Do-it-yourself fracture from the tiller neva

Adapter for Tiller Neva

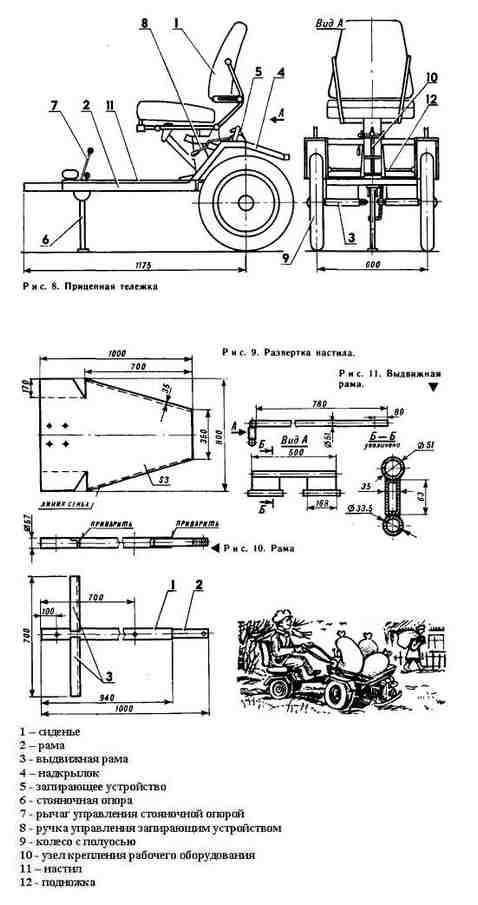

Drawings and dimensions for different tillers may vary depending on the design. So for the popular models of Neva, MTZ, OKA tillers, homemade adapters can differ significantly.

By making a homemade adapter to the tiller, using various types of attachments with it, you can not only facilitate the work, but also significantly increase productivity.

Required tools and materials

With your own hands and even without assistance, you can make a manual adapter or a dump adapter. Therefore, first of all, it is necessary to decide on the type of additional equipment. The next stage is the drawings. You can use ready-made ones, based on the instructions for the tillers of the same brand, but already implemented with adapters, or you can create it yourself. When making drawings with your own hands, careful attention should be paid to the main elements:

- steering wheel control:

- frame;

- seat;

- frame;

- adapter portal;

- suspension;

- coupling mechanism.

When the diagram is ready, you need to take care of having the following tools at hand:

- welding machine;

- drill;

- Grinder;

- two wheels with an axle;

- lathe;

- a ready-made chair of a suitable size;

- metal profile for the frame;

- steel corner and beams;

- fasteners;

- bolts, screws;

- screwdriver;

- control levers;

- circle made of steel with special holes. the basis for adhesion;

- bearings;

- lubricants and primers for finished structures.

Varieties of adapters for tiller

Externally, the adapter looks like a two-wheeled trailer with a driver’s seat. When installing such a trailer, almost all work performed is automated. The tiller itself becomes practically a mini-tractor. In addition, several models have a dedicated lever that allows you to raise and lower the seat, making your work even more comfortable.

Tiller adapters can be of several types. To make the unit yourself, you need to decide which type will be more convenient and comfortable for the owner. Depending on the type of clutch, they come with a steering and a movable joint. Depending on how the main power plant is located, there are two types: front and rear adapters.

You can also read about how to make a tiller trailer yourself.

How to make an adapter to the tiller with your own hands

Drawings of key adapter assemblies

Coupling mechanism. It looks like a welded structure inserted into the main frame and bolted to it. Consists of two pieces of square pipe welded onto each other and a piece of regular “water” pipe with a gauge of 1.1.5 inches.

In the pipe, not fully inserted, clamped by a bolt, a stem with a welded on homemade tee. The stem is lubricated with grease and allows the tee to rotate along the axis, to provide a rolling effect when moving on uneven ground.

Wheel attachment assembly. The structure consists of two perpendicularly welded pipe sections. The horizontal section is inserted into the fixing pipe and bolted together. On the vertical part, an axle with a wheel is fixed (on bearings).

Other nodes of the adapter are not so important, and we will not consider them.

How to make an adapter to the tiller with your own hands

It is not difficult to create a homemade adapter for a tiller with your own hands, it will take time, desire and a small amount of money.

Flexible joint adapter

With a movable joint, the angle relative to the vertical axis between the adapter and the tiller changes. It is much easier to make such a trailer, but more effort will be required when making a turn. However, this type of adapter is inferior in geometry: the turning radius, as well as its angle, is much larger.

Mini tractor from Tiller Salyut

Salut products are equipped with engines of BriggsStratton, Kohler Courage, Honda and others. The power of the units is 6-7.5 hp. The units are equipped with a mechanical two-speed gearbox with reverse and an additional reduction gear. The torque is transmitted by a V-belt transmission to a mechanical gearbox connected to the driving axle shafts. The kinematic system uses two belts, which reduces the risk of slipping under load, increases the service life and the transmitted torque.

Due to the peculiarities of the transmission, Salutes are often used as raw materials for the construction of tractors with a drive on two or four wheels. Before converting the tiller into a mini tractor with his own hands, the owner can purchase a ready-made set of parts for conversion.

- widen the front axle track up to 1200 mm (to improve stability);

- increase the track of the rear base axle by installing homemade or factory axle shafts;

- use standard tires as driving wheels.

Mintractor from Tiller Neva

Equipment under the Neva brand is equipped with a number of engines developing 5.5-10 hp. Engines are equipped with gearboxes with two or four gears (plus reverse). The drive of the wheels is carried out from the reducer of the combined circuit (gears and chain). For a homemade tractor from the “Neva” tiller, it is preferable to use models with a powerful engine.

In the design diagram of the Neva tillers there is a standard hitch, which is designed for hitching a plow, harrow and other agricultural devices. The hitch is transferred to the homemade tractor without changes. The construction of tractors on the basis of the “Neva” is carried out according to the drawings, which were published in periodicals.

Among the designs created by hand, there is a scheme based on the borrowed front suspension and steering rack from the Oka subcompact car. For the manufacture of the rear axle, a node from the Niva is used.

Design features

Converting a tiller into a mini tractor does not require the owner to complete technical documentation and register the vehicle with the traffic police. A common feature for self-made structures is a frame on which the power unit, rear axle and control units are rigidly mounted. When assembling the tractor, ready-made units from serial cars and tractors are used.

For those who want to save time, ready-made kits for converting a tiller into a mini tractor are available.

An example is the conversion kit for Crosser vehicles with medium.

There are more affordable kits that are made by small workshops. The kits include a frame, actuators and brake mechanism, fenders, as well as a seat and steering linkage. The advantage of this set is its versatility. the buyer modifies it for the available tiller in accordance with his preferences.

As power units, four-stroke carburetor engines with a cylinder volume of up to 250 cm³ and developing up to 10-13 hp are used as standard. Diesel engines with similar characteristics are less common. The gearboxes have up to four speeds and are connected to the drive wheels by a belt drive. Gear or chain reducers are used in the wheel drive. Stock transmissions often lack a differential.

An additional pair of wheels installed on the minitractor can be used to control the direction of travel. In theory, it could be equipped with a drive, but the drivetrain would get more complicated. All-wheel drive requires the use of constant velocity joints on the steered wheels and a differential. Otherwise, the four-wheel drive will impair the passability and reduce the reliability of the transmission.

Depending on the purpose of the minitractor, a frame scheme is selected. If the tractor is used for row-crop or other agricultural work, then a closed rectangular frame made of steel profile will be optimal. The frame must have sufficient strength and withstand the weight of the tractor mechanisms, as well as the loads arising during operation.

If the minitractor is supposed to be used as a means of transportation, then the use of a broken frame, consisting of two parts, is recommended. The frame elements are interconnected by a hinge joint. The complexity of creating such a design is the transmission. To transmit torque to the drive wheels, you will have to use a propeller shaft or place the engine together with the drive wheels on one part of the frame. The second option is simpler, but does not provide uniform loading of the tractor wheels.

It is possible to install crossbars for rear hitching of auxiliary agricultural equipment. For towing trailers, ready-made adapters or self-made units are used, created taking into account the characteristics of the trailer.

Min tractor from Tiller MTZ

When building a tractor based on the MTZ tiller, a powerful frame made of a steel square section is used. The wheels and engine are covered with homemade sheet steel hoods. It is recommended to cover the cab floor with a rubber sheet, which will protect the metal from damage and premature corrosion. A feature of the designs of tractors based on MTZ equipment is the possibility of reverse conversion.

In the scheme of a heavy home-made tractor, a hydraulic drive of auxiliary mechanisms (plow or blade) is used. The hydraulics are constantly driven by a gear pump, which is driven by a separate belt from a pulley located on the extended output shaft of the gearbox. The hydraulic drive is controlled via a spool valve. It is possible to use a hydraulic cylinder in the steering system, which facilitates the rotation of the steering wheel.

The size and power of the engine allows the installation of a car generator that will work in conjunction with the battery. In this case, the tractor is equipped with external lighting equipment (headlights, direction indicators, dimensions), and you can operate it at night.

Minitractor from Tiller Centaur

The most reliable and practical home-made tractors are designs created on the basis of professional or semi-professional tractors. Products have a high cost, which pays off with a resource and versatility.

The advantage of a tractor based on the Tiller Centaur is a diesel engine with a power of up to 9 hp. The engine is mounted in front of a homemade frame. The frame is assembled from scraps of channel bars or corners. To transfer torque to the rear drive wheels, a belt or gear transmission is used. The rotating elements of the kinematic chain should be covered with protective covers, which will prevent the operator’s clothing from being pulled in during operation.

Since the diesel engine is heavy, pay attention to the weight distribution of the tractor. If it is necessary to tow trailers, it is recommended to increase the load on the rear drive wheels. The front axle is not equipped with a suspension and is rotary. For the control mechanism, gearboxes from cars are used. When operating at full load, the axle must have reliable contact with the road, otherwise the tractor will be uncontrollable.

The brake mechanisms are shoe or band type with a mechanical drive, located on the output shaft of the engine or on the driving axle shafts. It is recommended to equip the operator’s workplace with a soft seat with an adjustable shock absorption system (from tractors or trucks). This solution will improve the working conditions of the driver, since the homemade tractor has no suspension.

Mintractor from Tiller Bison

Chinese tillers Bison are equipped with gasoline and diesel engines of various capacities. For the construction of a tractor, diesel heavy tillers are recommended, which are equipped with a liquid cooling system. Due to this, the tractor will be able to work for a long time in conditions of high ambient temperatures.

To make a tractor from a tiller with your own hands, you need to make a frame from a steel corner of 50 mm. On the front of the frame there are cross members for mounting the engine. The frame is additionally reinforced with cross members and jibs, which increase torsional rigidity.

The motor is rigidly mounted to the frame, therefore fatigue cracks may occur under the mounting points. The torque from the engine is transmitted by a pair of belts to the gearbox located above the rear axle. The working area of the belts is covered with a metal shield (to protect the operator’s left leg) and a crossbar (to protect the hand from injury).

The steering gear from the “classic” VAZ models is mounted on a bracket next to the pedal assembly. Serial parts of steering mechanisms of domestic and imported cars are used for the swing mechanism.

Mechanical band brakes are used for stopping. The drums are made of steel cylindrical billets (for example, old gas cylinders). Installation of levers and pedals is done on bushings located on the frame. Brake actuators are adjustable in length to compensate for pad wear and varying braking intensity.

Min tractor from Tiller Agro

When building a tractor based on Agro, it is necessary to take into account the low fracture strength of the standard axle. Cases of axle breakage during the operation of the tiller without additional weight have been noted, and with an increased load, the risk of destruction of the unit increases. To reduce the risk of breakage, modernized wheel gears are used (from UAZ or LuAZ vehicles). When installing gearboxes, it is possible to change the gear ratio, which allows you to increase the traction range.

Before you make a homemade tractor, you need to decide on the location of the engine: front or rear.

The construction process is as follows:

- Make a frame and a front axle from metal profiles according to drawings.

- Fasten the wheel hubs to the front axle blank. The hubs are equipped with mechanically or hydraulically actuated brakes.

- Mount the axle. If a split frame is used, the axle is rigidly attached to the front half. The whole part of the frame is tilted for turning.

- Install the steering gear on the frame and connect it with the steering linkage to the steering knuckles.

- Install the steering column and check the operation of the controls.

- Place the rear axle in its original place. It is attached to the frame with two bearing races. There is a pulley on the axle for transmitting torque from the engine.

- Reinstall the engine and wheels.

- Position the operator’s seat and foot switch according to the drawings.

- Adjust the operation of tractor units.

Mini tractor from Tiller Cascade

Homemade tractors based on the Cascade are structurally little different from the rest. The engine is located at the front of the frame and drives the rear axle wheels. In the design of the rear axle, a gearbox and shortened stockings from the axle of the rear-wheel drive VAZ or Moskvich models can be used. The rear axle retains the standard main pair and differential. By shortening the stocking, the track is reduced to the required parameters. The stockings are fitted with standard hubs and rims with tires from the specified vehicles.

To control the tractor from the Cascade motor-cultivator, a rotary front beam is used, built on the basis of the crosspieces of the PAZ bus. Swivel hubs and steering gear are taken from VAZ vehicles.

The engine transmits torque through a belt drive to a four-speed gearbox borrowed from a Zhiguli (it is possible to use gearboxes from a Muscovite). The box is connected to the rear axle by a short propeller shaft. The disadvantage of this scheme is the increased weight and low cross-country ability of the tractor on soggy soil.

Do-it-yourself fracture mini-tractor: create an assistant

Making a homemade mini tractor

First you need to figure out exactly what a mini tractor is. This is a conventional tractor, which is constructed on the basis of a tiller. They come in 3 types: completely homemade, reworked with factory tools and manufactured at the factory.

Mini tractor based on tiller “Zubr

If you have a high-power diesel engine with a Zubr tiller, you can do it yourself into a mini tractor. You must also have the appropriate tools, assembly instructions, photos (diagrams) and the following parts:

- frame;

- brake system (cylinder);

Bryson Tiller. Exchange

- footrests on which the pedals are placed;

- steering column with rods;

- front beam (assembly includes brake discs and hubs);

- rear fenders;

- hitch with manual lifting mechanism, assembled;

- wheels that will be installed in front (suitable from a Zhiguli car or other tillers).

Suitable tools include: hammer, drill, wrenches, welding machine.

Having collected all the above details with your own hands, you will get a homemade fracture mini-tractor from a tiller.

The basics of the technology of self-assembly of a mini tractor

The natural primary task will be a clear layout of the alteration itself, the need to install specific equipment for the shed, for example, a mower, a tiller plow or a blade for a blade, is being considered.

Briefly, the process of breaking a tractor with your own hands can be described as follows. we place the tiller on a frame that was previously equipped for this purpose and made by hand. The brake system is based on a drum type and the steering rack can be used from Zhiguli.

Below you can see a selection of photos of self-assembly of the tractor.

tiller “Neva”. the basis of a homemade mini tractor

If you decide to take the Neva tiller as the basis of your tractor, then be sure to choose it together with the coupling, and it does not matter whether it is factory installed or it was designed by hand. This will make it possible in the future to engage in the transportation of goods by hitching a trailer with a body. The comfort and convenience of the model will add attributes such as a steering wheel from a car, a car seat and pedals.

Of course, you can choose any tiller for the purpose of making a homemade mini-tractor, but it is still better to choose the Neva units. This is due to the fact that they are more reliable and powerful, and their volume can reach 8.5 liters. These properties guarantee that the mini tractor will be made with the least number of modifications.

The next step will be the manufacture of a dump adapter, which is quite simple to make, just having the necessary material, electric welding and an angle grinder. The trailer can be tilted and rotated, as it is provided by a special system of the frame fastening structure itself. The controls in the tiller are duplicated, which allows you to use the tiller as a separate unit, having previously disassembled the homemade mini tractor.

The practicality of this design makes it possible to operate a mini tractor for transporting not only building material (bricks), but also interact with loose soil components. The loader, which is designed for dumping and was installed earlier, makes it possible to dump soil to any place without limiting the choice.

To your attention a selection of high-quality video material on homemade mini tractors.

How to self-assemble a tractor from a Centaur brand tiller

Naturally, the most durable, reliable and powerful version of the fracture tractor will be the model, the design of which was based on a professional or semi-professional trailer. Thanks to their use, the performance of the device and the resource of use increase.

One of the optimal types of such units is the Centaur tiller, whose diesel engine power reaches 9 hp. Of course, the decisive factor when choosing components, such as a tiller, will be the purpose and functions assigned to the tractor.

It is necessary to think in detail about the body structure, how it will be connected to the engine block. The body and frame are made using profiled pipes, and metal corners can also be used. When installing a powerful engine, the body can be made from a small trailer to a car or motor vehicle, only you need to take into account in advance how it will be attached to the tiller.