Tarpan motocultivator change oil in gearbox

All about Tarpan cultivators

Today, domestic and foreign manufacturers offer a large number of various auxiliary equipment to help farmers and dacha farmers. Among this list it is possible to distinguish cultivators of Russian production “Tarpan”, which are actively used by Russian farmers, as well as successfully sold abroad.

Construction and operating principles of ≪Tarpan≫ units

The high-quality Honda, Champion and Zongshen engines ensure high machine performance.

Advantages of cultivators:

- The high-performance worm gear.

- The engine is cooled by the air filter and the carburetor lasts longer.

- Attachments are provided.

- All controls on steering wheel.

- Height adjustable steering wheel.

- It is convenient to change the angle of tilt or turn the cultivator with the help of rubber-coated handles.

- Clutching is quicker due to reliable spark plugs.

- The snow blower separates into 2 parts and is easy to transport in the trunk of a passenger car.

About the producer

Tulamashzavod is a large association of various companies, headed by a joint stock company with a number of subsidiaries.

The main area of activity of these companies is to provide the defense industry with various products, as well as manufacturing of various products for household needs. Territorially the enterprise is located on the site of the former Baitsurovsky factory, organized in 1879.

It specialized in production of various iron and copper products.

In 1912 the factory became a part of the Imperial Tula Arms Factory.

OOO Tulamash-Tarpan, which is a subsidiary of Tulamashzavod, specializes in manufacturing small-sized agricultural machinery in our country.

The company has quite a wide representation in the regions and neighboring countries. about 70 dealer centers. This wide distribution allows Tarpan machinery to increase its sales every year, as well as popularize it in other countries.

Motor blocks Tarpan. a real Russian product, which combines unconditional quality performance and affordability.

Read more about Tulamashzavod at

Spare parts

Weed whacker

Can be used with these models: 03, 04, 07. The part itself is made up of the frames and mouldboards that are adjusted by means of a beam with holes.

Hiller must be used with a skimmer or a tine.

Only all of them together create the desired pulling power. Can be installed in place of the depth control. It is not always easy for a beginner gardener to distinguish between a classic rocker and a plow, however, they are significantly different: a rocker is a symmetrical machine that is equipped with two wing-shoulders.

During operation, these wings are able to spread the ground on the sides. right and left, depending on the course of travel. The plow cannot be called a symmetric plow. It’s equipped with a single mouldboard and only shifts soil to the left or right.

“Tarpan” cultivator contains a lot of useful information on the choice of equipment, its care and all the necessary parts. There are models where the wings are replaced by two spherical disks. These are called the disk spuds. They lift the soil well and perfectly clear the plot from weeds.

Groomers

Model 260h80 is used for “Tarpan 03, 04”, and 400h170 or 500h170 is used for the “07-01” model.

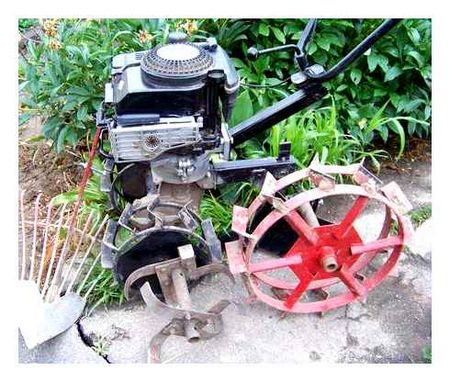

Grousers or wheels, made of metal with hooks, are used to improve the traction of the device with the soil.

The parts vary in size and fasteners. Are made of a square profile, regardless of the diameter, have welded hubs (polyhedrons or round holes of different diameters) or have holes to attach the hub.

When selecting trailing shoes, you must consider the model of the power tiller and what you want to do with them.

Installation of attachments for cultivator ≪Tarpan≫

Different brands of attachments are interchangeable.

Mowers

≪Strun mower-adapter for ≪Tarpan is designed for mowing grass up to 20 cm. Mower blade successfully manages open areas and hard-to-reach places. Rotary mower is no less popular. Attached rake makes it easy to collect hay and use it for its intended purpose.

МОТОКУЛЬТИВАТОР ТАРПАН ОБЗОР ЗАМЕНА МАСЛА РАБОТА

Snow blowers

Snowplow attachment to ≪Tarpan≫ cultivator can be combined with machines of other brands. ≪Tarpan SNU snow blower is operated manually with the help of levers. Can shovel snow up to 25 cm. Working width of 1 meter.

Many attachments are available for the ≪Tarpan≫ cultivator

Snowblower can be equipped with a brush, dozer blade, blades. Capable of throwing snow to the side up to 5 m.

Shovel blade

Simply rake trash, level the site, clear snow with a shovel-drow for cultivator ≪Tarpan≫. Blade rotation is adjustable.

Frame with wheels

Transport wheels attached to the frame make it easy to move the cultivator.

Couplings

Cultivator hitches are used for attaching implements to the cultivator. They can be rotary or U-shaped. The swivel allows you to maneuver when working.

Potato digger and potato planter attached to cultivator ≪Tarpan≫

The potato planting canopy looks like a big cone-shaped funnel in which the planting material is placed.

The most popular potato harvester is the screen harvester. It grabs the root crops together with the soil and, rattling, sifts through the contents, leaving the potatoes on the soil surface.

Reversible plough

Reversible plough is used for plowing in virgin and heavy soils. It is mounted at the back of the machine.

Hillers for soil

Tiller tillers for the ≪Tarpan≫ cultivator come in single-row and disc types. Attached without couplings.

Cutters for loosening and plowing

The ≪Tarpan≫ cultivator comes with active rotary hoes for loosening the soil. There are also so-called ≪goose feet≫. cutters that till the ground instead of a plow. They are available as an option or made by craftsmen.

Sometimes it may be necessary to make some adjustments when using a cultivator

Soilers

It is hard to imagine hard tillage without tines. Two of them are included in the delivery set.

Overview of model range

Tarpan mowing cultivators compare favorably with other similar models due to their assembled construction the machine can be conveniently transported to the place of operation in disassembled condition: power unit and gearbox component.

Modern cultivators are equipped with Honda and BriggsStratton engines that are reliable, economical, and require minimal maintenance. There are also models in the family of Tarpan motocultivators with Chinese engines Zongshen and Loncin, which allows producing competitive machines at budget price.

Zongshen ZS 168 FB Engine Honda GX160 Engine Loncin G200F Engine Briggs Stratton RS950

The first Tarpan-01 was introduced in 1993. The machine was equipped with a 6.2 liter two-stroke engine.с. Despite various design flaws, it was quite popular. A few years later a new modification Tarpan-03 was developed, which is still in demand today.

Tarpan TMZ-MK-03

The machine is equipped with American engine of 6 liters.с. with a service life of 1000 engine hours. Thanks to worm gearbox it provides 1 speed. Cultivator is designed for agricultural work on all types of soil. Cutters provide processing of strips with working width of 35-100 cm.

Thanks to the low weight of 45 kg, the machine is very maneuverable. Ergonomic handlebar can be adjusted to the operator’s height and handle length, it is possible to operate the cultivator from the side without trampling over the newly ploughed area.

Technical Data

| Weight, kg | 45 |

| Dimensions (ДххВ), mm | 1300x700x1060 |

| Warranty, months | 36 |

| Cultivation width, cm | 30-70 |

| Motor | BriggsStratton I/C 6,0 |

| Oil volume in reducer, l | 0,6 |

| Cultivation depth, cm | 20 |

| Number of gears | 1/0 |

| Reducer | Single-stage, worm type |

| Drive | gear transmission |

| Type of grip | dry, automatic, centrifugal |

| Cutter speed, rpm./min. | 120 |

| Type | BriggsStratton I/C 6.0 with vertical shaft |

| Fuel | petrol |

| Engine displacement, cm3 | 190 |

| Cooling | active air |

| Fuel tank, l | 3,8 |

| Power, l.с. | 6 |

| Start system | manual |

Motor cultivator Tarpan TMZ-MK-031

Cultivator belongs to the light group. its capacity is 3.5 liters.с., Weight only 28 kg, working width 50 cm to a small depth of 14 cm. This modification is convenient when working on small plots of land, in greenhouses, in the garden. The machine is easy to maneuver and very comfortable to operate thanks to its low weight.

Technical Data

| Direction of rotation of the tillers | direct |

| Number of cutters | 4 pcs. |

| Working width | 50 cm |

| Cultivation depth | 14 cm |

| Diameter of cutters | 240 cm |

| Engine power | 3.50 л.с. |

| Engine type | petrol, four-stroke, cylinders: 1 |

| Gear type | worm |

| Number of gears | 1 forward |

| Type of gearbox | single-stage |

| Type of grip | belt |

| Weight | 28 kg |

| Dimensions, LHHW | 1210x510x1020 mm |

This small but powerful machine demonstrates its great functionality in this video review:

Cultivator Tarpan TMZ-MK-04

Lightweight, compact unit with BriggsStratton 6.05L engine.с. designed for medium size plots. Very easy to operate.

Technical specifications

| Class | light |

| Type | cultivator |

| Tillage width | 56 cm |

| Number of cutters included | 4 pcs. |

| Direction of rotation of the tines | direct |

| Cultivation depth | 20 cm |

| Engine manufacturer and model | Briggs and Stratton 12/802 |

| Engine type | Gasoline, four-stroke, cylinders: 1 |

| Engine power | 4.45 kW / 6.05 л.с. |

| Engine capacity | 190 cc. See |

| Gearbox type | worm |

| Number of gears | 1 forward |

| Type of gearbox | single-stage |

Electric cultivator Tarpan 0,7-2,2

This cultivator is equipped with a 2.2 kW electric motor. Despite its low power it has enough mass to cultivate large areas. Tillage width 35-70 cm, depth 20-30 cm. The machine can be rationally combined with various attachments, and its options are limited only by the length of the electric cord.

Oil change in the power tiller

After about 100 hours of engine use, the oil in the engine must be changed; sometimes this procedure must be done after 50 hours. Only use the type that meets all requirements and conditions of use. So what oil to pour in a single axle tractor?

The procedure for changing the oil consists of several operations:

- set the single axle tractor horizontally;

- using a strong screwdriver remove the plug on the tank drain;

- pour the contents into a prepared container (volume must be at least 2 l), the whole process will take about 20 min.;

- screw back the drain plug of the tank;

- pour the right quantity of oil for power tillers into the gearbox; then close the hole. Be careful when filling with oil so it does not drip down the walls.

The most suitable oil for use is 10w30. If you use 4-stroke oil for your powerpack it is a good idea. Thanks to its anti-corrosion properties the engine will last much longer. When used in combination with special additives the effect of work is intensified.

Sometimes users buy unlubricated power tillers, in this case it is necessary to fill them with fresh lubricants before using them. To make the right choice, you must use quality, reliable, and suitable oil for your motor-block. Particular attention should be paid to the viscosity (the indicator is indicated on the label). According to this criterion, the oil with marking SAI, API. But first you should carefully read the manual, which will clearly indicate the recommended lubricant variation.

Gear oil for your motorblock varies, and its quality almost always depends on price. But in any case, its high cost will pay off, because the engine repair will cost a pretty penny, and it will also become a big trouble.

It is important to use oil from reputable manufacturers if possible, their quality lubrication will protect the gearbox of your motoblock. The main thing in this matter is not to get caught on a fake. When choosing your oil pay attention to its properties, and also what time of year it is intended for.

Tarpan motocultivator is a universal small-sized machine intended for mechanization of the hard physical labor to cultivate the soil at homestead plots.

Recommended area to be cultivated up to 0,2 ha.

Tarpan mowing cultivators are produced in Tula city at Tulamashzavod plant.

A distinctive feature of this mowing cultivator is the ability to disassemble it into two parts and fit into the trunk of most sedans.

Transportation of MK is allowed after disconnecting power unit 1 (see technical data of the EA). Fig. below) from executive unit 2. For this purpose it is necessary to loosen hinged bolts 3. When transporting the MK it is necessary to arrange it so that to exclude pouring out of oil from the reduction gear (through the filler plug opening), from the engine crankcase and the rests, fuel from the fuel tank.

Technical characteristics of Tarpan MK-03 cultivator with Honda engine, briggs stratton

| Basic parameters | Value | |

| Overall dimensions, mm, not more (control handles folded down) | length 1300 (760) width 700 height 1060 (760) | |

| Weight, kg | 45 | |

| Working width, mm | 560 | |

| Cultivator cutter diameter, mm | 320 | |

| Output, ha/h (at normal soil and ripping depth 180 mm) | 0,06 | |

| Loosening depth max., mm | 200 | |

| Limit tilt angles at work, deg., longitudinal and transverse. not more | 15 | |

| Motor | briggs stratton | Honda |

| Model | 12j802 | GCV-160 |

| Type | 4-stroke, carburetor | |

| Working volume, cube. see. | 190 | 160 |

| Max. power, l.с., not less | 5,5 | 5.5 |

| Fuel tank capacity, l | 1,1 | |

| Volume of filled oil, l | 0,6 | 0,55 |

| Fuel and oil according to engine manual | ||

| Hourly fuel consumption, l/h, not more | 1,1 | |

| Clutch | Dry automatic centrifugal | |

| Start | Manual operation | |

| Switching off | Remote throttle lever | |

| Gearbox | Single worm | |

| TAD-17I GOST 23652-79 worm gear oil. Permissible replacement gear oil grade SAE 90, SAE 75W/90, API GL-4, GL-5 | ||

| Volume of oil in gearbox, l | 0,35 | |

| Sound level at operator’s work place, not more dBA | 81 | |

| Correction level of vibration velocity on control handle, max dB | 118 | |

| Number of speeds | 1 forward | |

On the MC Tarpan is installed engine firm Briggs Stratton model 12j802 or Honda company model GCV-160

displacement: Briggs Stratton 190 cm3 ; Honda 160 cm3

What fuel and oil to fill in the Tarpan cultivator you can find out from the engine user manual or from the table in the manual.

Honda GCV-160 engine manual download

Engine briggs stratton 12j802 user manual parts catalog download (useful when ordering parts).

Manufacturer of Tarpan cultivators Tarpan Ltd. Tula, official website www.tulamash.ru/static/tarpan/history.html

Motor cultivator Tarpan instruction manual download

Tillage operations are performed by the MK rotary cultivator. Cultivator cutters as they rotate cut the soil layers, crumbling and mixing them, while causing forward movement of the MC.

The advantage of the rotary cultivator compared to the plough is better soil loosening, chopping and incorporation of weeds, as well as uniform mixing of organic and mineral fertilizers on the entire depth of cultivation.

Application of the MC is also recommended on clayey heavy soils, as it has a high torque on the shaft and grinds the soil well.

Tillage of virgin soil by milling is not recommended. This breaks the agro-technology of tillage.

MK Tarpan consists of the following main parts ;

- Power unit including engine, coupling device, centrifugal clutch, steering

- Operating unit including worm gearing, rotary cultivator left, rotary cultivator right, depth regulator, bracket, protective hood.

Additional hinged implements and accessories for widening of furrow preparation, weeding, weeding row spacing and other operations are available separately and designed to expand the functional capabilities of the power tiller.

Cultivator Tarpan attachment

Designed for mowing lawns and lawn areas to a specified height. It is installed instead of an executive unit and connected to the power unit.

Mower Struna with working width 0,6 m is intended for cutting of the grass and weeds both on open areas and in hard-to-reach places near trees, curbs, fences. With a cutting head speed of 3,800 to 4,600 rpm. Grass is easily cut and tossed aside. Instead of blades the mower is equipped with a polypropylene nap string. Easily disassembled into power unit and working body, the mower can be freely transported in the trunk of the car.

Hiller used with MK Tarpan-03, 04 and MB Tarpan-07 consists of frame and mouldboard, adjustable by means of slat with holes. Is used for hoeing crops, cutting ridges and furrows, making furrows. Hiller should be used together with threshing blades, which create the necessary traction power.

Sliders are used with MC Tarpan-03, 04 and MB Tarpan-07 consisting of tines and blades fixed on a hub, intended for weeding and loosening soil. Minimum width of hoeing strip 350 mm. Sliders are installed on gearbox output shaft of MK instead of rotary cultivators.

Cutters as they rotate, crush and mix layers of soil, at the same time causing forward motion of the rotary cultivator.

260х80 blades are used with MB Tarpan-03, 04

Transport frame with wheels is used with MK Tarpan-03, 04

Protective disc is used with Tarpan-03, 04 and MB Tarpan-07

Goosefoot cutter is used with Tarpan-03, 04

Operating principle of MK: MK shaft is driven by a gearbox from the engine, on which tillage cutters of a rotary cultivator are installed. Cutters rotate to loosen topsoil and simultaneously move MC forward. MK design allows fast separation of power unit 1 from executive unit 2. To do this, release the hinged bolts 3.

Power unit includes a unit with 4-stroke engine 1, coupling device 2, clutch 3 and steering 4

MOTOR. For the structure of the engine, see the Engine Manual.

Steering control system allows to adjust position of levers in vertical and horizontal planes. It enables to cultivate beds without trampling the soil when steering control is turned horizontally. For ease of transportation (size reduction), the steering wheel should be turned towards the engine.

The engine remote control unit allows you to change the engine speed with the control lever 2 and stop the engine by pushing the lever down as far as it will go.

The centrifugal clutch transmits engine torque to the gearbox when the engine reaches the required RPM. Clutch provides MC for clutchless starting.

WARNING! Do not start the engine while the power pack is not coupled with the gear unit or other implement in order to avoid damage to the coupling parts.

It is RECOMMENDED to drop 1-2 drops of engine oil once a season between the pad axle and the bushing 4 (two places) used in the engine to improve clutch performance.

Gear unit (Fig.5) single stage, worm, with an oil bath. The gear housing has flanges with holes for mounting the transport device and other attachments.

Cultivators 1, 2 left and right are installed on the gearbox shaft and fixed with axles with locks.

stand behind the handlebar and grasp the handles firmly;

Slowly actuate the control lever on the engine speed regulator and gently increase the engine speed;

when the engine has reached the desired RPM, the centrifugal clutch is automatically engaged, the gear shaft starts to rotate and the MK begins to move. The working depth of the rotary cultivator tines is set in accordance with the position of the depth regulation lever. which can be changed by repositioning it in the bracket through the holes in the regulator.

The depth of the tiller into the ground is adjusted by pushing the steering control. the depth regulator sinks into the ground and the forward speed is reduced. The deeper the regulator enters the ground, the lower the travel speed of the MC and the greater the working depth. If the MC does not move forward and the cutters dig into the ground lift it by the steering wheel.

If the MC is pulling to the side of the machined area, move the working MC to the opposite side. Turn the cultivator by tilting it to the right or left. ATTENTION! Maintain a sufficient distance between machines, depending on the steering length.

When turning, do not pull the mower towards you. When cultivating loose, light soils, do not allow the tillers to sink in completely, which would overload the engine. On heavy soils, work in several phases, each time increasing the working depth to create a good crumbling of the clods and a more even soil structure. Mow and remove vegetation before working in areas with high vegetation. When cultivating areas with plant residue, plant residue can wind up on the tines of the MK rotary cultivator.

Periodic cleaning of the tines. To reduce winding of plant debris on the cutters, you can use sabre-shaped blades, used on MK Mole, Salyut. During operation of the MC, blunting of rotary cultivator blades occurs, which impairs their penetration into the soil, reduces the working depth per pass, reduces productivity. Sharpen blades as needed.

Maintenance of the Tarpan cultivator

Maintenance hours and calendars should be observed depending on which of the following occurs first. In severe operating conditions more frequent maintenance is necessary.

Maintenance of the engine should be performed according to the Engine Manual”.

Types and frequency of maintenance

After the first 5 hours of operation change oil in the gearbox.

Every 5 hours or daily clean and wipe down the MC.

Checking tightness of engine connections for oil and fuel leakage. Checking fasteners. Check gearbox oil level.

Every 25 hours. or every season check and clean the clutch.

every 100 hours. or every year oil change in gearbox, lubricate control rod and control box.

Operation manual

Tarpan single axle tractor, whose operating instructions will be discussed below, has a very interesting feature. it can be easily disassembled into two component parts for more convenient transportation.

The hand pump sprayer is a tool for plant care, sprinkling and watering crops. The hand pump sprayer. irreplaceable helper in the garden.

On the streets of modern cities no one is surprised by various snow removal equipment. Follow this link to read all about the Champion 656 snow blower.

Today, more and more consumers are buying such an indispensable and important agricultural tool as a lawn mower. Here’s all about the most popular models of MTD lawnmowers.

One part of it includes a power unit consisting of a power unit, fuel system and controls. The second part is a geared unit consisting of a gearbox, gearbox, wheel or tiller, and two brackets. rear and front.

Changing the Gear Oil

On various Internet forums many people ask how to change oil in Tarpan power tiller? To begin with you need to drain the oil into a bowl, and then pour it into the gearbox to the optimal value (350 ml). In this case, the new oil is filled and the old oil is drained through the hole with a plug.

It is recommended to drain the oil right after finishing all works when the oil is still hot.

Many people are also interested in the question. what oil to fill in the gearbox in the engine block Tarpan? According to the instructions you should use SAE 90 oil in the gearbox.

Gearbox

As for engine oil, then the required brand of oil is specified in the manual to the engine itself (different models of Tarpan engine uses a different motor, so the oil will be different).

Replacing the oil seals

The oil seals in the gearbox of Tarpan motoblocks should be replaced if there are oil leaks from the gearbox. This should be done immediately, because if the gearbox leaks oil completely, all of its components will fail quite quickly, i.e.к. cannot be operated for a long time without lubrication.