How to cut tiles diagonally

Cutting tiles with a manual tile cutter

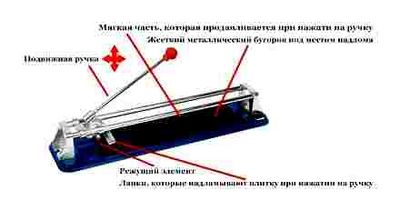

How a manual tile cutter works

- The tile is inserted into the tile cutter, and the markings on it are aligned with a special mark.

- The handle is lowered and held away from you. It must be driven at the same speed and even pressure so that the roller cuts the glaze to the same depth. It will be enough to run the roller once. If you drive several times, the breakage may turn out to be of poor quality.

- Next to the roller there are special paws that lower and break the tiles into 2 parts, after a sharp push on the lever. In this case, all tile cutters have a metal tubercle on their platform, and soft pads along the edges. When you press on the edges of the tile with your paws, maximum stress will be created at the notch, if correctly aligned with the backing, and it will evenly break off.

It is difficult to explain this in words, so it is easier to watch a video that shows how to cut tiles correctly with a tile cutter:

3 ways to cut tiles at home

Any process of laying ceramic tiles is not complete without cutting it. There will be a lot of it especially if you use some kind of non-standard layout, for example, diagonally. In the last article, we talked about which layout is better to choose in order to get uniform and beautiful cuts everywhere. Now we will talk about how to properly cut tiles at home.

As you know, the tile is made of baked clay, which is covered with glaze on top. It’s hard to break it with your hands, but if it lies on any unevenness, then it easily cracks from a small load. To simplify this process and make the required break line, you need to loosen the top layer of the glaze. that is, cut it, and therefore make efforts to break.

There are 3 main ways to do this:

- Special tool. manual, electric tile cutter or special tongs.

- Angle Grinder.

- Other handy sharp tools.

Easy way to Measure and mark ceramic tile for diagonal and diamond pattern cuts

Let’s talk in more detail about each tile cutting method.

Fast navigation through the article

How to choose the right disc by tile

For cutting, metal discs are used with diamond dusting along its edges. But they are different: for concrete, brick, stone. Tiled discs do not have any holes, the soldering on them is uniform and smooth. Discs for concrete have slots on the solder, and will chip when vibrated. If you cut ceramic tiles with them, then these chips can fly into the face.

Electric tile cutter

If you have a large amount of work, then the fastest and highest quality cut comes from an electric tile cutter. They use a diamond wheel and supply water to the cutting site to cool and remove dust. The cheapest types of amateur class can be found on sale for 3-4 thousand rubles.

How to cut tiles without a tile cutter

If you only need to cut a few tiles, it doesn’t have to be spent on a tile cutter. You can use the tools at hand:

- Glass cutter.

- Drill. It should preferably be with a victorious tip, as it will scratch the tile better.

- Nail.

- Construction knife.

Attach a metal ruler to the notch and draw once with a glass cutter or drill. A deep scratch should remain on the enamel. If you use a knife, but you will need to carry out several times.

Place the tile with the cut at the corner and press down on its edges with a sharp motion. The cut will not turn out perfectly even, unlike the tile cutter, but you will not have to spend additional money.

To make cutting ceramic tiles easier, many craftsmen soak them in water for about 1 hour.

We make a drink at 45 degrees

Ceramic pencil skirting is best for protecting the sharp outer corners of tiles

If you are using a professional electric tile cutter, the tilting platform there makes it easy to make a 45-degree angle on the tile bevel, but not everyone has such a tool. It is easy to make such an angle on your own using the same angle grinder “by eye”. The disc is guided along the line of the cut, with the disc tilted slightly inward.

Undercut tiles at 45 degrees

Tile cutter tongs

The tile cutter-tongs are the cheapest (200-400 rubles), and it is suitable only for small volumes of work with thin ceramic tiles at home.

After notching, press down on the tile with a cracking pliers

- Make markings taking into account all gaps and seams (-5 mm).

- Attach a metal ruler to the mowing line and run the cutter along the line once. The pressure should be moderate to form a visible streak. Lead him from the far end to you.

- Place the tongs with their feet along the mowing line of the crowbar near the edge. The sponges should be on top of the glaze and the straight part on the bottom. the line of the break should go right in the middle between the edges of the upper jaw.

- Press gently on the handles to break off the tiles. At the same time, do not raise it high, otherwise after falling it will break.

Cut off the plate without chips

Porcelain stoneware belongs to the materials of increased strength. There are practically no pores in it, it does not absorb water and does not crumble. It is very difficult to even scratch it. Therefore, home craftsmen have the question of how to cut off porcelain stoneware without chips and is it possible at all. It must be admitted that theoretically it is possible, but in practice it turns out very rarely. often, small chips remain on the cut, which have to be sanded.

To keep them as small as possible, experienced craftsmen advise following these recommendations:

- Cut the part from the top side. Most material chips appear where the cutter exits the plate.

- The smaller the thickness of the selected cutting disc for the grinder, the lower the likelihood of chipping.

- Reduce torch speed at the beginning and end of the cut line.

- When working with a mechanical tile cutter, apply more pressure to the lever than when cutting a regular tile.

- Make a cut slightly to the right of the intended mowing line so that it remains on the cut piece. Then it will be possible to remove unwanted chips with a sander.

It is very important that the tool is of high quality and suitable for the selected material. Otherwise, it is almost impossible to get a beautiful cut without chips. If, nevertheless, they appear, which happens most often, the defects should be sanded down. You can use sandpaper or a diamond sponge.

The best option is a grinder with a special attachment. This is the so-called turtle or flexible diamond circle. They are distinguished by the diameter of the particles deposited on the surface of the diamond coating. The turtle can only work with a grinder, the model of which provides for the ability to regulate the number of revolutions. If it is higher than three thousand per minute, the nozzle may fly off the axis.

Tools for cutting porcelain stoneware

Before determining how and how to cut porcelain stoneware at home, it is worth understanding its features. It is a composite material that successfully combines the properties of natural stone and ceramics. It is made by pressing a mixture pre-fired at high temperatures. The result is a highly durable and wear-resistant material. In the production process, it can be given a wide variety of colors and textures.

The surface of ceramics can be matte, glossy, structured, etc. Consider this when choosing a cutting method.

You can cut a fragment of a tile using various tools:

- glass cutter;

- electric tile cutter (aka wet cutter);

- mechanical tile cutter;

- Angle Grinder;

- waterjet cutting attachment.

The latter method is not used in a home workshop, since it is assumed that special expensive equipment is available.

How to cut porcelain stoneware with a glass cutter

This is the easiest tool to use. It also gives a minimal effect. Using a glass cutter, you can cut off porcelain stoneware, but provided that its thickness is small. This is how the wall cladding is most often cut. Glass cutter will not cope with floor tiles.

There are two types of tools: with a hard metal roller and with a diamond cutter. The latter option cuts better, but breaks down faster. Its cost is higher than that of a roller analogue.

With a glass cutter, you can make a straight or figured cut. In the latter case, you will also need special nippers. To cut the tiles in a straight line with the mowing line, proceed as follows:

- We lay the cladding on a flat base. Determine where the cut line will go.

- We take a ruler, lay it along the future cutting line of the cut and press it with our fingers.

- Gently, but with strong pressure, draw the line along the ruler with the tool. We try to scratch a deep enough groove at a time. Otherwise, chips cannot be avoided.

- We put the part on the edge of the table or workbench and press firmly on its edge. So that the liner splits along the intended mowing line.

- Grind the edge if necessary.

If you want to make a curved cut, a line is drawn with a glass cutter. Then you need to take pliers and use them to remove sections of the tile. The closer the cut is to the mowing line, the smaller the pieces should be cut off. The edge with such processing will turn out to be sharp and not entirely even, so it must be sanded.

How and what to cut porcelain stoneware at home: 4 proven methods

How to cut a porcelain stoneware angle grinder without chips

Almost every home craftsman has an angle grinder, or an angle grinder. Therefore, it is she who is most often cut porcelain stoneware. Unfortunately, it is almost impossible to make such a cut without chips, but it is quite possible to minimize their number. For this, it is very important to choose the right disc. He must have:

- high-quality diamond dusting;

- marking confirming that the device is intended for cutting porcelain stoneware;

- the minimum possible thickness;

- continuous cutting edge.

An angle grinder is a potentially dangerous tool, so safety rules should not be neglected. You should take care of the means of protection. The kit includes:

- Respirator, as a lot of dust is generated when cutting.

- Safety goggles to prevent possible exposure of disc fragments to the eyes.

- Special clothing.

- Earplugs or ear muffs to protect your hearing from loud noise.

It is not recommended to neglect protective equipment, even if it is planned to cut several plates.

Cutting porcelain stoneware tiles correctly with an angle grinder is quite simple if you follow the instructions:

- Preparing a place to work. Lay a substrate on the leveled surface, which will protect the base. You can choose penoplex, polystyrene, etc.

- We put the part on the base with the front side up, mark the section of the cut on it. So that there are fewer chips, we glue a strip of masking tape on it, draw a cutting line along it.

- We put a metal corner on top of the tile along the cut path, fix it with clamps. This will allow you to make an accurate cut. This must be done when cutting products with a large thickness.

- We start the angle grinder. We cut the part at a time, direct it “away from ourselves.” To get an even edge, cut off the fragment so that the line of the marking remains on the product. It will be removed during the sanding process, and the tile will retain the specified size.

- We remove the masking tape, if necessary, we grind the end of the part.

If the plate is thin or you don’t need a perfectly straight cut, you can make your job easier. The angle grinder does not make a cut, but only a cut. Then the fragment is broken off with a sharp strong movement.

It is very convenient to use a grinder to cut porcelain stoneware tiles. First of all, because it is the most affordable of all the devices that can be used. They can make cuts of various shapes, including any curved. However, the angle grinder is traumatic, you need to work very carefully. It is very dusty and noisy.

How to cut porcelain stoneware with a tile cutter

The principle of operation of the tool is somewhat similar to the glass cutter. There, too, there is a cutting roller that moves along the guides. In addition to it, there is a bed on which the part is laid, a lever and guides. It is very important that the diameter of the cutting element matches the height of the tile.

In addition, when choosing a device, pay attention to:

- The base of the device. The metal from which it is made must be thick enough so that the base does not vibrate or bend during the cutting process.

- Strength of guides and supports.

- Smooth movement of the carriage. It is desirable that this is ensured by special bearings.

- No backlash when advancing the carriage. If it is available, it is impossible to make a straight cut.

Tile cutters vary in length and it is best to choose a long model. This will make it possible to cut porcelain stoneware of different sizes, not only along the side, but also diagonally.

To cut a piece of porcelain stoneware tiles with your own hands along a straight mowing line, you need to follow these steps:

- We put the tile cutter on a solid, even base.

- On the product we outline the line of the cut.

- We lay the part on the bed so that the trajectory of the roller goes exactly along the basting.

- We make an incision by pressing on the carriage and moving it away from us.

- We release the handle and break the part with strong pressure.

- We grind the cut to remove possible chips.

Working with a mechanical tile cutter is very simple, even a novice master can handle it. There are, however, some disadvantages to be aware of:

- A fragment already 6 mm wide cannot be cut in this way.

- It is also impossible to chamfer or make a curved cut with a mechanical tile cutter.

- If the cut falls on the edge under the glue or the surface of the material is ribbed, there is a very high probability of chipping.

How to cut porcelain stoneware with an electric tile cutter

In the recommendations on how to cut porcelain stoneware tiles at home, you can read that it is convenient to do it with a wet cutter. This is the name of an electric type tile cutter, for which a diamond cutting disc is used. To cool it down, water is supplied to the part during the cutting process (hence the name of the device).

There are two types of equipment: with the upper and with the lower supply of tiles. The first ones make the cut as accurately as possible and are more expensive. For household work, budget devices are more often purchased that feed parts from the bottom.

Devices of any type make it possible to make cuts not only straight, but also curved. To cut a piece of porcelain stoneware tiles, do the following:

- We outline the cutting line.

- We fix the part on the bed using special clamps. If you have to make a curved incision, you will have to hold it with your hands.

- We start the device. First, we select the minimum speed of the disk, so the part does not deform.

- Increase the cutting speed gradually. Make sure that the element does not move from vibration.

An important point. The product should be stacked so that the cutter starts to cut its front side. That is, on equipment with an upper cutter, the part is laid face up. On a bottom disc appliance, place the tiles face down.

Cuts made with such equipment are more accurate and better than with a mechanical device. It is especially appreciated by beginners, as it is able to completely neutralize the so-called shaking hand factor. In addition, the device allows you to cut fragments less than 6 mm wide, does not generate dust or noise. The main disadvantage of the device is the high price of quality models.

Working with a glass cutter

The simplest, cheapest and lightest tool for processing ceramic products is a glass cutter. It can be of two types: with a small diameter roller and with a diamond tip. There are practically no special differences in work between them, however, the first tool is more convenient to use. In addition, cutting tiles with a glass cutter is no different from cutting glass.

Let’s take a look at the step-by-step instructions for working with this tool:

- firstly, before cutting the tile with a glass cutter, you need to accurately mark the cut line with an erasable marker or pencil on its glossy side. For this, it is also advisable to use corners or metal rulers. With a ruler on the mowing line, you need to run the glass cutter only once from the far edge of the ceramic to you. over, trying to distribute the force as evenly as possible when pressing the tool. Thus, you will get an absolutely flat line. a depression that weakening the strength of the canvas.

- secondly, you need to position the tiles on the table so that the line of the notch on the product and the edge of the table completely coincide. Further, gently holding part of the tile on the table, you need to press on its other edge: the product will break gently and precisely. The edges after all work can be sanded.

How to properly cut ceramic tiles: 4 ways

Ceramic tiles are a very durable and attractive facing material in all respects. However, the tiling process is not as easy as it sounds and requires patience and preparation. In order to successfully install this material on the floor, on the wall, around the edges of the room, around electrical appliances, window frames, pipes or various protrusions, it is necessary to use specialized equipment. However, before starting directly to work, you will definitely need to decide how and how to cut ceramic tiles.

- 1. Tool for cutting ceramics

- 2. Working with a glass cutter

- 3. How to cut with a manual tile cutter?

- 4. How to cut tiles with an electric tile cutter?

- 5. We cut ceramics angle grinder

How to cut tiles with an electric tile cutter?

If you plan to work with very hard and large-format tiles, then it is best to use professional equipment. an electric tile cutter. To work with such equipment, certain professional skills and abilities are required. In particular, since the cutting process is rather complicated and time consuming. However, nevertheless, if you are interested in how to cut ceramic tiles as quickly and accurately as possible, even with very large volumes, then an electric tool is the best choice. Such equipment is quite expensive, but it pays off with repeated use and can serve for several decades. The design of the electric tile cutter is almost identical to the modern circular saw. The main differences are the discs used and the presence of water trays.

Another feature of these machines is the ability to carry out a neat bevel cut. This is very useful when cladding outside corners. In this case, the need for aluminum or plastic corners is completely eliminated. The product, which is docked in a corner with a 45-degree cut, looks very interesting.

We present to your attention a short instruction manual:

- pour water into the bath so that it overlaps the disc by 2-3 centimeters;

- we measure the part of the tile that needs to be cut off and put it on the machine;

- then we press our canvas to the machine and slowly bring it to the disk. It is not recommended to press hard on the disc, as it may stop;

- now you need to make a cut along the second mowing line. To do this, carefully lift the tile and do a similar procedure.

How to cut with a manual tile cutter?

This tool is only used for making light straight cuts. With it, you can cut the tiles either evenly or diagonally. In this case, the direction does not matter. This equipment is very easy to use. At the same time, before cutting a tile with a tile cutter, you must have a general idea of its structure. The tool is a base where special tubular runners are fixed. A carriage with a hard alloy roller slides over them. After marking, the tile is laid on this base in the required way.

Here are the basic guidelines for using this tool:

- it is necessary to apply a roller to the tile and make a neat cut using a special handle. In this case, only one cut is needed. Don’t cut the same spot two or three times. The result will be disastrous. the material will break completely in the wrong way. It is also because of this that you need to carefully monitor the sharpness of the cutting device. On specialized professional models, it is removable, so, if necessary, a dull roller can be easily changed.

- it is worth noting that in order to obtain high-quality tiles when working with such a tool, you also need to be able to correctly break the material. On the basis of the equipment, in the course of the cut, a small tubercle is provided, which raises the edge of the ceramic product clearly above the cut and then releases its ends. It is thanks to this that the tubercle, together with the slot on the tile, acts as a guide for breaking. In addition, the product also breaks with the help of a movable T-shaped heel, which is located in front of the roller. This heel must be set exactly in the middle of the cut so that when the lever is pressed, it presses on the blade. This tile cutter can also cut diagonally.

Ceramic Cutting Tool

The quality of the cladding will depend on how the ceramic material is processed. If you are interested in how you can cut ceramic tiles, then, first of all, pay attention to the following tools:

- manual tile cutter;

- glass cutter;

- electric tile cutter;

- Angle Grinder.

Using this equipment, you can perform both standard cutting operations and rather complex procedures. For example, cutting rectangular and circular holes, trimming edges. Each of these tools is used for a specific amount of work. In addition, it has its own functional features that must be taken into account when starting the process of processing ceramics.

How to properly cut ceramic tiles: 4 ways

We cut ceramics angle grinder

The angle grinder gives very great cutting opportunities. it can easily and accurately not only cut along even lines, but also make curly cuts. If desired, using an angle grinder, you can cut a beautiful round hole with a diameter of 70 mm in the tile. In order for practically no chips to remain on the glossy surface, it is necessary to use only a new diamond wheel and cut from the back of the product. Therefore, before you cut the tile with an angle grinder, you need to make sure the quality of the wheel and its functionality. We do the markings, trace the markings with the disk and break off the long part. Break off the rest. Corners can be smoothed with pliers or the same angle grinder.

An angle grinder equipped with a diamond disc is essentially a universal tile cutter. In order to increase the efficiency of the tool, the equipment can be equipped with a special cooling system. Of course, this increases the cost of the tool, but at the same time increases its productivity. It is thanks to its efficiency that the angle grinder has become quite widespread today.

The nuances of marking and calculations for diagonal masonry

For diagonal tiling, you need to draw up a drawing. If this is not necessary for simple styling, then for this option a beginner cannot do without a drawing.

It is very simple to make a diagram: draw a diagonal layout on a scale, then transfer the dimensions of the room to tracing paper and combine the two drawings, choosing the places for cutting the tiles as economically as possible. Fix this scheme and just make the calculation taking into account this alignment.

When calculating the material consumption, take into account that if the tile is not cut exactly in half, then it counts as one. Plus, when calculating, you should definitely add about 20 percent of the total amount of material in case of failure during pruning, transportation and for subsequent repair.

And one more small nuance that may not be known to a beginner: the heavier and thicker the tile, the greater the consumption of glue and grout material. Take this into consideration.

Why diagonally?

It is expensive to order diagonal tiling. It seems that the tiles are the same, and all the materials, and the floor or wall are no different, but more expensive. And not at all because it is much more difficult to do it. But simply because of the unusual request. The costs are mostly waiting for the owner because tile trims are difficult to use somewhere and there will be more of them than usual.

So why is it worth starting this type of masonry? Are there other reasons other than the striking look of the diagonal layout? The most important advantage is an excellent opportunity to divert attention from the flaws in the geometry of the room. Uneven walls, lack of parallels. all this can be skillfully hidden behind the diagonal layout. And even if you doubt your abilities, keep in mind that the flaws in laying tiles in a diagonal arrangement are almost invisible.

How easy it is to lay tiles diagonally if your arms don’t grow out of the right place

Laying tiles, in principle, is not an easy task, but diagonally. and even baffles many. Meanwhile, it is precisely this arrangement that looks especially impressive and allows you to break the space, expanding the boundaries and pushing the walls apart. Those who decide to do this for the first time and with their own hands should familiarize themselves with simple recommendations that will greatly simplify the work.

Laundry room part 6. Diagonal ceramic tile installation and measurement tricks

Read in the article

Preparing the substrate for diagonal tiling

Of course, the base for laying should be perfectly flat. To do this, remove the old coating, fill in all cracks and defects and grind the wall.

It is better to use a cord for marking. Marking can be made from corners or from the center of the surface. It is more convenient to mark from the corner in a small area, if you are not going to use tiles of different colors. When marking from the center, first determine the center point of the surface and then beat off the diagonal mowing lines, which will divide the right angles in half. In this case, the first tile is placed in the center of the intersection of the marking lines.

Masonry from the center is more convenient and easier, but you need to prepare for the fact that as you get closer to the edges, you will have to adjust your initial cutting plans, so do not rush to cut the tiles in advance.

Practice the styling process in this small

Laying tiles diagonally on the floor

Ceramic tiles can be laid on the floor in three main ways:

- seam to seam, in a straight line

- seam to seam, diagonal

- at a run

Of all of the above, diagonal tiling is the most beautiful, but at the same time, the most difficult way. The diagonal method of laying tiles creates a beautiful pattern on the floor, allows you to hide the non-parallelism and non-perpendicularity of existing walls, and visually expands the room. But tiles are more difficult to cut diagonally, and there may be a little more waste than when laying tiles in a straight line, or sparsely. So consider this fact when buying tiles.

Tiling work begins with the preparation of the substrate. The floor surface must be thoroughly cleaned of all “non-stone” and exfoliating materials, such as paint, linoleum, hardboard, bitumen, wood inserts. Prime highly absorbent and weak surfaces. Check the horizontal level of the surface with a long building level. With small differences of up to 2 centimeters, an experienced craftsman can lay the tiles perfectly even without first leveling the floor, but still, it would be better to first pour the screed over the beacons. Laying tiles on a perfectly flat floor is much easier and more correct, and it turns out more economically. The consumption of tile adhesive with this method is very small, and the dry mixture used to make the screed is much cheaper. When laying tiles in the bathroom, it may be necessary to waterproof the floor.

We lay out the tiles while without glue

Our screed is already ready, we proceed to laying the tiles. First you need to lay the tiles on the floor without gluing them. To do this, cut several tiles diagonally in exactly half. These triangular tiles are laid against the walls. The rest of the tiles are tightly, without distortions, seam in seam is applied to them. Choose the best location, do not be too lazy to rearrange all the tiles several times, try different options. Do not step on non-glued tiles, they may burst! In our example, we are laying tiles in a combined bathroom. We put whole tiles at the entrance to the room, while not whole tiles, the trimmed tiles will be hidden under the bathroom and behind the washbasin.

Now you need to prepare the tools. We will need: a container and a trowel for mixing tile glue, a bucket of clean water and a sponge for cleaning tiles and tools, a notched trowel, a level to check the horizontal and evenness of the tiles. You need to work with glue with rubber gloves. Have a few pairs ready, they break quickly. It is important to choose the right notched trowel. the size of the teeth must match the size of the tile. For floor tiles measuring 30 x 30 cm, a trowel with a notch size of 8 mm is suitable. Knead the tile adhesive according to the manufacturer’s recommendations. You should get a uniform mass, no lumps, not very liquid or thick. Remember to sweep the floor just before installation to remove dust that can reduce the bond strength between the tile and the adhesive. If the substrate is dry, it should be slightly moistened.

Apply glue to the floor with a comb

So, everything is ready, put on gloves and start laying the tiles. Spread the tile adhesive on the floor in an even layer, approximately equal to the height of the trowel teeth, holding the trowel at an acute angle to the floor. Then, lifting the handle of the trowel and firmly resting it on the floor, make uniform ridges of the glue. When the tile adhesive is prepared correctly, this is not a big deal. If the glue is too liquid, the combs will spread over the floor, if too thick, then the spatula will collect the glue and the combs will not work, moreover, the thick glue does not adhere well to the floor and tiles. Don’t be discouraged if the glue doesn’t work out the right thickness, just add water or dry glue and mix again. Try to keep the ridges the same height everywhere. Do not cover a large area with glue at once, as there is a chance that the glue will dry out before you have time to lay the tiles. Now start laying the tiles one at a time. Put the tile in the right place, press it to the floor, make several movements back and forth, as if rubbing it, move it to the right place. Pressing on different corners, achieve a strictly horizontal position of the upper surface of the tile. Check with a level in two mutually perpendicular directions. Before applying the level, it is recommended to wipe the surface from excess glue.

Laying tiles on glue, but a little dirty

Check the horizontal and evenness of the laying with the building level, it will never be superfluous and will allow you to notice and correct mistakes in time. Correct the position of the tile by rubbing with the force of the edge of the tile that you want to lower, the opposite edge will rise. If necessary, carefully remove the tiles, add more glue, or remove the excess and put it back. In order to maintain the same distance between the tiles, use plastic crosses to install the tiles of the appropriate size (we like the 1.5mm ones). They can be inserted both into the crosshairs of the seams, and two per seam, sticking in from above. If you insert crosses into the crosshairs of the seams, then when the glue dries, the cross may interfere with rubbing the seams, it is better to insert them from above, then they are easily pulled out. When a small area of the floor is laid out, finally level the tiles while they are still amenable to adjustment, usually about 20 to 40 minutes. Keep a bucket of water close at hand, and periodically wash the tiles with a well-wrung out sponge.

Washed tiles look beautiful!

It is better to lay all the whole and pre-prepared tiles first, so as not to be distracted by cutting the tiles. For example, one day put all the whole tiles in the center of the room, leaving corners along the walls, and the next day, first cut all the remaining tiles to size, and only then lay them on freshly made tile adhesive. In this case, do not forget to clean the floor and the ends of the extreme tiles from the glue that has come out, so that after hardening it does not interfere with laying the tiles further. This technique is even more convenient, because you do not have to spend time washing your hands from the glue to cut the tiles. It is not recommended to walk on the newly laid tile, so as not to move or push it. If there is an urgent need to step on the tiles, place pieces of plywood or chipboard on top to evenly distribute the load. When laying tiles on a comb, the next day you can walk on the laid floor. Do not forget to clean and rinse the tile joints from the glue on the day of installation, so that later they can be filled with colored grout.

Our laying floor tiles

This video shows how we lay tiles on the floor. The entire installation process is shown in detail with explanations.

How to cut ceramic tiles

When working with tiles, the question arises: what is the best way to cut ceramic tiles? The choice of tool is determined by the amount of work and the properties of the tile itself. There are several ways to cut ceramic tiles.

How to cut ceramic tiles

In any case, special tools will be needed for the work. The simplest of them is a glass cutter, a manual tile cutter has a higher performance, for professionals it is recommended to opt for electric tile cutters. Upon gaining a certain skill, the tile can be cut with an angle grinder, and a diamond string is used to make art products.

Other ceramic tile trimmers

What is the best way to cut ceramic tiles if you need non-standard edge shapes? There are various devices for this.

- Nippers. Used to bite off small pieces, corners and semicircles. Leaves an uneven edge that needs to be trimmed with an emery wheel.

- Diamond string. It is fixed in an ordinary hacksaw for metal, used for curly cut. It cuts only wall tiles and requires a certain skill, since during jerks, chips are formed on the surface.

- Crowns are used to make round holes in ceramic tiles for sockets and switches.

- Ballerina. With the help of such a drill, holes of various diameters are made. The size is adjusted manually by changing the distance to the cutter. Up to 20 cuts can be made with one nozzle.

How to cut ceramic tile angle grinder

New wheels are used for dry cutting, diamond dusting or for work on concrete. an angle grinder is best used with adjustable speeds. At a rotation speed of more than 3.5 thousand rpm, the tile cracks, and the dust content increases significantly.

The angle grinder can be used to cut floor tiles, porcelain stoneware and wall tiles. With a certain skill, you can cut circles 70 mm in diameter and make curly cuts.

The cut is made from the back of the tile, as small chips may remain on the surface. The canvas is placed on a solid and even surface, mark the fishing line with a marker, draw an angle grinder around it and break off the part that is longer. The cut surface can be trimmed with the same angle grinder.

Glass cutter

This is the simplest and cheapest ceramic tile cutting tool. It has a different design:

- cutting element. small diameter wheel;

- stylus with a diamond tip;

- roller glass cutter with oil reservoir in the handle. Grease flows down a narrow groove and facilitates notching.

Glass cutter cutting elements can be replaced as the edge is seamed. How to cut ceramic tiles with a glass cutter? On the front side, a cut line is drawn with a pencil or marker. Holding the ruler on the mowing line, draw a glass cutter in the direction from the far edge of the tile towards you. The goal is to draw a uniform depression that reduces the strength of the tile.

Then place the tiles on the edge of a table or other flat surface. the line of the cut should line up with the edge. Holding the edge of the tile on the table with one hand, with the other, gently press on the edge that is suspended. The tile should break at the notch. Its edges are sanded with a file for ceramic products.

It is advisable to use a glass cutter for small amounts of work. It allows you to make straight cuts vertically and diagonally. Not suitable for cutting floor tiles, porcelain stoneware tiles and tiles over 5 mm thick. It is problematic to cut a strip with a width of less than 20 mm with a glass cutter.

How to cut ceramic tiles with a manual tile cutter

The tool allows you to cut strips from 5 mm wide, straight or diagonally.

It is used to cut durable floor tiles and porcelain stoneware up to 15 mm thick. By design, it is a base, on which the runners of the carriage with a cutting wheel are fixed. It is slightly larger in diameter than in a glass cutter, which makes it possible to achieve a greater notch depth. The minimum size of the wheel is 1.5 cm.It is also removable, it can be replaced after a cycle of work.

On the base of the manual tile cutter there is a strip of solid material, with the help of which, after the cut, the tile is broken. There is a T-shaped piece in front of the roller on the carriage, which exerts pressure on the two halves of the tile.

The tile is placed on the base of the tool, after marking the break line, tightly clamped., The clamping corners must be metal in order to cut the floor tiles; plastic is enough for the wall. Pull the carriage handle towards themselves, making an incision on the front surface of the tile.

The incision is made once. After the end of the cut, the handle is pressed and the tile breaks. Edges will also have to be processed if they fall on a corner. If grout is used, then it will hide all defects.

We cut ceramic tiles with an electric tile cutter

This tool belongs to the professional category and is quite expensive. With its help, a significant amount of work is easily performed, it cuts any tile quickly, accurately and beautifully. Allows you to make a cut with a width of less than 5 mm, make cuts at an angle of 45 degrees, indentations and holes. It is used for curly cutting. The cut has smooth and slightly rounded edges. In some models, the edge of the blade is immersed in water, in others, the surface at the cutting site is only wetted. During operation, all dust settles in the cooling water tank.

In design, it is in many ways similar to a circular saw. Consists of a platform, a cutting disc fixed on it and an electric motor.

How to properly cut ceramic tiles with an electric tile cutter.

- Water is poured into the container so as to overlap the edge of the cutting wheel by 2-3 cm.

- Include tile cutter.

- Press the ceramic tile against the machine and slowly move it under the disc, focusing on the marked line.

- The blade is moved under the cutting element with a force depending on the strength of the tile. It is not recommended to apply excessive pressure on the knife, this may cause the tile cutter to stop.

- To cut a corner, the tile is gently lifted, unfolded and repeated.

It is necessary to monitor the condition of the cutting edge of the disc, replace it in time. Diamond wheels are commonly used. Also, regularly, as it gets dirty, they change the water in the bath.