How to saw Laminated chipboard with a jigsaw without chipping

How to saw furniture board without chipping. Cutting Laminated Chipboard at Home. Choice of saw blades and blades

You will also need additional tools for sawing:

Cut Laminated chipboard in the following order:

- Material marking. A ruler and pencil are needed to mark the workpieces, in order to draw dots on the sheet of material from the end. Then the dots need to be evenly spliced into one trimmer line and glued on top with painter’s tape. A good way to cut Laminated chipboard without splitting is with masking tape. к. It helps reduce the number of sheet cracks that can occur due to excessive heat and pressure. Sawing Laminated chipboard.

- The next step is sawing Laminated chipboard. How to saw Particleboard, and place the tool at the desired angle to keep the edges of the saw blades straight. Cut Laminated chipboard and hardboard as gently and as smoothly as possible.

- Plate processing. If the sawn chipboard at home is uneven on the cut faces, they are machined with a belt sander. In some cases it is better to immediately contact a company that provides services for the production of furniture parts to order according to customer dimensions and sawing Laminated chipboard on special equipment. To glue the edging on parts, a special gluing edge is used for processing.

Accuracy and quality

Formal cutting machines for cutting laminated chipboard and particle board have high cutting quality which allows to reduce post-cutting processing costs (sanding, deburring, removal of chips and so on). That’s why such machines can be used for cutting any complexity and configuration, which means almost limitless possibilities in furniture production. Fancy children’s furniture, comfortable computer desk tops, shaped carvings in the doors of kitchen fronts. all this is possible with the use of machine tools.

Panel cutting machines come in two varieties:

- Vertical, rigid vibration-resistant welded frame, set vertically with a 50° tilt to the back, with guides at the top and bottom, on which the saw beam moves. It is the bracket for the saw unit, which moves up and down along the beam and rotates through 90°, allowing both vertical and horizontal cuts. Cutting precision is amazing. The special scoring unit is used to cut laminated chipboard as well as hard, corrugated or porous boards. The saw blade rotates at up to 15,000 rpm;

- horizontal, consisting of a table for the board, a carriage to move the saw along the sawing mechanism and the sawing mechanism itself, consisting of one or two cutting units. Cutting units are equipped with a main saw and a scoring saw. The principle of operation is simple: the main saw cuts deep into the chipboard, while the scoring saw finishes the bottom edge (veneer or laminated surface) precisely and accurately. The saw unit can also be tilted by up to 45°.

The mitre saw is a home-made and highly reduced version of a horizontal machine. Saw a wide sheet of chipboard or laminated chipboard on it can not, but with small parts it is quite able to cope.

How to saw particleboard without chipping

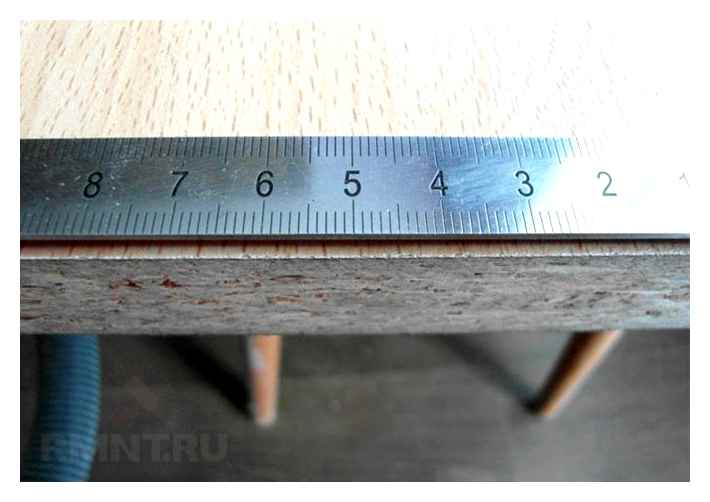

In order to saw evenly and splinter-free chipboard at home, you need to know a few tricks. Without any doubt, it is better if you will saw with an electric jigsaw. Of course, you can also saw with a hacksaw, but the result is unlikely to please you, although it is possible to saw chipboard for various purposes, where the quality of the cut does not play any role. And so, we need a smooth and beautiful cut. To do this we take a jigsaw, a ruler, a tape measure and an angle bar for right angles (if it is necessary), an awl or a sharp object with which to trace a fishing line for a trimmer on the laminate chipboard. We measure a part that we will saw off with 1-2 mm reserve on the subsequent adjustment and we put a ruler, on it we guide with an awl or a sharp object a line for a saw trimmer, try to press harder to cut through a laminate, and we saw along the line not on the line itself, but exactly along, only catching it with an edge of a saw.

Then with coarse sandpaper finish the edges of our saw cut to the right state, and if the quality of the sawn end is not satisfactory to you, we take a wax chalk in the desired color t.е. in the color of particle board and grind up the chips. Let’s talk about jigsaws, I personally use BOSSNevski.

If you need to saw without chipping on one side only, you can use saws with both up and down tooth, I use small saws with a straight tooth they chip off less and the cut on both sides is pretty good. It will be more convenient to treat the sawn end with sandpaper if you stretch it on a flat bar. Furniture wax crayons and markers you can buy in furniture stores, where they sell fittings. If you can’t find a crayon in the color you want. No problem-it can be made from several others by mixing like paints. Simply melt crayons with a candle and drop on a plate, one color on it another, then roll into one and rub the edges with chips, remove the excess with a ruler or knife and polish with a rag gently, no need to press hard.

What tools can be used

A hacksaw

This tool is used for the good old-fashioned scratch-cutting method. I must say that a good quality cut with a hacksaw is difficult to achieve.

- First, we scratch or cut the line for the trimmer metering on the material with some stabbing-cutting tool (for example, a knife) and glue the tape over it. It is needed in order not to damage the laminate surface.

- We guide the hacksaw to the material at an angle of 30 degrees and move it smoothly back and forth. Chips from it will definitely remain in this case.

- If damage from the hacksaw remains, go over it with a file (from the edge to the center).

- The final step is to process the cuts Laminated chipboard with sandpaper, so that there are no rough edges.

The main advantage of a hacksaw is its affordability and ease of handling, but it does not perform the function we need to prevent chipping, so we do not recommend its use.

Jigsaw

Electric jigsaw. this is the most popular solution at home, as the tool itself does not cost a fabulous amount of money, and therefore available to the average consumer.

Jigsaws for sawing worktops with the jigsaw must be short (no more than 75 cm) and have Class A or B teeth suitable for Laminate chipboard.

In the process of sawing with the jigsaw, you need to make smooth movements with the tool without pressure at a speed slightly above average. With the greatest likelihood of chipping it is on the opposite side of the board from the one in which the jigsaw teeth enter.

Chips appear on the reverse side of the board in the process and spoil the appearance of the workpiece. They can only be removed by the cutter, which is an additional amount of work and overconsumption of material. So this tool is not suitable for us either.

Circular saw

Circular (or circular) saw. another tool that can be used for making furniture parts.

To cut the workpiece, it is necessary to mark out guide lines on the boards and clamp the saw to the board, but it is not guaranteed that the edges of the pieces will be straight. Chips appear on the reverse side of the board. And the only way to chip them is with plastic profiles with snaps on the ends Chipboard. But the circular saw. not the cheapest pleasure, and even with it you can not avoid chips, so in this case, there is no sense to overpay.

Milling cutter

Another option for sawing laminated Chipboard is a power tool for manual woodworking. It is used in combination with the jigsaw. The process looks like this: first saw Laminated chipboard with a jigsaw, moving slightly away from the marking, and then a cutter with a bearing, which deepens the cut to the desired level.

The main disadvantages of this tool is that it is not as common as, for example, an angle grinder, and will not find everyone in the house. Well, its use. it is quite a labor-intensive process, which can handle only qualified specialists, and the beginners should not even approach it.

Circular saw

The most correct cut and a guarantee of absence of chips can provide only one tool. panel sawing machine, which refers to the professional equipment. Since the machine is very expensive and is used mainly in production, amateurs usually can not afford it. The only optimal solution in this case is to turn to professionals. Companies that specialize in the sawing of parts for furniture, usually use these machines in their work.

The format-cutting machine has the following settings, which are set depending on the length and width of the panel to be sawn:

The machines themselves are divided into the following varieties:

The components of the format slicer, which allow you to ensure accuracy and absence of chips in the manufacture of parts:

- bed. it is a stationary base of the machine, which all other mechanisms are mounted on. The heavier it is, the better for sawing, because this eliminates vibrations and oscillations that can interfere with the process;

- The scoring unit is the element that pre-saws the workpiece blank and serves to ensure that there are no chips at the bottom;

- The main saw serves for the final sawing of the plate and is responsible for a clean cut without chips on top;

- Work tables. there are three of them. The first is stationary and serves as the base for the undercutting assembly, the second is movable and it feeds the plate to the disk, the third serves to support the parts that are sawn off the plate;

- carriage. is a part of the machine that makes it possible to move the format table;

- stops and rulers. components whose main function is to fix the plate in the right position.

The design of format-cutting machines allows them to provide such accuracy in sawing Laminated wood chipboard for furniture parts, which no other tool can guarantee. It’s also the only way to completely avoid chipping.

Rules to follow when sawing

Now that we have the tools, let’s move on to the accessories you need.

The correct procedure for sawing Laminated chipboard looks like this:

- First we mark out the material. To do this, take a pencil and mark the cutting points on the end face of the laminated chipboard. After drawing all the points, we connect them into one line for the trimmer and glue the adhesive tape on top of it. It is best to saw Particleboard with a laminated surface using adhesive tape, so that it reduces the number of cracks when splitting. They appear because laminated chipboard is subjected to high pressure when the temperature rises.

- Then we saw a board. To do this, set the selected tool at the right angle to ensure that the part has even edges. The process itself should proceed smoothly and gently, without sudden movements.

- Treat the board. If irregularities remain on the edges of the board later on, these can be filed. And the cut lines are processed with sandpaper.

Most often amateurs overestimate their strength and take it upon themselves to saw details from Laminated chipboard, and then regret that they did not turn to professionals immediately. After all, a specialized company guarantees you finished parts for furniture without chips, made to your drawing with millimeter accuracy. In addition, finished parts need to glue the edge, which you will not do at home, because this requires a professional gluing line for the trimmer, with which experts and process workpieces.

Recommendations for a splinter-free cut

First, as already mentioned above, you should use a jigsaw file with a straight cut.

Secondly, in order to better control the process of cutting, it is justified to apply the marking line for the trimmer on both sides Laminated chipboard and check the accuracy of processing the top and bottom.

And thirdly, to take constant breaks in the work to cool the cutting equipment.

Sometimes the solution in this matter can be a simple cutting through the laminated layer of material with a mounting knife, and the subsequent work with a jigsaw will no longer cause major defects in the form of chips. However, this work requires a certain experience and accuracy from the performer.

If you liked the material I would be grateful if you recommend it to friends or leave a helpful comment.

Reception 2. “Reverse cutting”.

The first pass is performed in an unusual manner. backwards. That is, the circular saw rotates in the course of the feed of the workpiece. We set the minimum depth of cut, switch on the saw and move it backwards instead of forwards.

If you have a regular saw, you just fix the saw with a minimum of protrusion over the base. The point of the first pass is to make sure that the blade just clings to our board when it’s moving along the guide. We need a small groove on the chipboard.

Having made the first undercut you will see that there are no splinters at this feed (back). The surface is perfect!

Now we set the saw to full depth and saw the workpiece along this groove with a normal forward feed. So we have two cuts per workpiece. No waves, no burns, nothing. perfect quality!

Cutting a chipboard

If we have the right tool and position the marking correctly we won’t have any problem cutting chipboard. The most important thing is to move very slowly. Even when using a fine-toothed saw, chipping can occur during sharp actions. Cut through the chipboard, without attempting to partially cut through it. Cracking the material without leaving any cracks is impossible afterwards.

How to saw evenly Particleboard or Laminated Particleboard with a jigsaw

To saw cleanly Laminated chipboard with a jigsaw, it is necessary to follow a clear algorithm. It looks like this:

- The workpiece is firmly fixed on the work table. Do not wiggle or flutter when cutting, otherwise you won’t get a straight cut.

- The surface of the material is marked. If the lines must be drawn on the front side, it is better to use a pencil rather than a marker, traces of which can then be erased.

- The electric jigsaw is inserted into the selected nozzle, preference is given to brand new and high quality blades from well-known brands. If you plan to saw the workpiece cleanly, old and cheap jigsaws should be avoided.

- Set the maximum stroke frequency in the tool. You do not need to change the angle of the jigsaw. The pendulum mechanism should be switched off. It makes a fast cut easier, but often does not cut Laminated chipboard accurately and evenly.

- Place the jigsaw firmly on the marked line and press it firmly against the material, then start to work.

- Slowly and accurately guide the blade along a pencil or marker line, using backlighting and a laser pointer if possible.

If laminated chipboard needs to be sawn without chipping and defects, it is better to place the material face down even when using the reversing head.

When cutting chipboard with an electric jigsaw it is recommended to use a special splinterguard. It is a small piece with a kerf, which is installed in special guides on the bottom of the tool. Ideal results are achieved by using an insert with a hole exactly matching the thickness of the blade. The part can be delivered with the tool in several pieces, the opening in it is usually proposed to make it yourself.

Attention! To get a clean cut with the chipboard jigsaw blade, it is important not to overheat the saw head.

It is essential to remove sawdust from the cutting line in good time, otherwise you won’t be able to saw laminated chipboard evenly

The use of adhesive tapes

Duct tape (i.e. masking tape) is for protecting the back side of the material. It is necessary to stick a tape on the line for the trimmer of the cut, which keeps the processed cloth from tearing off large elements. Painting tape is not a very effective option for saving material when cutting with a jigsaw, because its strength is very low.

It is best to use a wide enough (each side of the cut material should be covered by at least fifteen centimeters) aluminum or fiberglass reinforced tape. In addition, the tape should be pressed down with a dry cloth to eliminate the risk of wrinkling.

Using the adhesive tapes

Adhesive tape (such as ordinary tape) is to protect the back side of the material. It is necessary to glue a tape to the trimmer’s fishing line to keep the processed fabric from tearing off large elements. Painting tape can not be called a very effective option for saving the material when cutting with an electric jigsaw, because its strength index is extremely low.

It is best to use a fairly wide (each side of the cut material should be covered by at least fifteen centimeters) aluminum or reinforced fiberglass tape. In addition, the adhesive tape should be pressed down with a dry cloth to eliminate the risk of creasing.

Repairing any splintering that has occurred

Cutting the material with a jigsaw and avoiding chips is almost impossible. You can do this: cut the part with the jigsaw with a small allowance (2 mm), and then mill or grind the allowance with the belt grinder. Milling produces a cleaner edge than with a grinder. The material is usually milled on a self-made (based on the design of a circular saw guide) guide rail. Spiral cutters will improve the quality of milling. Two of these must be prepared.

If you want to keep only the face side clean, you have to use an ordinary two-pass cutter. If you want both sides clean, a four-feed cutter with two left main and two right side undercutting branches is recommended. That way when you cut material the upper branches push it down and the lower branches pull it up. This prevents chipping of the edges.

Circular cut

Curvilinear surfaces of a given configuration to get at home is even more difficult, it will have to spend extra money on a router, which will help you get rid of chips and nicks formed when you cut chipboard.

Price of a hand router can vary significantly, depending on the manufacturer, capacity, availability of additional functions. If you are not planning to engage in the production of furniture professionally, it is advisable to buy an inexpensive model.

To cut the chipboard you need to do the following steps:

- After marking the outline of the required part on the sheet of chipboard, cut it out with an electric jigsaw, trying to saw away just a couple of millimeters from the planned cutting line;

- Make templates of the design radius from fiberboard or plywood, and carefully sand the ends with emery cloth;

- Applying the template to the part to be decorated, clamp it with clamps, and process with a manual coping cutter with a bearing, removing excess material exactly to the planned line.

In this case, it does not matter what cutter (with two or four knives applied). The only condition is that the knives must capture the full height of the thickness of the cut to be processed. After the work is finished, the only thing left is to glue the edge on the part. See how to do this at

What you can’t use for sawing Particleboard

If the amount of work is large enough, and the quality requirements are low, some masters advise to saw chipboard at home with a grinder (angle grinder, commonly called “angle grinder”). In doing so, they use a disk designed for working with wood. To make it easier to cut, a guide rail is clamped along the cutting line with the help of clamps. Sawing chipboard with the use of an angle grinder can sometimes be seen in the video.

Attention, it is important! This method is absolutely unacceptable, since there is a very high probability of injury at work, especially if large-diameter discs are used and the protective cover is removed from the grinder.