How to evenly cut the corner of the ceiling plinth

How to cut coving corners perfectly

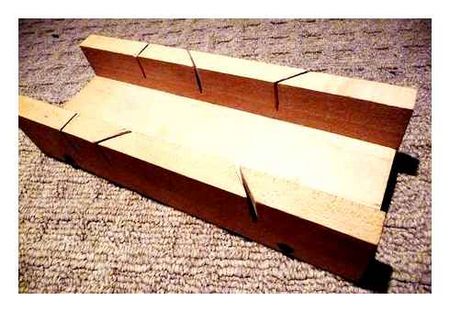

How to make a cross cutter with their own hands

Chisel. a useful tool, with which you can correctly and evenly cut the corner at the baseboards on a slanting scaffolding. Despite the fact that the chisel seems to be a simple device, to make it with your own hands, you need to understand what this design is for and how to use it.

- Chisel made of plastic will not last long, it quickly wears out and the cuts become imprecise;

- If you plan to install large, wide skirting boards, the filling strip should also be wide;

- You need to fasten the sidewalls securely to keep them from falling apart.

Before cutting the skirting board, it is worth either buying a ready-made chisel, or making one yourself. For this, you can use a simple sheet of paper, or bars of wood.

If a saw is available, you can make a jig from a solid piece of wood by sawing out the middle and side cuts on the bar

To make a crosscut, you will need: a board for the base, 4 boards for the walls and sides, a hacksaw, a drill, drill bits, nail file and screws. First assemble something like a box from boards, and then saw holes in it. The length of the sides is 6-8 cm. A hacksaw or circular saw is used to make them.

The cuts are made at right angles. They must be cut carefully. The mowing line should run in the same direction.

Special features of the cutting of different materials

Ceiling decorative tacks are strips of varying density, width and hardness, depending on the materials used for their manufacture.

For installation work, it is important to correctly cut the skirting board for ceiling decoration so that its corners form beautiful joints in straight areas or in the corners of the room to be decorated.

Baguette for the ceiling, made of different materials, has certain features when installing and cutting.

- The foam moldings are the most unstable type of material to any, even minor mechanical damage. But the foam products have a light weight and low price. Such ceiling molding can be painted with acrylic dyes in any shade you want. The foam is easy to cut, but at the same time it also crumbles. It can be cut with a hot wire clamped in the jaws, a joiner’s cutter, a hacksaw, or a simple, but sharp knife.

- Styrofoam molding. Such a product is similar to the foam analog, but the strength of polystyrene material is an order of magnitude higher. Products made of this composition are lightweight and cheap. Styrofoam can be machined with a sharp knife or a metal saw.

- PVC skirting board. This material crumples easily, after which it is impossible to restore its original appearance. For this reason, use great care when fitting PVC skirting boards, and apply pressure without excessive force. Polyvinylchloride mouldings can be cut with a carpentry cutter, a sharp knife or a metal hacksaw.

- Polyurethane skirting board is the most durable material, which, unlike plaster moldings, weighs much less, but is not organic. This type of decoration is simple to install and does not require particularly complex fitting procedures. For trimming corners you will need a small fine-toothed saw or an ordinary hacksaw, as well as a plane.

- Aluminum molding. the most stylish type of material used for modern design, it is lightweight, durable and has a high aesthetic. For trimming it requires an electric saw or a hacksaw for metal, as well as a plane saw. To process an aluminum molding a craftsman should be very precise, since cutting errors and inaccuracies will be very difficult, and more often than not impossible to correct.

- Wooden cornice is another sought-after and durable material that can be used for ceiling decor. Its advantages are considered to be strength, hardness and the ability to withstand loads of a certain complexity. Wood ceiling cornices are easy to handle, which is carried out with an end saw, a wood hacksaw, as well as a metal blade. The wooden products retain their original appearance for a longer period of time than their foam counterparts. If desired, the cornice can be painted or varnished.

If we compare the foam and polystyrene foam, both of these materials have a special softness that makes it possible to press the skirting to the work surface, without leaving any gaps during installation. Most ceiling mouldings have recesses designed for mounting the ceiling illumination system. With regard to wood and aluminum, then to join the corners or cuts in these materials is quite difficult. The same applies to plastic materials. To cut such a molding will need to use a wire cutter, and the process of work should be carried out carefully and very accurately.

Installing the baseboard

Trimming of a skirting board is finished, finally, the moment of installation has come. This process is no less important than just trimming the skirting boards. It is worth using glue or sealant to glue the skirting boards to the ceiling.

For baseboards, which are made of polyester and similar materials, special glue is quite suitable. For wood and semi-synthetic materials, it is better to use sealant.

After that moment, when the strips will be put in place, begins their final adjustment. It is worth remembering that before you glue the skirting boards, they should first be tried on the junction of the ceiling with the walls.

The last, but not the least important stage, is cosmetic work. With the help of a special putty is sealing the cracks, small damages and irregularities. Thanks to the putty, you can align and finalize the corner.

It is better to use acrylic putty rather than plaster putty. Acrylic putty, unlike plaster putty easily withstands moisture. If you use gypsum, then at some point in the bathroom, you may notice that its pieces will begin to crumble directly on the floor. To apply putty, you must first sand everything down, but such manipulation can damage the baseboard.

Another notable difference is that the gypsum putty must be diluted yourself, acrylic can be bought ready-made. Someone may say that dilute it will not be a problem, but this is not entirely true, because in order for the result of puttying to be qualitative, putty must be made in the correct proportions. Otherwise it will start to crumble. Acrylic putty is a little more expensive, but has a number of advantages, so the price is justified. The disadvantage of acrylic putty is that in the situation. When the layer should be more than 10 mm, it will not work, but in the situation with the skirting boards should not be such a problem.

Once the question of which putty is better to use, decided, you can begin to work. Putty should be applied over the entire baseboard and adjacent walls, a thin even layer. After the drying of the first layer usually requires a second layer to consolidate the result. Apply carefully in order not to stain the walls and ceiling.

How to cut a corner with a mortar

Pliers. joiner’s tool, with which you can cut any material at an angle of 45 and 90 degrees. The frame can be made of wood, plastic or iron. Even the simplest fixture has openings for a hacksaw, the more expensive models even have a swivel mechanism.

The principle of working with a jigsaw is very simple. Place the skirting board in the groove, press it and cut through the side holes. As a result get a cut at the right angle.

- Measure.

- Put the skirting board face up into the groove of the mortise.

- Press down on the slat with your hand, but not too hard (if the skirting board is made of Styrofoam, it can easily be broken).

- Insert a hacksaw at a 45 degree angle into the opening of the wood chisel and make the cut

- In a mirror image in a similar way to cut the second piece. The formed inner corner is obtained.

Tip! It is possible to cut a skirting board with a metal hacksaw, but if the baguette is narrow, it is better to use a construction knife, it makes the cut more even.

Cut the outer corner just as easily. Step-by-step instructions:

- On the underside of the skirting board, we mark the desired length, but its edges must be slightly outward.

- We put the slat in the jig at an angle of 45 degrees and make the cut through the holes.

- Mirror-cut the second plank.

- Prepared elements we attach to the wall. If everything is even, then glue, and if there are flaws, then simply remove them with a sharp knife.

If you have to work with a wire cutter for the first time, it is better to pre-practice on extra pieces.

Materials and features of their cutting

The answer to the question of how to cut a ceiling plinth, depends on what material it is made of. Cutting is different, since baguettes have different density. Therefore, the first thing to consider is the most popular materials, and at the same time the peculiarities of their cutting.

Styrofoam

Such products have the lowest price, because the material is very unstable to mechanical influences. Styrofoam is easy to scratch, damage if accidentally hit. Advantages. minimum weight, which simplifies gluing, easy processing, the ability to paint in any color.

This foam material consists of small granules, which are quite easy to separate from each other. However, they are the main disadvantage of such baguettes. They require a very sharp tool. Otherwise, the skirting board can crumble, so it will be unsuitable for installation. This is true for both angular and flat cutting.

Styrofoam

This contender is more expensive, but it is not very different from the first candidate, because it is a “relative” of Styrofoam: it is produced from expanded polystyrene. This material also consists of small granule bubbles, but they adhere to each other more densely. But polystyrene foam will not tolerate a blade that is not too sharp, it will also crumble. Therefore, the craftsman needs to prepare an equally sharp instrument.

The main advantage of Styrofoam and polystyrene foam is their softness, which allows you to avoid gaps by pressing the pieces tightly to each other and to the corners.

Extruded polystyrene foam

EPPS is made from the same raw materials as conventional polystyrene foam, but in this case uses a different, more advanced technology. Conventional EPS is made with steam, which is passed through the microgranules.

To obtain the extruded polystyrene foam, the particles are mixed at high temperature and the same pressure, and then foaming agent is added to the raw material. The grain size in this material is much smaller (maximum 0,2 mm), as a result it is less crumbly and more resistant. Very sharp tools are not required to cut it, but bluntness of the cutting edge is also not welcomed.

Polyvinyl chloride

Plastic skirting boards (PVC). another type of ceiling products. They are usually purchased for finishing bathrooms. If we consider the topic “How to cut a ceiling plinth“, in this case they are exceptions, because for their docking use special, ready-made corners.

In general, these baguettes can be cut with a box cutter, a metal hacksaw or a sharp kitchen tool. Since PVC products do not restore the shape due to the lack of elasticity, it is not recommended to put a lot of pressure when cutting.

Polyurethane

This is another representative of polymer products. It has a high density and lacks the disadvantages of previous competitors. It is easy to cut, so the tool must be sharp, but its sharpening is not subject to the maximum requirements. Polyurethane skirting boards do not crumble, do not deform, and can handle almost any pressure with honor.

Wood

This traditional material is cut with the usual carpentry tools: for example, a jigsaw, hand or electric. Places of the cut are processed by abrasive paper or file. Since these products are more expensive than other skirting boards, when working requires care. It’s easy to make a big mistake and there’s nothing you can do to correct it. The consequence of negligence will be the purchase of a new baguette.

The ideal tool for cutting wood will be an electric mitre saw. Its biggest disadvantage is the high price, especially for quality models. On the other hand, buyers have the opportunity to find an inexpensive tool that will do the job decently.

To properly and accurately cut the ceiling plinth, you need to use the right tool for cutting. It is chosen depending on the material from which the fillet is made:

-

Styrofoam. Characterized by low strength and costs relatively inexpensive, and therefore foam models are becoming increasingly popular. Their strength does not particularly affect performance, because usually the ceiling plinth is not subjected to mechanical stress. An ordinary box cutter is suitable for cutting.

It can be purchased in a construction store or make your own hands according to these instructions:

-

We nail three 5015 cm boards with a long edge into a shape of a three-sided rectangular box. Note the 90 degree angle between the side planks and the cross plank.

The first method. with a jig saw

Professional planer with a rotary hacksaw

Chisel usually looks in the form of a tray with vertical holes for a hacksaw. It can be made of wood, metal or plastic. This tool represents the oldest and simplest carpenter’s tool, designed for cutting wooden parts at an angle of 90° and 45°. There are types of such a device and for professional work, with a swiveling mechanism, in which the cutting tool can be rotated and fixed in any position.

How to cut a skirting board properly

Ceiling corners are divided into internal and external, the method of joining them slightly different.

If necessary, you can make a chisel with your own hands. You will need three strips of plywood or boards of equal size. First they are laid in the shape of an inverted U-shape and the corners are marked. Then, according to the markings, cuts are made for the hacksaw almost to the bottom, and the boards are twisted.

Inner corner

- Making correct measurements.

- Position the baseboard plank in the mortise so that this position is exactly the same as the placement on the ceiling.

- The baseboard must be pressed firmly against the opposite wall of the joiner. Hold it and press it down with your free hand.

- We put the hacksaw at an angle of 45° in a special hole and cut the piece.

When cutting soft materials (PVC, polystyrene foam) use a metal saw or a regular construction knife. Then the work will be neat and with straight edges.

Outer corner

- Measure the length of the baseboard from the nearest wall to the outside corner, leave a line of pencil on the wrong side, marking the desired length. Note that the edge (its upper part) must protrude slightly outward.

- The skirting board is moved to the joiner and cut off.

- The adjacent plank, too, should be measured with a margin and cut in mirror image to the first part.

Trying on the ceiling plinth: the joining of parts must be perfectly flat. If the result is not achieved, and the joints are uneven, you can trim the edges with a regular knife until the perfect join.

Step by step instruction

When installing a ceiling plinth first you need to prepare the surface before pasting skirting, it must be cleaned of small irregularities, then you must primed the adhesive places to create maximum adhesion between the adhesive and the wall or ceiling. The primer is suitable the same that was used for gluing wallpaper or ceiling tiles.

Before gluing it is recommended to take a small piece of baguette and practice cutting corner joints, so as not to spoil the excess.

So, you’re all prepared, and it’s time to start the process of cutting corners. To create an inner corner you are well suited to the first of the above methods. If you have a flat wall, you can cut off the baguettes equal pieces, and cut corner joints from them, then just glued them accurately at the stop long strips. These manipulations will facilitate your work when trimming and eliminate the possibility of baguette bending or breaking.

If the walls have flaws, and you’re worried that the place of gluing will then be visible, you can fit the corner on the floor, and then glue.

When cutting the outer corner, remember that the inner corner rests against the wall, and the outer one, on the contrary, protrudes over it. Similar to the method described in the first method, you can try. The only difference will be that the output of the skirting board outside the wall is needed to the width of your baguette trim. After trimming strips at the correct angle and joining them, you may need to adjust the angle manually, since the corners of our homes are often not even close to 90 degrees. The rest of the methods we’ve described will allow you to make an outside corner more easily. Just like when cutting an inside corner, it’s better to practice first. this will make your job easier, and reduce the skirting waste.

Before gluing the skirting boards, make sure that the joints fit exactly. Modern mounting adhesives quickly take hold, so the time to fix a mistake you almost will not have, and tearing baseboard. and the possibility of breaking it, and the need to re-scratch the surface of the skirting and the wall of the glue. Excess glue is better to remove immediately with a small clean rag or sponge, so that no traces are left.

With proper patience and proper fitting you can achieve “seamless” connection, and your baguette will look solid, which will simplify your further painting and eliminate the need to use finishing putty to smooth out the connecting seams.

Cutting peculiarities

Let’s consider in more detail how to properly cut the corner on the ceiling plinth with the use of a jigsaw, using different materials.

Polyurethane

Polyurethane foam (colloquially just polyurethane) is a very good material for ceiling skirting. Because of the good flexibility, it accurately adhere to the base (the joint between the wall and ceiling), even if due to construction errors walls and ceiling are uneven. In addition, polyurethane is well-washed, and therefore can serve for a long time. Low load resistance is not a problem here: there is almost no load on the ceiling plinth. We also have a separate article, which deals in more detail on how to make your own ceiling from plasterboard and false ceilings from plasterboard.

Cut the polyurethane skirting board with a wire cutter as follows:

- Measure the wall and ceiling at the junction.

- Choose a suitable template on the jigsaw for cutting.

Styrofoam

Styrofoam is also often found as an element of room decoration. Its characteristic feature. the increased fragility, so it must be fitted on the spot it is extremely accurate, no deformations foam does not tolerate.

It should be cut with a jigsaw as follows:

- The baseboard plates are laid in a jig.

- The cut is made. Unlike polyurethane foam is a soft material and can be cut even with a knife or better. a clerical or construction cutter. Here it is better to use a small, but straight piece of wood, a metal plate or a ruler. In a pinch, you can make pencil marks corresponding to the slots in the jigsaw, connect them with a ruler. and make the cut.

Asterisk IMPORTANT: Styrofoam is a fragile material, so the cutting tool should be sharpened as best as possible.

Polystyrene

Polystyrene has the same properties as foam plastic. That’s why polystyrene skirting boards are cut in the same way as Styrofoam. The main thing here is to sharpen the cutting edge of the tool as sharply as possible to avoid chipping. There is no need to machine the cut ends with emery cloth, as the edges are often fluted enough as it is to ensure good adhesion of the adhesive.

Wood

Wooden skirting boards are rare and expensive, so they must be treated responsibly. The technology of cutting looks like this:

- The cut ends are clamped in the joiner.

- The cut is made. It can be done with an ordinary wood hacksaw, but it is better to use a special saw or metal saw to avoid too wide a cut.

Asterisk IMPORTANT: you have to be extremely careful when trimming; it is better to cover an uneven cut with a decorative overlay or a wood filler than to chip away at a too large piece of wood.

Plastic skirting boards (PVC) are now widely used. It is convenient because:

- Easy to cut with any tool.

- Flexible, can be used even in uneven corners.

- Usually has an internal cavity, so it can be used as a conduit for electrical wiring or fiber-optic lines for the Internet.

PVC skirting board is cut in the same way as polyurethane. However, you should consider: the best tool, a metal hacksaw with fine teeth, is suitable only for thick baseboards, in the thin it can tear out pieces. So the best option for thin items is a stationery or construction cutter or a sharply honed knife. It needs a certain skill to use it, so it is better to train beforehand on scraps or sheets of thin plastic.