13 things listed below.

DON’T LET YOUR ENGINE GET LOW ON OIL.

You can always appreciate the importance of checking your lawn mower’s oil before every use. It might be one small thing that saves you from having a massive problem with overheating and smoking. Still, it will also reduce wear on equipment used in this process, like engines or cutting blades- meaning they’ll last longer

DON’T LET YOUR RADIATOR COOLANT GET LOW

That’s right, people. Your new lawnmower is ready for action and will easily cut the grass if you remember one thing: check your coolant level! If it’s low or depleted, this can lead to overheating, leading me into disastrous territory where things start acting weird.

After running all summer continuously, ensure an annual review is done on time. Checking the coolant level before each use will help prevent emergencies from happening too soon! So any disasters that don’t occur until past their due date have saved many lives.

DON’T SUFFOCATE YOUR ENGINE

Your mower engine needs air circulation to prevent overheating. The fins on it are designed for this purpose, yet when you clean them, they can become clogged with dirt. This clogging leads directly toward an overworked motor which is dangerous for yourself and those around you! It could cause fires.

If there’s too much gas inside the lines. So ensure everything stays clear by washing these necessary cooling devices every once in a while. Or risk having a burning sensation whenever we use our lawnmowers.

DON’T HIT TREE STUMPS WHILE YOU CUT THE GRASS.

When it comes to lawn care, efficiency is vital. No one wants to spend an entire Saturday afternoon pushing a mower when they could be doing something else. That’s why many people invest in riding lawnmowers. They may cost more upfront, but the time and energy they save are well worth the investment. However, even the best mowers can run into problems if they need to be used properly.

For example, if you hit a tree stump with your zero-turn mower, you risk bent blades or damaged spindles. And if your riding lawn mower hits something significant, it could be damaged beyond repair. So if you see any signs that your mower has been running into something, it’s best to call a professional. Otherwise, you could spend more money on repairs and lose productivity in the long run.

DON’T TRY TO USE YOUR MOWER TO QUICKLY RE-SPOOL ROPE OR BARBED WIRE.

While your mower will get the job done a lot faster than you could, this is not a very cost-effective method. You will probably end up needing a major repair. Here are some signs of a lousy mower spindle.

- Uneven grass height after cutting your lawn

- Squealing noises while using your mower

- Louder than normal buzzing sounds and random vibrations

- Broken or bent mower parts

- The spindle fails to immediately heat up after starting up your mower

How To Tell If A Mower Deck Spindle Is Bad (4 Telltale Signs)

Mowing your lawn and it does’t seem to be working effectively? There are four telltale signs that your mower deck spindle is bad. Whether it be vibration or squealing sounds, let’s take a look at the key signs that your spindle is bad.

There are different components to a lawnmower that make up its ever-changing technology. Some parts, however, remain the same and have never changed. One of those parts is the spindle which a significant part that turns the blades.

The blades on the deck are designed to give an even cut to make the yard look spectacular. If a spindle is going out, you will be able to spot the difference and even tell where it went bad. There are different ways to know if the spindle is going out.

You can tell if a mower deck spindle is bad by noticing uneven cuts, squealing, and vibration. Having bent or broken parts is another way to know if the spindle is going out. As soon as you notice these signs, it is critical to discontinue use and change the spindle immediately.

What Is a Lawn Mower Deck Spindle?

Mechanics and those familiar with the parts of a mower know what a spindle is. They also know what happens when it goes bad. It is the part responsible for spinning the blades while the PTO clutch is running.

It is a part that needs to be on the maintenance list when it comes to greasing and checking. To best describe, the spindle is a part that is an axis that motions the spinning of the blade shaft. It is located on the mower’s deck and connected to each of the blades.

Mowers have one to three spindles, depending on how many blades the mower has. It connects directly to the pulleys and spins with the force of the belts turning the pulleys. If there is a problem with the spindle, then the blades will malfunction.

The Four Signs the Spindles are Malfunctioning

Most mechanical parts will give off warning signs before they break entirely. If any of these signs are present, it is critical to change the spindles immediately to prevent further damage. Damages may occur to the deck, blades, or the lawn.

The Lawn Will Have Uneven Cuts

The first and most noticeable problem when the spindles go out is the yard is cut uneven. If the spindle goes of the axis, the blade will not move even with the others. When this happens, the lawn can become damaged and uneven.

It can take months before the damage is repaired, especially if the blade cuts into the ground. The grass can get burned or killed by being uprooted during the cut. The common causes are the bearings loosened or the spindle shifted.

There Will Be a Squealing Noise

The spindles on riding mowers are larger than other mowers. Mowers with two or more blades may experience the squealing when the spindles are fixing to give. The common cause is wear and tear on the bearings, or the spindle is broken and needs to be replaced.

If There is Vibration and Buzzing Noises

Buzzing noises are expected when the spindle is going bad. This happens right before the vibration occurs. When the vibration happens, it is usually the deck, but it is with such force, the entire mower will shake.

The common issues are the same as the squealing noises. In troubleshooting, try to change a frozen wheel first. If the vibration or buzzing sound is ongoing, continue to change the spindle.

Broken or Bent Parts Can Mean the Spindle is Worn

It can sometimes become visible when the spindle is broken or bent. When it reaches this depth, the blade may stop or hit the other blades. It can even hit the deck and cut through it if it is hit enough times.

There will be loud cracking noises that are impossible not to notice. When the grass is cut uneven, and the other parts begin to fail, it is time to replace the spindle.

Lawn Mower Parts

Search and shop all the parts you need for your riding lawn equipment and Gator UTV including lawn mower blades, filters, belts, spark plugs, oil, and home maintenance kits.

Find Parts

Search part numbers and John Deere parts diagrams to identify exactly what you need to keep your equipment running smoothly.

Quick Reference Guides

As a John Deere owner, when it’s time to maintain, service or repair your equipment we have easy-to-use information sheets that keep your John Deere equipment running well.

Home Maintenance Kits

Feel confident in tuning up your lawn mower or garden equipment this season with our Home Maintenance Kits. Easily find the right product so you can DIY and save!

Looking for your Serial Number?

Finding your lawn mower’s model number and serial number is as easy as locating the identification tag on your machine. As seen in the example, the model number will be displayed below the MODEL heading (Example: Z235), and the serial number will be underlined on the top-right corner of the tag (Example: 130002).

If you’re looking for the engine number, that can be found directly on the engine itself.

Home and Garden, eat your heart out.

Get the latest on how to care for and enjoy your yard and garden. The articles and videos are informative and the ideas are amazing.

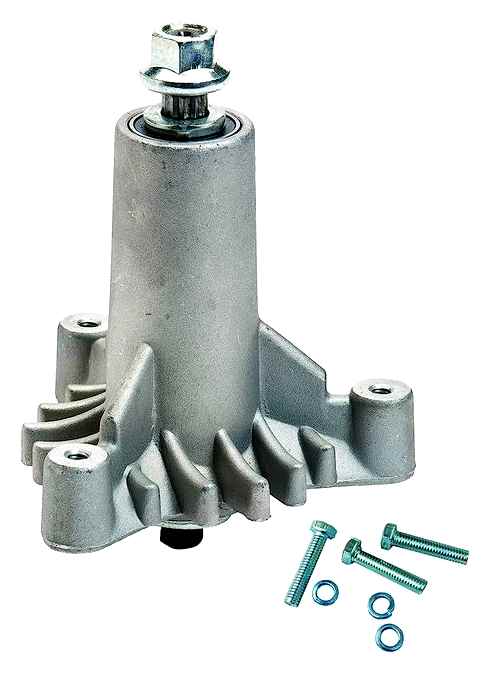

Craftsman Riding Lawn Mower Spindle Assembly #532192870

MowerPlus Mobile App

MowerPlus is the app you need to keep your John Deere riding lawn mower running well and your lawn looking great this season. The app tracks and records yard tasks and serves as a one-stop shop for seasonal care tips and maintenance activities. Know your mower and know how you mow with John Deere’s MowerPlus app.

The Right Part. The Right Price.

At John Deere, you get the value of choice for your maintenance and replacement parts for all makes and ages of machines – at any budget.

Genuine Parts

Genuine John Deere Belts Blades are your best choice for your newer machines.

Alternative Parts

Alternative Parts are an economical solution for your John Deere equipment.

The John Deere Easy Change™ 30-Second Oil Change System

Never drain engine oil again.

We’ve changed the oil change. Revolutionized it really. See how fast and easy changing your oil can now be on 100 Series Riding Lawn Tractors with the John Deere Easy Change™ 30-Second Oil Change System. Only from John Deere. Included on the E120, E130, E150, E160, E170, and E180 models.

Step One. Take it off.

Lift the hood. Make sure the engine is cool, then, twist to remove. It’s that simple.

Step Two. Twist and lock.

Grab the new Easy Change™ Canister, twist and lock into place. Make sure the arrow on your Filter System aligns with the arrow on your engine.

Step three. Done.

Close the hood and mow. John Deere recommends the Easy Change™ 30-second Oil Change System every 50 hours or at the end of your mowing season. Don’t drain engine oil ever again.

Draining engine oil is so 2017.

The engine modifications and new technologies are in. The re-envisioned oil filter with a media designed to resist breaking down in oil over time is here. The thousands of hours of testing are done. The end result is an all-in-one, oil and oil filter system like no other. The first of its kind. And thanks to the new John Deere Easy Change™ 30-Second Oil Change System (“System”), you’ll never have to drain the oil from 100 Series Riding Lawn Tractors again.

Guide to Lawn Mower Spindles

Here’s why: The new System captures contaminants and recharges your engine with nearly a quart (0.8qt) (0.76 l) of new oil. In fact, this System increases the amount of oil in the engine by nearly 40%. 2 Your engine likes that.

What do you mean, I will never have to drain oil from my engine again? How is that possible? The answer is simple. We have developed a better filtration system and filter design for our 100 Series Riding Lawn Tractors 1. This fully synthetic filter media has greater surface area which increases its capacity to hold harmful contaminants. What’s more, the filter media is designed to resist breaking down in oil over time. Which means you’ll get a cooler running engine. And a cooler running engine and better filtering helps increase engine oil life. John Deere’s recommended oil service for 100 Series Riding Lawn Tractors 1. is to change the System every 50 hours or once a season, whichever comes first. Remember, the System replaces a portion of your engine oil. And that’s plenty.

The System uses John Deere Turf-Gard™ Oil. Using John Deere Turf-Gard™ Oil ensures you are using the exact oil specified by John Deere engineers.

Testing. Testing. Testing. Thanks to thousands of hours of rigorous and extensive testing, you can feel confident your engine will run for years to come.

1 The John Deere Easy Change™ 30-Second Oil Change System is available on E120, E130, E150, E160, E170 and E180 Lawn Tractors today.

2 Compared to similar V-Twin engine models that do not have the John Deere Easy Change™ 30-Second Oil Change System. That includes equivalent Deere 2017 models and 2018 models without the System.

Frequently Asked Questions:

What is new with John Deere Riding Lawn Equipment?

We are excited about the exclusive John Deere Easy Change™ 30 second oil change system. Exclusive to John Deere and only available on certain models of the new 100 Series Lawn Tractors. These tractors are designed for ease of use for both operation and maintenance. The John Deere Easy Change™ System (“Easy Change”) allows the user to easily complete the recommended engine oil and filter maintenance in 30 seconds.

What is this new oil change system?

We changed the oil change. The all-in-one oil and oil filter system gives the owner the ability to change a portion of the oil and the filter in less than 30 seconds.

What happens to the rest of the oil in the engine when the Easy Change system is replaced?

The Easy Change system replaces.8 quart of oil. The remaining oil in the engine is refreshed by the charge of new oil included in the replacement Easy Change system. Combined with 40% more engine oil capacity, improved filtration and cooler running temperatures which help extend oil life, it is no longer necessary to remove and dispose of all the oil in your engine during service.

What makes the Easy Change system unique from other filters?

It is not just a filter. It is a newly developed technology system that allows a new “filter” to come already charged with oil and allows you to remove an existing filter and the contaminants inside without tools and without making a mess. Beyond the filter, technology within the canister and on your engine makes this possible.

Models with the Easy Change oil system use a fully synthetic filter that has more capacity to trap and hold contaminants. The larger surface area of the Easy Change canister acts like a radiator helping the oil to stay cool.

Does the Easy Change system somehow decrease the life of the engine?

The John Deere 100 Series lawn tractor models, with and without Easy Change, are specified for the same lifetime and are rigorously tested to the same standards to ensure the life of the tractor meets expectations.

Can I add the Easy change system to an existing tractor?

Because this system also requires unique features within the engine, the Easy Change system cannot be added to an engine that was not equipped with it at the factory.

Can I change all the oil if I choose to?

You could if you wanted to. There is an oil drain plug. It is not required for maintenance.

How often do I need to change the Easy Change canister?

Every 50 hours or once a year. The 100 Series Lawn Tractors with and without the Easy Change system have the same maintenance schedule.

What type of oil is recommended?

We recommend only John Deere Turf-Gard™ 10W30 Oil. The Easy Change canister comes pre-filled with John Deere Turf-Gard™ 10W30 oil.

How do I recycle the old oil?

Many local government recycling programs, authorized retailers, auto repair stations, and auto parts stores will puncture and recycle used oil filters and oil.

Do I ever need to add oil?

Yes. Consistent with our service recommendations for this product, you should check oil level daily and add oil if required.

Riding Mower Spindle Mount Deck Repair and Reinforcement

Spindle reinforcement rings are circular brackets cut from plate steel that provide additional mounting strength to your riding lawn mower deck. They strengthen the mounting location where the spindles for the blades are bolted on. If you hit a larger rock, uneven ground surface, or another object with a blade like I did, it can significantly damage the mounting holes. In my case, it ripped the bolt through making it impossible to re-attach the spindle.

If your deck has damage to the mounting holes for the spindles, these rings can save you from replacing your deck.

I had to learn the hard way on this one. The weakest point on my Troy-Bilt Zero Turn lawn mower definitely seems to be the deck. Quick advice, do your due diligence and research as much as you can before making purchases, including riding lawn mowers. This one certainly gave me some buyer’s remorse and a bunch of repair headaches.

First Deck Damage

The first time I had a spindle rip through the mounting holes I wasn’t sure what I was going to do. I talked to a friend of mine who suggested we reinforce the metal. He happens to have a plasma cutter and had some plate steel laying around. It also worked out for me that he keeps a lot of scrap metal around which frequently comes in handy. With his help, we made a cardboard template by tracing out the shape. From their, we traced out a ring onto the plate steel from our template. The next step was to cut it out using the plasma cutter, then weld it into place.

Second Spindle Damage

This one was a chain reaction of events. It started when I mowed over a rock that is mostly in the ground, only sticking out what would seem an inch above the ground. I’ve gone over this rock before without any problems. However, one of the first mowing days of the season when the grass was still fairly tall, I apparently hit it wrong. This forced the spindle to pull threw metal mounting whole of the mowing deck. Perhaps the ground around the rock sank down a bit or had a bit of erosion over the winter.

I assumed I would be calling up my friend again to ask him to help me build another plate ring, but then I found a pre-cut solution…

Ready-Made Spindle Mount Reinforcement Brackets

While looking for a replacement spindle, I found these reinforcement steel plate rings on Amazon that fit my particular mower, this was a 3-pack. You can find reinforcement brackets for other makes and models as well. Just search for your particular make and model on Amazon for “Spindle Reinforcement Ring”. After coming across these, I went ahead and ordered 2 more brackets. I figured it was only a matter of time before I would have damage to the third one. This seemed like a good time for some preventative measures for the third spindle mount.

The Damage

Two bolts pulled through the mower deck sheet metal (left and right). Notice the cast metal broke off in the upper mount area of the spindle as well. If you’ve had a similar experience where your deck is damaged, you may find you need to hammer some of the sheet metal back down flat again. Or, you may have to even cut or grind some of it away for a reinforcement ring to fit flush.

You can simply have the spindle bolts hold these on, or, like I did, weld them into place. It’s completely optional. Just be careful if welding you don’t burn through what is likely fairly thin metal on the deck. Build up your weld on the spindle reinforcement ring first.

Particularly decks with fairly thin metal. The thicker plate steel makes it nearly impossible for a bolt to rip through the mounting hole like it did on the sheet metal deck.

Hopefully this article helps some of you out there from having to consider buying a new deck for your mower because of spindle damage. Feel free to leave any questions in the Комментарии и мнения владельцев section below.

Leave a Comment Cancel Reply

You must be logged in to post a comment.