How to sharpen a band saw correctly

Wiring methods

The ways One of the easiest ways to set saw teeth is with pliers. You just need to take each clove and bend it alternately in different directions.

The tooth must be clamped by two-thirds, then the slope will be correct.

As a result of this work, half of the teeth will be bent to the right and half to the left. Another wiring method is carried out using a special tool.

Saw care

Care It is important to be able to not only raise and sharpen a saw. You also need to know how to store it. When not in use, the tool should be placed in a warm and dry place. If moisture gets on the saw, it will rust.

Even treated with special compounds, the saw will not be able to withstand all aggressive factors.

You need to take good care of the instrument, and then it will serve for a very long time. The saw is stored usually wrapped in material. You can also provide a case for it. Leaving the tool on the balcony for the winter is not recommended.

How to sharpen and spread a saw

- 1 Why bred a saw

- 2 Wiring methods

- 3 Sharpening

- 4 Caring for the saw

- 5 Types of band saws

Band saw blades are often sold unsharpened. A professional tool must first be diluted and then sharpened. The wiring process is repeated every two to three years. An improperly set and poorly sharpened saw can ruin the whole job.

How to sharpen and spread the saw correctly? First you need to understand the essence of these processes. After all, the preparation of a hand tool is different from the preparation of an electric one. Hand saws have a completely different tooth shape and working technique.

Sharpening

After breeding, the saw must be sharpened. This is done using a special set of simple tools. You can simply sharpen the band saw using a conventional triangular file. During sharpening, moving the file away from you, it is pressed against the teeth. Moving in the opposite direction, it must be slightly deflected.

If you can sharpen a circular saw only with a whole set of tools, the band can be brought into working condition with just one simple triangular file.

The band saw teeth should be sharpened from two points.

How To Sharpen A Band Saw Blade And Set The Guides!

In the working process, you can also sharpen the teeth with a bar. When the saw is constantly sharpened, the wiring gradually disappears, the teeth are aligned. In order to return the instrument to its working shape, dilution is repeated again. Capital wiring and sharpening is not required very often.

Why bred a saw

Saw set

Setting is a process that causes the teeth of the band saw to bend back and forth. Even teeth are bent to one side, odd teeth to the other.

Before diluting the band saw, you need to understand why it is needed. Pointless processes usually do not bring good results. It is known that during sawing, the cutting width must be twice the thickness of the saw blade. If the cut is narrower, the saw will get stuck in it. If the wiring is incorrect, the curvature of the canvas is possible. As a result, the saw will go crooked, and an even cut will not work.

Types of band saws

Two-handed saw

Band saws vary in tooth size. You should also highlight:

- two-handed saws;

- single saws.

Two-handed saws are sharpened and set in the same way as regular single-handed saws. The whole difference between such a tool is that two people work with it at once.

With the help of band saws, wood and varieties of this material are most often sawed. Wood does not require too much impact, it is a soft material that is easy to saw and drill. However, in the process of work, it is still advisable to fix the logs and boards. When cutting, be careful not to keep your hand too close to the cutting furrow. This can lead to serious injury.

What you need to know about sharpening angles

The geometry of the teeth of band saws can be modified depending on the characteristics of the material being processed. This is expressed in the shape of the tooth and the distance between the individual elements of the cutting edge.

The saw band profile is determined by the markings applied by the manufacturer. It looks like this:

- WM. a universal version designed for sawing soft and hard wood;

- AV. used for longitudinal cutting and sawing of hard materials, such as frozen wood;

- NV. has a narrow blade width, so it is ideal for shape cutting;

- NU. a cutting edge with a wide tooth pitch, which provides high performance when cutting soft wood;

- PV. almost a complete analogue of the previous blade, but has a flattened tooth shape;

- KV. the profile is used for wide band saws intended for softwood;

- PU. wide saw blade for cutting hardwood.

The pitch of the teeth is selected individually, depending on the material. For example, when cutting hardwood and metal, only fine-toothed blades are used to avoid damaging the cutting edge. Soft raw materials and thick-walled materials are processed with saws with a large tooth spacing, which allows to speed up the production process.

Sharpening

This is the main step in cutting edge dressing and can be done in two ways.

Full-profile saws are sharpened with an CBN wheel installed in a special sharpening machine.

This is a fully automated operation used by professionals. The work of the machine for sharpening band saws for wood is controlled by electronics, and the sharpening wheel processes the entire band in one pass. The disadvantage of this method is that the CBN wheel is selected individually to the profile of the saw, therefore, for dressing different tools, the sharpening element must be present in the assortment.

Sharpening of teeth is carried out manually or on specialized equipment.

Note! This is the method used for self-sharpening band saws. A normal emery wheel or file can be used here.

In the first case, the sharpness of the teeth can be restored in the shortest possible time, but the work requires certain skills. In the second. painstaking work: 4-5 movements along the edge of each tooth.

For automatic sharpening, diamond, CBN and corundum wheels are used. It is important to understand that when performing this procedure, only sharpness is given to the teeth, the geometry created after setting the blade should remain unchanged.

How to sharpen a band saw correctly

Immediately, we note that if there is no experience and skills in performing such work, it is better to entrust saw sharpening to professionals. Violation of the geometry of the teeth of the cutting edge, the appearance of dross on the metal or incorrect setting will significantly reduce the life of the blade.

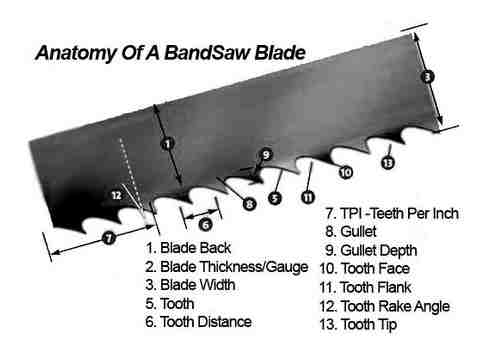

Having decided to sharpen the band saw with your own hands, it will be useful to first familiarize yourself with the key definitions, the knowledge of which may be required in the process. So, for the correct formation of the cutting edge you will need:

- setting. deviation of the teeth from the plane of the main saw blade;

- the height of the teeth is the distance between the top point and the base;

- pitch. the distance between the teeth, usually varies between 19-25 mm.

- sharpening angle. depends on the intended purpose of the tool; for example, the recommended sharpening angle of carpentry saws is 35 °, indexing. 18-22, intended for sawing a bar. no more than 15 °.

The sharpening angle is determined by the manufacturer, therefore, when self-dressing the saw, it is recommended to adhere to these parameters.

Here are detailed instructions that will help you sharpen a closed saw correctly without resorting to the services of specialists.

The subtleties of the setting of band saws

As the tool is used, the quality of its cutting edge decreases. Therefore, setting and sharpening the band saws correctly is a natural part of the workflow.

Note! Divorce should be done before sharpening, not after!

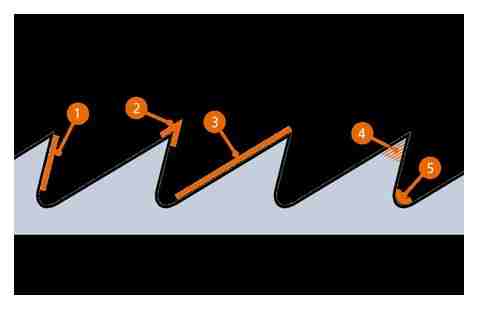

Setting is the operation of bending the teeth to the sides to prevent jamming of the tool blade and reduce its friction. There are three main types of wiring:

classic. the teeth are bent to the right and left of the side strictly alternately;

stripping. every third tooth is left in its original position. “Relevant” for tools used for cutting especially hard materials and alloys;

wavy. each tooth has its “own” value of the bend size, thus, a wave is formed from them. This is the most difficult type of wiring.

Worth knowing! When divorcing, not the entire tooth is bent, but only part of it. a third or two-thirds from the top.

The values of the divorce rate recommended by manufacturers fall within the range of 0.3-0.7 mm. The operation is carried out using special adjustable tools.

Wiring

Setting band saws into wood is the first step in restoring the profile of the cutting edge. During operation, the location of the teeth can change, so until the correct geometry is achieved, it makes no sense to sharpen the saw part.

There are 3 ways to open the saw:

- classic. the teeth alternately deviate to the right and left sides;

- stripper. the 1st and 2nd teeth deviate in different directions, the third remains even. This profile is created for sawing hard materials;

- wavy. the most difficult option, resembling a wave in shape. Here, each tooth is individually shaped, and this type of setting is usually performed only in specialized workshops.

It should be noted that when wiring, not the whole tooth is bent around, but about 2/3 of the upper part. The procedure is performed on a special band saw setter. The cost of such a tool is quite high, so they buy it if you need to adjust several tools. Its presence can become the basis of a sharpening business.

Of course, the first time you can do everything correctly, even on an adjustable machine, it may not work, so at least the geometry of the profile should remain the same as before the start of work.

How to sharpen band saws correctly

Band saws are cutting tools used in band saws. They are a closed belt with teeth. They have a lot of their own, characteristic only for them, merits. Band saws leave the cutting width much smaller than circular tools: if this fact is possibly insignificant when cutting budget wood, then when cutting elite metal and cutting valuable wood species it is critically important. With their help, you can cut absolutely any workpiece. In addition, the band saws perform well. provide high quality of the cut surface. Reducing chip waste due to their use is an obvious thing. However, in order to consistently experience all the above advantages of working with the tool in practice, it is necessary to take a responsible approach to its maintenance. Sharpening of band saws, as well as their distribution should be done efficiently and in a timely manner.

The price of sharpening band saws in specialized offices is usually low, but the speed and literacy of the work is not always pleasing. Is it possible to cope with the task with your own hands? Of course, if you know how to sharpen band saws correctly and have the necessary tools.

How to sharpen a band saw correctly?

It has been proven that over 80% of tool breaks occur due to non-compliance with the rules for sharpening band saws. The need for manipulation is determined visually. by the appearance of the teeth themselves or the condition of the cut walls (an increase in surface roughness).

Wheels for sharpening band saws are chosen depending on the hardness of the teeth. For sharpening tools made of tool steel, turn to corundum wheels. Bimetallic saws require diamond or borazon samples. The shape of the grinding wheel for band saws should be determined based on the parameters of the tool. It can be profile, cup, flat, disc-shaped.

Before starting work, it is recommended to let the saw hang in the inverted state for ten to twelve hours.

Requirements for sharpening band saws with your own hands:

ensuring uniform metal removal along the tooth profile;

exclusion of excessive pressing of the circle (this can lead to annealing);

ensuring the preservation of the height and profile of the tooth;

mandatory presence of coolant;

control of the absence of burrs.

The standard instruction for sharpening band saws states that sharpening should be done either on the front surface of the tooth, or on both the front and back. But this is theory. In practice, many professionals, and even folk craftsmen, “perform” it exclusively on the back surface. so, in their opinion, it is more convenient.

In general, despite a lot of rules and requirements, these tools are quite unpretentious in terms of sharpening. You can work with them, both with the help of a special sharpening device for band saws, and manually; apply for processing circles of different shape and material, etc.

Before sharpening a band saw, you need to familiarize yourself with the main methods of performing this operation.

Full profile sharpening

It is of the highest quality and is produced on an automatic machine. An elbor circle, precisely matched to the shape, goes through the entire interdental cavity in one motion, together with the corresponding surfaces of the adjacent teeth. Obtaining angular shapes at the base of the teeth is thus excluded. The only drawback of such a sharpening is the need to have a certain number of circles at the constant disposal for “multi-profile” saws.

Sharpening the edges of the teeth

Can be carried out on a professional machine or manually.

If the preference is given to the machine, then you should, again, choose the circle correctly. usually these are flat samples. In general, it is recommended to turn to specialized sharpening equipment only in cases where the volume of work is large enough. Occasional “home” manipulations are best done manually. with the help of an engraver or on a conventional machine. When working for safety reasons, it is imperative to use a mask or goggles.

Tips from professionals

In the case of sharpening the band saw with a machine, before starting work, you must make sure that the position of the sharpening disk relative to the tool is correct.

2. It is very important to remove such an amount of metal from the sinuses so that all microcracks are guaranteed to be eliminated.

3. If the tool “functioned” without quality maintenance longer than the manufacturer admitted, the amount of metal removed in one sharpening should be increased.

4. Always use a new tool as a reference to check the sharpening results.

5. Saw tooth shape is a parameter developed and verified over the years. Therefore, it is a huge delusion to hope that the tool will cut like clockwork, regardless of what you do with the teeth.

6. Subject to operational requirements, the band saw will serve you conscientiously until its width is reduced to a figure equal to 65% of the original value. The width decreases, naturally, in the process of regrinding.

7. There is a completely absurd recommendation that there is no particular need for deburring after processing. If you “listen” to it, then the appearance of microcracks in the canvas is guaranteed.

8. After work, the band saw should be immediately cleaned of resin and sawdust, and thoroughly examined before sharpening. Otherwise, the risk of clogging of the grinding discs is extremely high. And this inevitably entails a “hack” sharpening procedure.

How to sharpen a band saw to cut up to 100 cubic meters!

Entirely and immediately

If you carefully read how the work is going in the first way, you should have understood how difficult it is really to sharpen the saw with high quality.

There is constant talk that it is impossible to cut quickly and well with narrow band saws. Saws break quickly. To prepare them correctly, it is almost impossible to find a sharpener. The exit lumber produces a large wave, which negates all the benefits of a thin cut.

So, in order to radically solve all these problems at once, Wood-Mizer proposed a method not for sequential grinding of each tooth of a band saw, but at once for the entire tooth profile with just one entry into it of a special profile disc.

In this way, three main problems are solved at once:

- There is no need to look for a highly qualified sharpener. almost any person can sharpen a saw in one pass with factory quality on such a machine. He only needs to bring the blade to the saw. The machine will do the rest by itself, which makes it possible to eliminate as much as possible the influence of the human factor on the quality of the result. 1 mm. Further sharpening goes as usual.

- Band saws work two to three times longer, since the saw along the entire length is obtained with a completely grooved and absolutely identical profile of each tooth without burns, microroughnesses and scratches, that is, without stress points.

- The sawmill can work at its maximum performance, since the saw along the entire length is obtained with the same front and rear angles on each tooth. But, despite all the advantages listed, this method of sharpening was practically not used for a long time on sawmills.

This happened for the following main reasons:

- Very high price. Therefore, such a machine was bought mainly by service centers.

- Not very convenient technical solutions for the sharpening process itself. A warm room was required, a special oil, only with which a weak oil pump could work. This oil, with intensive sharpening, began to burn, so a mandatory hood was required and much more.

- But the biggest limitation was the inability to sharpen the profiles of band saws other than Wood-Mizer, manufacturers, since Wood-Mizer made profile blades only for its own saws. There were no other manufacturers of borazon grinding discs then.

Cheap group. Some manufacturers of classic grinding machines simply change the phases of movement on the cam. Now the disc no longer moves along the tooth, but only up and down. This gave them the opportunity to sharpen the entire tooth at once when installing a profile disc. But none of them understood that to sharpen the saw with a profile disc, it is necessary not only to change the phases of the cam movement, but also to make the entire machine according to a different class of accuracy. This has already caught many of those who turned to us for help. Therefore, I want to warn right away about the pointlessness of purchasing such machines. The worst thing for a disc is machine backlash. If they are (and they are on all ordinary sharpeners and, accordingly, remain on those sharpening machines that simply, with the help of another cam, try to remake them for working with CBN discs), then the disc begins to unpredictably hit either the front edge or the rear, and, accordingly, break the profiles of the saw teeth. Then, the already sharp tips of the teeth begin to cut the disc, several times reducing its service life.

Backlash can spoil the disc after 500 m. This is what happens with those who have already purchased such machines. At first, sharpening goes well, but very quickly an expensive grinding wheel becomes inoperative (it simply cuts off the front part to the base or cuts through the risk). You need to buy a new disk, which is already becoming economically unprofitable.

In fig. 3 shows the phases of motion of the profile disk. It should fit into the profile of the tooth all at once and sharpen with the entire plane. The thickness of the applied elbor layer is only 0.25 mm. But this layer is quite enough for long normal work. If the front part of the disc, when entering the profile, cuts into the apex of the tooth (Fig. 4), then the sharp cutting edges of the teeth puncture the risk relatively quickly in the coating or even tear it off in this place completely to the base, making the disc inoperative. In this case, there is also a breakdown of the tooth profile.

Dear group. These are the manufacturers who simply copied the Woodmizer machine. At the same time, they obtained the machine at the price of the original, and the workmanship is the same or even worse. With this option, it seems to me, it is better to purchase a verified original. However, it’s up to you to decide.

A machine for sharpening band saws with a borazon full-profile circle. This machine stands for sharpening in our service center.

Sharpening in this way is especially relevant when the saw is working on band-dividing machines, since the saw there, unlike the sawmills, works all the time, without stopping, and any untouched stress points there affect much faster.

However, this method of sharpening is now already economically profitable when preparing a band saw even on one sawmill.

Bandsaw Blade Sharpening the easy way

Here is a rough economic calculation of payback provided to us by the owner of one of the sawmills.

- The salary of a sharpener is about 10-15 thousand rubles a month. It takes a full day to prepare 10 band saws per shift.

- Small saw resource. sawing about 15-25 m 3 round timber into edged lumber.

- With a poor or average quality of saw preparation, the productivity of a sawmill for cutting wood into edged sawn timber is usually 0.2-0.5 m 3 per hour of round timber, that is, approximately 100 m 3 of round timber per month.

- On average, five band saws are consumed per month. With an average price of a saw of 800 rubles, the cost of them will be 4000 rubles.

- The average cut of 20 m 3 is multiplied by the number of saws (5 pcs.), We get 100 m 3.

- Let’s take the average profit from 1 m 3 of edged lumber equal to 400 rubles, with an average or poor surface quality and, accordingly, not the highest price for lumber.

Profit for the month will be 400 × 100 = 40 thousand rubles.

Total: net profit for the month will be 26 thousand rubles per month: 40 thousand rubles. 10 thousand rubles (sharpener salary). 4 thousand rubles (cost of saws).

And how much nerves it will cost, only you know!

- It takes 60-90 minutes to prepare 10 band saws per shift. No additional person required. Saws can be easily prepared by the owner of the sawmill or the frame operator.

- Saw resource. sawing approximately 40-60 m 3 and more round timber into edged sawn timber.

- The productivity of a sawmill for cutting wood into edged sawn timber is usually 0.8-1 m 3 per hour of round timber, that is, approximately 200 m 3 of round timber per month.

- On average, five band saws are consumed per month. With an average price of a saw of 800 rubles, the cost of them will be 4000 rubles.

- Let’s take the average profit from 1 m 3 of edged lumber equal to 450 rubles, with good surface quality and, accordingly, a high price for lumber.

Profit for the month will be 450 x x 200 = 90 thousand rubles.

Total: the net profit for the month will be 86 thousand rubles: 90 thousand rubles. 4 thousand rubles (the cost of saws).

With quiet production!

We get the difference in profit for the month: 86 thousand rubles. 26 thousand rubles = 60 thousand rubles.

The difference in the price of the machines: 75 thousand rubles. 25 thousand rubles = 40 thousand rubles.

Thus, already in the first month of work, you pay off the grinding machine with a profile wheel and then only increase your profit.

The calculation was made approximately. But it relies on real work experience. You can do your specific calculation yourself.

In previous publications, we began a conversation about the specifics of the acquisition and subsequent operation of sawmills, band-dividing machines for the production of moldings and band-sawing machines for furniture enterprises. We dwelt in detail on the consideration of the classical method in which the teeth are sharpened with a sharpening wheel. And they reflected two factors that affect the quality of sharpening. technical and instrumental. The third factor, the last on the list, but essentially the main one, is the human factor.

When choosing a person to work as a sharpener, first of all pay attention to his character. Hot, explosive, trying to do everything quickly, a person will never become a good sharpener. Here you need a calm, attentive, diligent, responsible person who can perform monotonous work for a long time. But even this is not enough. Good sharpeners are obtained only from those who can literally feel the saw and adjust the sharpening machine only by ear. It is not for nothing that the people say that one must be born a good sharpener. And indeed it is. Since it is practically impossible to simply sharpen the band saw in this way mechanically, for the reasons indicated above and below.

Now we will show what exactly needs to be done by the sharpener in the process of work.

The sharpening process must begin with an inspection of the machine:

- It is necessary to check the alignment of the grinding wheel and the plane of the band saw so that they are strictly perpendicular. Otherwise, the tooth will be sharpened with a bevel to the side.

- Set the grinding wheel to the desired angle in relation to the plane of the saw, that is, set the rake angle of the tooth along the limbs of your machine. Since these dials never correspond to reality, after sharpening the saw, check the obtained real angle with a protractor. If it does not suit you, slightly change the angle setting in the required direction. Sharpen the saw again and check the resulting angle. And so on until you get the required angle. It is advisable to do this with a circle with great hardness, so that during the installation the circle does not lose its shape. Otherwise, you will have to edit it and thereby knock down the presets. After you get the desired angle on the saw, take a scribble note on the machine. It will be useful to you later for new reinstallations at other angles.

- All moving parts must have minimal backlash, and it is better that they are not at all, otherwise the profile of the teeth and the grinding wheel will break down rapidly.

- The coolant must be supplied in such a way that the entire tooth being sharpened is washed, otherwise the part of the tooth where the liquid does not enter will be set on fire.

- The grinding wheel must be set of the correct size and sufficient hardness so that its profile does not change at least one full pass, otherwise the saw will have a different tooth profile along its entire length.

- During sharpening, you cannot change the adjustments of the grinding wheel until a full pass has been machined, otherwise a different profile will turn out at the transition points and during subsequent passes the wheel will either burn the profile or pass without touching it.

The grinding wheel is adjusted with two screws:

- a pusher screw that regulates the cutting along the leading edge and the passage of the tooth profile;

- plunging screw.

After preparing the grinding wheel, set up the band saw and, by scrolling the wheel by hand or at minimum feed, check how accurately it follows the profile. Profile the circle again if necessary.

After finishing work, it is necessary to clean the saw clamping mechanism, the coolant tray from dirt, metal filings and rust; check the fluid level and add it if necessary; wipe the whole machine.

The main reason for incorrect sharpening of the band saw is the loss of its shape by the sharpening wheel.

If a technical problem can be solved with the help of high-quality manufacturing of the machine itself (for example, Vollmer produces very good machines), if the tool problem can somehow be solved by the correct selection of the grinding wheel, then the problem of forming the profile of the grinding wheel cannot be well solved even theoretically.

Only very experienced sharpeners or people with an inner instinct can come close to understanding and as accurately as possible profiling the end of the grinding wheel. Let me explain this with an example. Draw a horizontal line on a piece of paper. Now from this mowing line to the right side, draw two vertical mowing lines, one at an angle of 10 °, and the other after 3 mm at an angle of 40 °. Now connect the left line to the horizontal line through a 1.5mm radius and the right line through a 1-2mm radius. Do this several times and check with the protractor what you get. For clarity, you can combine these sheets. Please note that a data discrepancy of only 0.5 ° already leads to inaccurate profile cutting. And inaccurate connection of the left straight line also leads to a change in the saw pitch. Now imagine that the sharpener should do all this not on paper, but on a rotating circle, where it is even more difficult to maintain exact dimensions. But it is not enough to form it once. It is necessary that when re-sharpening after sawing, the profile of the wheel end is exactly the same as in the previous sharpening, which is practically impossible. Therefore, it is not so important what quality around you are sharpening. Even if you have a very good circle and you can grind a set of band saws for a whole shift with it without additional profiling, you will almost never be able to repeat exactly the same profile of the wheel end with the next sharpening, which means that you will not be able to accurately grind the profile of the saw teeth after its bluntness. Now you understand why the exact formation of the end face of the profile of the circle is not only difficult, but extremely difficult. In order to somehow facilitate its solution, you can sharpen with bakelite reinforced circles 3-4 mm thick. But it is difficult to find them of the required workmanship.

Therefore, the profile of the circle must be monitored very carefully. Otherwise, this leads to the following changes in the band saw body:

- A change in the radius at the base of the tooth, which entails a change in the step and the impossibility of normal sharpening of the saw already on the next pass. The circle begins to cut unevenly into the front edge without touching the back one, or vice versa, that is, it becomes impossible to grind the full saw profile at once. Already in two or three passes, the sharpener tries to grind at least the cutting edges of the teeth, while a microhump or microdeep appears at the transition point, which lead to the occurrence of microcracks, and microcracks that have already arisen during sawing are not removed, which leads to premature rupture of the saw along the body.

- Changes in sharpening angle, tooth height, cavity shape, which affect the performance of the sawmill and the quality of the resulting sawn timber.

The grinding wheel should look as shown in fig. 1a. Thickness. 5-8 mm. But in practice, working with such a profile is very difficult. We recommend using circles with a profile as in fig. 1b. Thickness. 3-4 mm. Then the sharpener will not need to very often form the profile of the grinding wheel, but only occasionally slightly correct it. This greatly simplifies the work of the sharpener.

As will be shown below, only 3-4 mm of grinding wheel thickness can be involved in the sharpening process. thickness is only needed if you have the perfect machine. But this does not exist in nature. And also if you want to sharpen at accelerated tooth feeds, then the circle will not bend and bend. But at the same time, you are almost guaranteed to get large risks and burns and thereby greatly shorten the life of the saw, and you can hardly cut well. The cutting time of one whole pass of a 4 m band saw should be 10-15 minutes. At least two passes are needed: the first is sharpening, the second is finishing to remove the marks.

In practice, it is rarely possible to sharpen a saw well in one pass. often, two or three are needed. So, if now the sharpener tells you that in 15 minutes he will bring the sharpened saw, you can imagine what quality it will be.

Possible violations of the shape of the end of the grinding wheel and the resulting profile of the saw tooth are shown in Fig. 2.

Under numbers 1-7, the red dotted line shows the exemplary profile, the solid line. the resulting.

- Correct end shape. ideal for the resulting tooth profile.

- Sewing while sharpening the front radius. There is a change in the radius of the hollow, followed by a change in the pitch of the saw.

- Left side radius too small or missing. During sharpening, the front tooth radius is not formed. This leads to a change in the saw pitch, as well as to an increase in stress during sawing at the root of the tooth, which leads to the occurrence of microcracks and an accelerated rupture of the band saw in this place. This shape of the end of the circle can be obtained during the initial formation or in the process of sharpening.

- Incorrect preparation of the right side. Too little filmed. During sharpening, the cavity will increase, the tooth will be shortened and set on fire at the exit. This state of the grinding wheel can also occur during the sharpening process.

- Incorrect preparation of the right side. Too much filmed. During sharpening, the stroke of the grinding wheel will be less than the cavity, that is, the back of the tooth will not be grinded.

- Incorrect preparation of the right side. the angle is greater than the posterior angle of the tooth. During sharpening, the back of the cavity will not be machined, since the right end of the circle will abut faster against the back of the tooth than the right radius will reach. The tooth will be shortened and ignited at the exit.

- and. Incorrect preparation of the right side. the specified angle is less than the posterior angle of the tooth. The circle follows the profile of the tooth almost exactly.

As you can see from the examples above, it is almost impossible to ideally prepare a grinding wheel due to problems with the right side. Therefore, you must try to shape the working surface as shown in paragraph 7a. The circle of the required hardness with such a profile will allow the sharpener to grind several band saws before straightening, the number of which depends on the thickness of the material being removed. But at the same time, you still need to follow the work of the circle, since as the end of the circle is grinded, the angle of the right side will increase and the circle must be re-profiled.

If you immediately put a circle with a thickness of 3-4 mm (paragraph 7.b), you will practically not need to profile the right side, you only need to follow the left side, and this greatly simplifies the process of forming the profile of the end.

It is also necessary to remove such an amount of metal in one pass so that there is no cauterization of the body or the cutting edge of the band saw. Sometimes even with a small removal of the metal, blackness still appears. In this case, it is necessary to clean the grinding wheel with a straightening pencil from adhered metal particles and grind the saw again.

You can not leave also big risks, you must definitely go through another circle and grind them.

So, it is imperative to give the end of the grinding wheel the correct shape and sharpen the band saw only along the entire tooth profile, using a harder wheel, remove as little metal as possible in one pass so that burns do not get burned, sharpen the saw in several passes, so that in the end there were barely noticeable white risks. The profile of the tooth should be the same along the entire length of the saw and match the sample.

The saw must be installed on the machine clean and stainless. Otherwise, the push rod may not have enough force to pull the saw and the grinding wheel will hit the tooth. The tooth will be damaged. When cutting hard, the circle can crack.

The saw band must be tightened all the time when sharpening, and the tightening mechanism must be clean. The clamping force should be such that the pusher pushes the tooth with slight tension, but so that the engine does not slow down. If the saw is loosely clamped, it can move backward behind the outgoing pusher or forward from the force of the grinding wheel. The result will be the same as in the previous paragraph.

If you have doubts about the ability of your sharpener to sharpen the band saw correctly, you can test it for a few minutes.

You need to take any saw, prepared for work, and look at it from above the tooth, where the grinding wheel passed. The end should be the same silver color. If the cavity is darker in color, then it has not been pierced. There should be no blackness at the end. If there is blackness, then when working in the body, microcracks rapidly appear in these places, which leads to a rupture of the band saw. over, the cutting edge should not be set on fire, since in this case it will instantly become dull and the saw will stop cutting, that is, a wave will go. Only barely visible white risks are allowed.

You also need to check the shape of the tooth using the sample, which should be at the sharpener. Such a piece of tape can always be obtained from the company from which you purchased the tape.

If you are already tired of reading how to sharpen correctly in the first way, and you just want to work and make a profit, without constantly thinking about all these problems, then only the second way of sharpening a band saw is suitable for you.

Sharpening method in which the bands are cut 2 times more lumber!

Recommendations

Sharpening discs

Confusion sometimes arises as to how borazon differs from elbor.

Borazon. technical cubic boron nitride (b-BN). was first obtained in 1957. In 1969, General Electric registered the Borazon trademark for a crystal.

Elbor is technical cubic boron nitride (b-BN). Elbor was synthesized in 1959 by a team of scientists from the Institute for High Pressure Physics (IHPP) of the USSR Academy of Sciences. Since 1964, industrial production of Elbor and tools from it has been organized.

Thus, it is one and the same material, but obtained in different ways in different countries. It is believed that the structure of Russian elbor has the best grinding properties.

To date, working with disks from different companies, we have received an average resource:

- Wood-Mizer. ≈5-7 km;

- Polish, Turkish and other unknowns. ≈2-4 km;

- Russian-Ukrainian production. 7-10 km and more.

I want to repeat what I started this article with. Any machine tools are bought to make a profit with their help. Everyone wants to supply equipment and work without unnecessary problems. But rarely does anyone really know what they will have to face after installing the main equipment. After reading this article, you have a complete understanding of all the pros and cons of the two ways to sharpen a band saw. Now, based on this knowledge, you can already make the right choice on your own.

We offer you to purchase a trial batch of band saws with subsequent sharpening in our service center, this will give you an understanding of how band saws work after sharpening with a borazon wheel, compare them with your sharpening and not buy a seemingly expensive and modern machine.