Cutting monolithic polycarbonate at home

How to cut monolithic polycarbonate

Did you like this material. tell your friends:

Monolithic polycarbonate is a polymeric sheet material that due to its unique qualities. impact resistance, transparency, flexibility and ease of installation is becoming very popular and surpasses in many ways glass and other polymers. The material is easy to work with, but for a proper and quick assembly it is necessary to know the basic rules of its cutting and the right tools for the job.

The main methods of cutting a polycarbonate sheet

Recent trends suggest that more and more people began to carry out the work once left to the experts themselves. This is especially true for those citizens who live in private homes, and even for gardeners who devote themselves to seasonal work. In early spring, more and more people go out of town for a weekend to tidy up properties left unattended for the winter. Work begins, as it is known to all, not with the house, and with the garden plot, for which the whole point of this sortie. Here are arranged new seedbeds, feeding plants, shrubs and trees. over, built a summer shower, greenhouses and hothouses.

In order to build greenhouses, hotbeds, seedbeds, etc., Use monolithic polycarbonate. Polycarbonate is the toughest of all transparent materials available on the building trade.

And the most popular material that is used in this kind of construction work, now is the polycarbonate monolithic, cutting to size which has its own characteristics. They are due to the special structure of cast panels. Cutting of cellular and cast polycarbonate is not different.

Preparation and marking of sheets

Before you start cutting polycarbonate in the greenhouse or any other building, you must first perform preparatory work and make the appropriate markings on the material.

The first thing you need to do is to completely clean the place where you plan to cut the polymer material. All debris and unnecessary items must be removed. It is necessary not because of considerations of cleanliness, but so that during the work nothing distracted from the process. Once the surface is prepared, it is necessary to put a sheet of plywood or fiberboard board on it. only after that is the place for cutting as flat as possible.

Cutting Square holes in perspex and polycarbonate

On the workplace should put a sheet of polycarbonate. In the case that the material has a laminated surface, mirror or a special coating, this side should look up. As long as the material is not cut, the protective film should remain in place.

Preliminary marking should initially be applied to a blank sheet of paper as a scheme to scale. After that, you will need to transfer all markings from the paper sheet to the polycarbonate. For measurements at home is best to use a tape measure or a metal ruler. To apply the markings use a black marker. If you plan to work with large-sized polycarbonate, many experts recommend putting a board with a width of 10 cm on the polymer material and move only on it. This approach will prevent damage to the polycarbonate.

In the place where you plan to cut the sheet, you need to put on the right and left sides of the mowing line of the cut wooden planks about 4 cm high and 10 cm wide. The ends of the boards at the same time be sure to look out on both sides of the polymer material.

The movement should be carried out on the board in the same way as at the time of drawing the appropriate markings. Only in this way you can not damage the material, carrying out all the work at home.

Is it possible to cut polycarbonate

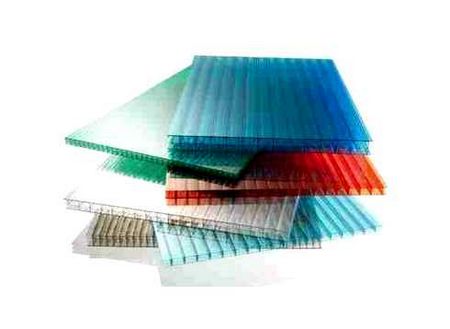

Undoubtedly, cutting polycarbonate at home is possible, but it is important to understand that depending on the selected material, the specifics of the work may differ slightly. On sale you can find a monolithic or cellular polycarbonate. The peculiarity lies in the presence of special partitions of the honeycomb material. Before you start the work, you should first study all the nuances.

Cutting polycarbonate at home

Recently, in many construction operations polycarbonate has replaced a heavy, fragile and relatively expensive silicate glass. This practical and affordable material is used for decorative glazing, the construction of elements of urban infrastructure, the construction of greenhouses and hothouses, the construction of the roof of pergolas, sheds or terraces. The durability and reliability of the structure from it depend on compliance with the technology of processing and correct installation. A frequent reason for the rejection of the material during the work is improper cutting of the sheets, so inexperienced masters part of the question of how and what to cut polycarbonate, so as not to damage the panel. In this article, we will tell you what tools can be used for processing, and how to use them correctly.

angle grinder

The most effective tool with which to cut a sheet of polycarbonate plastic is the usual angle grinder. Since this material, especially honeycomb, easy enough to handle, even the cheapest Chinese models can handle the cutting. Experienced craftsmen note that it is better to perform straight cuts of great length with an angle grinder. Cutting polycarbonate with this tool along the curve is possible, but it requires a lot of experience. To avoid spoiling the material when cutting, you must observe the following rules:

- To cut sheets of this material use an angle grinder with a cutting wheel for metal with sharp, frequent teeth.

- When cutting sheets of polycarbonate plastic, it is better to use an angle grinder at low speed to get an even cut, and the edges of the material without burrs.

- If you need to cut cellular polycarbonate, the cutting wheel of the angle grinder can be placed strictly between the ribs.

Note! Angle grinder refers to high-speed tools, to work with it without experience is difficult enough. To properly perform the cut and not to damage the material, you can practice on the rest of the polycarbonate.

Electric jigsaw

Another tool that can be used to cut polycarbonate is a household electric jigsaw. It is considered a universal tool for sawing materials of different density and thickness. The jigsaw blade is fixed only on one side, so it can be used to cut holes and curved cuts in polycarbonate. To use this tool, it is necessary to observe a few rules:

- To process sheets of polycarbonate plastic use a jigsaw, the cutting blades of which have fine teeth.

- To ensure that the edges of the polycarbonate after sawing was flat, it is necessary to use a new, sharp cutting blade.

- To obtain a smooth, neat cut, you can use a metal cutting blade, which does not tear the polycarbonate, but cuts.

- When processing monolithic plastic of great thickness with an electric jigsaw, a large amount of chips is formed, which must be promptly removed, so that they do not interfere with sawing.

Important! Professional craftsmen use the jigsaw to make only curved, curved cuts, as it takes much longer to saw in a straight line than with an angle grinder.

Stationery knife

At home, polycarbonate can be cut with a regular office knife. Cellular plastic with a cellular structure is processed with this tool more often. Monolithic polycarbonate can not be cut with a knife, as it is too hard. To make the cut turned out even, it is better to adhere to the following technology:

- To cut a sheet of polycarbonate plastic, you will need a high-quality, sharp office knife.

- Polycarbonate with a clerical cut in two steps: first, a small incision is made so that the tool does not slip, and then gently finish cutting the material.

- Chancery knife used to cut polycarbonate honeycomb thickness not more than 4-6 mm.

Note that with a box cutter perform a shallow trimming and fitting of sheets of plastic, as to make them cuts of great lengths for a long time and uncomfortable. An ordinary office knife can quickly become blunt or break when doing this.

Cutting technology

When cutting panels of polycarbonate plastic, it is easy to damage the material or spoil the edges of the sheet, violating the technology. Experienced craftsmen advise not to save on blades and cutting tool blades, as a blunt knife makes the cut uneven and sloppy. Cutting is carried out in the following sequence:

- First of all, the area where the sawing will be performed is cleared. To make the surface flat, on it spread sheets of plywood or particle board.

- Before cutting polycarbonate, the surface is marked with a marker and a long ruler.

- Under the sheet of plastic on both sides of the planned mowing line is placed wooden bars with a thickness of at least 40 mm. A wide board is also laid on top along the marking, to be used for driving.

- Straight cuts are performed with an angle grinder at low speed, and curved cuts with a jigsaw.

- When the work is finished, the chips from the surface of the material are blown off with compressed air.

Please note! Cellular plastic up to 6 mm thick can be cut by stacking several sheets on top of each other and placing plywood under them. In industrial conditions this material is processed using a laser, which is much faster and easier than using a hand tool.

Stationery knife

At home, polycarbonate can be cut with an ordinary office knife. Cellular laminates with a honeycomb structure are more commonly cut with this tool. Monolithic polycarbonate can not be cut with a knife, as it is too hard. To get an even cut, it is better to adhere to the following technology:

- To cut a sheet of polycarbonate plastic, you will need a high-quality, sharp office knife.

- Polycarbonate is cut with a box cutter in two steps: first you make a small cut to prevent the tool from slipping, and then you carefully finish cutting the material.

- A box cutter is used to cut polycarbonate sheets no thicker than 4-6 mm.

Please note that you use a stationary knife for making small cuts and fittings on plastic sheets, because it is too long and inconvenient to make long cuts with it. An ordinary office knife can quickly become blunt or break.

Tools

The very first tool that almost everyone has and with which you can work with polycarbonate. is an angle grinder. And. to use an expensive tool is not necessary at all: even an inexpensive and small angle grinder will perform all the work perfectly. To make even cuts, you need to install a wheel 125, designed for metal. the only thing to pay attention to is experience, because the tool is characterized by high revolutions, and if you have not worked with it before, it is advisable before you cut polycarbonate, to practice on scraps of this material. Where to get them? Turn to craftsmen who make polycarbonate structures.

A box cutter

Perfectly cuts the blades of polymer plastic and a stationery knife. over, even beginners can cope with it. The main thing is that the knife was of good quality, and the work was not done in a hurry. the blade of such tools is very sharp, and you can not only make the wrong cut, but also hurt yourself. The clerical knife is suitable for honeycomb sheets with thickness of 4-6mm, but it is already difficult enough to work with 8mm sheets. It is almost impossible to cut polycarbonate on thicker sheets, so experts recommend using a knife only where it is necessary to trim the material, and even then on sheets up to 10 mm.

Electric jigsaw

Household, the most common electric jigsaw is also quite suitable for working with polycarbonate sheets, only it is necessary to install a file with fine teeth, otherwise the material will tear, not cut. This tool, like the angle grinder, is easy enough to use, but to be fully confident in the quality of work, it is desirable to practice in advance. Electric jigsaw is very much in demand especially when you have to perform the cutting of monolithic polycarbonate of complex decorative forms or make curves.

On a note: If you have to perform cutting of thin sheets, the experts recommend folding the cloths by 10-12 pieces, and then put a layer of cardboard under them, and then cut all at once.

When it is necessary to perform the cutting of only one sheet. the risk of cracking increases significantly. To avoid damaging the material, you need to work only a very well sharpened tool. There are masters who, working with polycarbonate, use scissors. This is also quite acceptable. The main thing is that the tool used does not violate the structure of the blades.

Beginners are usually interested in: whether and how to cut cellular polycarbonate with a hacksaw, or a hand saw?In the case where there is no experience, it is advisable not to use these tools: the blades along the cuts may crack. It is better to work with power tools. But for beginners and experienced professionals alike, it is imperative that the polycarbonate sheets be secured well to prevent vibration and stress in the material, which is also fraught with bad consequences.

Laser cutting

In addition to the methods listed above, you can also cut with a laser. But, to work with a laser machine you need to have the appropriate skills. In addition, not every master has such a tool, so laser cutting polycarbonate is available only to those who deal with polycarbonate professionally. But if there is an opportunity to perform work with a laser, it is necessary to use it, because it guarantees:

- high speed of work;

- no defects;

- Excellent quality of cutting;

- Cutting accuracy: when working with a laser size accuracy is observed to 0.05 mm;

- the sheets do not need to be fixed when working.

To the blades of monolithic polycarbonate, you can apply any cutting tool designed to work on metal or wood, even a standard metal cutter.

An electric jigsaw

This tool is very often used to cut polycarbonate. When working with a jigsaw, experts recommend adhering to certain rules, and then it will be the best tool for cutting monolithic polycarbonate:

- When sawing thin sheets, they must be placed on top of each other, lining the bottom with cardboard;

- use a saw with fine teeth;

- there is a risk of cracking when cutting a single sheet. In this case, the teeth of the saw should be perfectly sharpened, and the master must carefully monitor that the structure of the fibers of the material is not disturbed.

The choice of tool and cutting rules

Consider how and what is better to cut cellular polycarbonate and monolithic translucent polymer.

It is important that the tool does not spoil the material. for example, scissors for cutting plastic or construction scissors can not be used, they squeeze the cellular polycarbonate, deforming the edges of the cut.

Also contraindicated cutting tools with large teeth, including wood hacksaw. it rips the material, the cut is obtained uneven, with burrs and nicks

Be sure to read: How to join the sheets of polycarbonate with each other: 3 ways

- utility knife (assembly knife or stationery knife);

- with an angle grinder (angle grinder);

- circular saw;

- hacksaw for metal;

- electric jigsaw;

- laser.

The method of cutting is chosen based on the available tools, thickness and structure of the material.

Using a knife

To cut the polycarbonate a box cutter is used, the blade of which consists of breaking segments. The construction knife is also suitable, it is more convenient to use due to the ergonomic handle. You can also use a shoemaker knife.

For monolithic polycarbonate this tool is not suitable, because the material is too hard and the work requires a lot of time and effort

It is convenient to cut not more than 6-8 mm thick honeycomb plates with a knife.

Before cutting a panel, check the sharpness of the blade on unnecessary scraps. If necessary, sharpen the shoemaker knife or remove the blunt elements of the retractable blade. Use a rule or metal ruler to cut in a straight line on the mowing line. The blade of the knife should be at an angle to the surface. the thicker the material, the angle should be closer to the right.

Cutting polycarbonate with a knife

First make an incision at the end, then, without removing the blade from the notch, slowly guide it along the mowing line of the marking towards yourself. Roughness and occasional surplus fragments are removed after the element has been cut out of the board. If the polycarbonate material is not cut in one go, repeat the process in the same way. Overbend, break the sheet should not be allowed, otherwise its edges will be severely deformed

If you need to cut a large area, it is better to choose a tool that will provide a higher performance. In this case the knife is needed in any case, to remove burrs and trim irregularities, fitting the element of glass precisely to a given size.

Cutting with an angle grinder

To cut the polycarbonate with an angle grinder machine, use a wheel designed for cutting metal. Cut the panel with an angle grinder without fear of melting the edges of plastic material will help

- The use of a cutting wheel to work with aluminum (it is less heated by friction);

- Use an angle grinder with a speed regulator (the work should be carried out at low speeds, it also reduces the risk of burrs).

Be sure to read: Characteristics of polycarbonate: sheet width and thickness

Cutting disc for aluminum with a diameter of 125 mm

It is convenient to cut solid polycarbonate and honeycomb panels with the angle grinder, including curvilinear trajectory. When working, always use protective goggles to protect your eyes from flying chips

After turning on the power tool, wait until it reaches the desired rotational speed. Cut the sheet material by moving the angle grinder away from you along the cut line. When cutting the panel along the lintels, hold the tool so that the blade goes straight without touching the ribs.

Cutting polycarbonate with an angle grinder

When you have finished your work, check that your cuts are straight and remove any chips or dust that have entered the cells with a blower or vacuum cleaner.

Using a circular saw

Use a circular saw with a fine-toothed blade. use a blade designed for plastics or metal. To cut a monolithic or honeycomb panel follow the same principle as when working with an angle grinder. First allow the tool to gather momentum, then cut the panel raised with two planks while moving the tool away from you. Press the base plate of the tool to the sheet. this will help cut the material more accurately along the outlined contour

Using a circular saw

Using a hacksaw for metal

Hacksaw, equipped with a blade with fine, frequent teeth, will help cut a straight strip of polycarbonate, cut the sheet lengthwise or crosswise. Elements of complex outlines cannot be cut with this tool

Metal hacksaw When planning to cut polycarbonate at home with a hacksaw, pay attention to the following point: in order to cut the line as evenly as possible, it is necessary to firmly fix the panel. The use of clamps and planks is recommended. The blade of the hacksaw is at an angle of about 30 degrees. Saw the panel toward you.

With a hacksaw, you can cut polycarbonate for a greenhouse with a pitched roof, as the tool cuts the material only in a straight line. Cut semi-circular end elements of arched designs will help jigsaw.

The use of a hacksaw for metal is acceptable for short cutting lengths. For a long cut, use a fine-toothed wood saw.

Hacksaw for wood

Cutting with an electric jigsaw

The most suitable tool for cutting polycarbonate into complex shaped elements is an electric jigsaw. The tool, equipped with a fine saw, is safer and more convenient to work in comparison with an angle grinder and a circular saw, while the speed and labor intensity of cutting significantly differs for the better in comparison with the work with a knife. It is allowed to cut polycarbonate monolithic and cellular polycarbonate with the jigsaw.

Using a jigsaw for cutting

Pay attention to the shape of the teeth when choosing a saw. Split teeth are designed for wood, they will tear polycarbonate, making the edges of the cut defective. To make cuts with straight edges without burrs and cracks, use a saw with fine straight or wavy teeth

Be sure to read: How to fix polycarbonate to metal: how to fix and which side

For cutting a monolith or a honeycomb panel of polycarbonate is ideal for metal, plexiglass or plastic saw with TPI (number of teeth per inch length) not less than 9. It is best. from 13 and above. The more teeth, the better the cut

Acrylic saw for working with polycarbonate For work it is required to use a sharp new blade. It must be properly secured in the tool and adjusted, otherwise the material will be cut with a lot of burrs and nicks on the edges.

- Connect the jigsaw to the powerpack and move it to the place where you want to cut on the edge of the sheet. It should be notched with a sharp knife beforehand.

- The base plate of the power tool is lowered onto the sheet and pressed down. When doing this, you must not put too much pressure, deflecting the material. It is recommended to preliminarily fix the panel to be cut with clamps or invite helpers to fix the polycarbonate, to dampen its vibration during the cutting.

- Turn the jigsaw on, let the saw gain the necessary speed. Then gently guide the tool away from yourself along the cut line. It is important to proceed slowly, paying particular attention to cutting the panel in curved areas. It is recommended to practice in advance on unnecessary material to make curved cuts confidently.

- When finished cutting, turn the tool off and unplug it from the power outlet. The cut element is cleaned of irregularities with a construction knife, swarf and dust are removed.

Laser cutting

Cutting of cellular polycarbonate and solid panels by laser requires high precision equipment. The advantages of the technology are minimal cutting error (not more than 0,5 mm) and perfect cut edges without burrs. The method is suitable for serial production of greenhouse glazing, as well as other construction and decorative elements made of translucent polymer. Working with laser equipment demands professionalism.

Laser cutting application