How to cut mineral wool insulation

How to cut mineral wool?

The material has a fibrous structure, therefore, during cutting, small particles of glass wool fly in space. Therefore, the contact of hazardous elements on the skin and in the respiratory tract should be prevented.

Before cutting the insulation, the following conditions must be observed:

- The room must be well ventilated.

- In the process of work, it is mandatory to use protective equipment and special clothing. We are talking about gloves, respirator, mask, overalls and goggles.

- When the material is cut, it is recommended to wash your face and hands under cold water.

To ensure that as few glass wool particles as possible form in the air, a well-sharpened tool should be used.

The insulation should be cut without unrolling the roll.

Advice! It is best to cut the material across.

To get strips of cotton wool of the same width, you should cut the material right in the roll. If the cotton wool is in the form of slabs, then you need to cut them one by one.

In order for the strips of cotton wool, cut independently at home, to turn out even and the same, they should be clearly divided according to the marks. Also, you can use the ruler as a cut line.

When cutting, leave allowances at the edges. If it is a roll, then the indicator should be 0.5 cm, and if the plate is 2 cm.This cutting feature is needed so that the mineral wool element completely fills the required space.

Recall that the slabs of mineral wool are cut one at a time, and we cut the material in rolls without expanding.

The better to cut mineral wool?

Professionals use a special machine to separate canvases and rolls. But many ask the question: “What is the best way to cut mineral wool in slabs at home in order to save money?”

Important! To cut mineral wool, use a hacksaw for metal or wood.

In everyday life, an assembly knife is used to cut the canvas. This tool has one drawback, because of the small blade, it is difficult for them to cut thick slabs. Therefore, I recommend using a clerical knife only for thin sheets. If you do not comply with this condition, then the canvases may become unusable.

Cutting mineral wool with a knife

Best Tools for Cutting Mineral Insulation:

- A knife with a blade made of carbon steel. It is very easy to cut with such a product, in addition, its blade sharpens well and quickly. This knife needs a lot of care to avoid rusting. The basic rule of care is to wipe the blade after washing.

- A knife whose blade is made of stainless steel. There are teeth of different lengths on each side, so it is very easy to cut the mineral insulation of different sizes and thicknesses. The blade quickly plunges into the slab and cuts it efficiently. Sharp tip can even make indirect cuts.

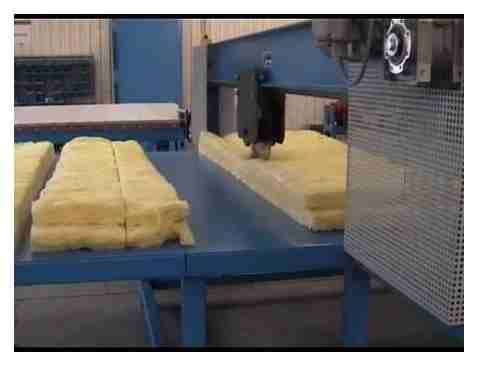

- Special machines. Such tools are able to cut the canvases along a flat mowing line and along a bend. This feature is very much appreciated in the industry. If you need to cut the cotton wool once, then there is no point in purchasing expensive equipment. the tool that is in the house will do.

Cutting mineral wool with a special saw

Note! Cotton wool scissors cannot be used.

For cutting cotton wool, it is advisable to use a special hacksaw for heaters or for metal. It is used to cut material that is less than 5 cm thick.

How to cut Rockwool Thermal Sound Insulation Slabs for Loft Attic Easily and Quickly

The blades of the tool you use to cut the cotton should always be well sharpened. In this case, the fibers from the cotton wool will be stretched to a minimum. Manufacturers advise cutting the cotton wool before unrolling the roll.

Are there any nuances in transportation and storage?

Manufacturers recommend storing mineral wool in an intact package, and it is better if the pack is on a flat surface. Each stack of packages should not be higher than 2 meters. The optimal storage conditions are closed spaces that are resistant to moisture ingress. It is not recommended to store the insulation on the street, but if this happens, then you need to cover it with a tarpaulin or film.

You need to store cotton wool only in a horizontal position.

When transporting, you should follow the same rules: transport cotton wool horizontally and in a dry truck body. You also need to provide the material with protection from mechanical stress and from atmospheric precipitation. When loading and unloading material, it must not be strongly compressed.

Unpacking mineral insulation also requires certain nuances. The material should be removed from the packaging only before starting work, which will minimize the various risks associated with damage to the insulation. When laying out material for cutting, use its packaging as a bedding. Thus, the product will not get dirty. Also, the packaging can be used to collect other waste at the construction site.

Material characteristics and properties

Before starting construction or repair work, the owner of the premises thinks about what criteria should be used to choose materials. Currently, the assortment of sale is replete with a variety of canvases that differ from each other in raw materials, price, scope, operating characteristics.

The term “mineral wool” means three types of materials, namely:

- basalt (stone);

- slag;

- glass wool.

Glass wool (fiberglass) has a low density and high hygroscopicity. The material does not have moisture resistance properties, and one should not expect heat resistance from it: when a high heating temperature (about 300 degrees) is reached, the wool fibers melt, and the material no longer performs the function of insulation. Glass wool on sale in rolls.

Glass wool is produced by blowing: an industrial centrifuge creates streams of air that go directly into the raw material. Due to the flow of air, fibers appear from the threads, moreover, they can have different lengths, directions and thicknesses.

Mineral wool has low thermal conductivity, allows steam to pass through due to the cells in the structure, and almost does not absorb water. In addition to the base, there are few binding elements in the composition, which allows it to withstand high temperatures. The material is widely used as sound insulation and insulation for various substrates and surfaces. Produced with canvases that vary in strength.

Slag wool for room insulation

Slag wool is the cheapest option for insulation. The material consists of fibers that are wastes from blast furnaces, it is not dense and does not have good heat resistance. If slag wool is overheated, it will sinter. Therefore, the material is not suitable for insulating premises adjacent to heat sources, and is also not recommended for the construction of houses.

The structure of a horizontal layer of any kind of mineral wool is created in the direction of the grain. The formation of vertical sections occurs due to elements that are located chaotically. Each type of material has its own characteristics and external differences.

Cutting mineral wool, how and how to cut mineral wool in rolls and slabs

A distinctive feature of mineral insulation is the structure consisting of fibers, which must be solid to ensure thermal insulation. In this regard, special attention should be paid to the cutting process. Do not use cardboard or fabric scissors or ordinary table knives to cut the material. These tools are not intended for such a material, since they can spoil its appearance and impair its useful properties. It is very useful for novice repairmen and builders to find out what tools are suitable for this business.

What are the remnants of mineral wool useful for?

The remnants of the insulation do not need to be thrown away: they will also come in handy for the pantry or utility room. Many people strive for budgetary insulation, therefore, they use scraps and leftovers of material.

Waste rock wool can be recycled for later use. In this case, special machines are used.

In order for the process of warming the room to go properly, you should know what to cut the mineral wool and how to do it. If you follow the simple rules for working with this insulation, then you can achieve a good result.

Recommendations on how to work with insulation

Insulation of the attic space is an effective way to reduce body losses as a result, the house needs to be heated less, which means that you can save on electricity. Mineral wool insulation is a versatile high performance option for thermal and acoustic performance as well as fire resistance.

What rules need to be followed:

- work in a well-ventilated area.

- use personal protective equipment for work: mask, goggles, respirator.

- work in overalls: well-buttoned overalls, headwear, construction gloves.

- after work, hands and face are thoroughly washed under cold water. Overalls are shaken out of dust.

Cross cut material

For cross-cutting, the rock wool roll is unpacked. Make markings on both sides. Then a flat bar is applied: a ruler, a piece of profile or a bar.

Important. When the insulation is cut, they put a board so that the knife does not blunt.

Longitudinal cut of material

Mineral wool in rolls is cut unpacked. The roll is placed on a hard, flat surface. The required length is measured with a tape measure. Labels are placed in three places around the packaging circle. The place of the cut, for accuracy, is wrapped with molar tape.

Then they take a saw and cut a roll of mineral wool in a circle. After the cut piece is separated, remove the packing film.

Important. Masking tape is wound on a roll from the opposite side of the workpiece so that after cutting the remaining part of the roll does not unwind.

Are there any nuances in transportation and storage?

Manufacturers recommend storing mineral wool in an intact package, and it is better if the pack is on a flat surface. Each stack of packages should not be higher than 2 meters. The optimal storage conditions are closed spaces that are resistant to moisture ingress. It is not recommended to store the insulation on the street, but if this happens, then you need to cover it with a tarpaulin or film.

You need to store cotton wool only in a horizontal position.

When transporting, you should follow the same rules: transport cotton wool horizontally and in a dry truck body. You also need to provide the material with protection from mechanical stress and from atmospheric precipitation. When loading and unloading material, it must not be strongly compressed.

Unpacking mineral insulation also requires certain nuances. The material should be removed from the packaging only before starting work, which will minimize the various risks associated with damage to the insulation. When laying out material for cutting, use its packaging as a bedding. Thus, the product will not get dirty. Also, the packaging can be used to collect other waste at the construction site.

Storage and transportation of mineral wool is carried out in even stacks so as not to damage the material

Since the material is porous, brittle and hygroscopic, it must be handled appropriately.

When transporting and storing mineral wool, it is recommended to observe the following rules:

- In the process of loading and unloading, do not throw packages, but stack them neatly, avoiding them falling and strong squeezing.

- Transport bales in covered trucks, laying them horizontally on a flat bottom. Fix the insulation so that it does not hit the body walls.

- Store products in dry, closed rooms. If this is not possible and it is stored outside, cover with a film or tarpaulin to protect it from precipitation.

- Remove the slabs from the stack just before laying them. This will prevent moisture absorption and reduce the risk of accidental damage to the material.

Features of the installation of mineral wool insulation

Before installing mineral wool, you must do the following:

- check the rafter structure. If rotten elements are present, then they must be replaced;

- treat the roof with antiseptics;

- check communication systems: water supply and electricity;

- the pitched roof is best insulated with material in the form of slabs or rolls, since they fit well on the crate.

There must be a ventilation space between the mineral wool layer and the roofing material. When insulating a pitched roof in a private house, not only thermal insulation is provided, but also noise insulation.

Inexperienced specialists often make the following mistakes:

- do not use a heat insulator whose width is less than the distance between the rafter legs. In this case, heat loss will occur through the slots;

- do not insulate the roof with material with a high level of moisture. This will cause rotting of the wooden elements of the rafter frame;

- if you do not install a hydro and vapor barrier, then the thermal insulation system will not work properly, moreover, its service life will be significantly reduced.

How to cut mineral wool

The structure of mineral wool is fibers, and accordingly, when it is cut into the air, small particles of these fibers get into the air. To prevent them from getting into the respiratory tract and on the skin, it is important to create a safe working environment:

- provide good ventilation in the work area;

- use overalls and protective equipment. overalls, gloves, mask or respirator, goggles;

- immediately after finishing work, wash your hands thoroughly with cold water and then your face.

To minimize the amount of harmful dust in the air, cutting mineral wool should be done with tools with a well-sharpened, sharp working edge. Better to cut across the grain.

To obtain strips of the same width, the mineral insulation produced in rolls is recommended to first be cut directly in the roll without unrolling, and the mineral wool slabs are cut one by one.

To ensure even and accurate cuts, you must first mark the material or cut directly with a ruler.

For example: MORA knife for cutting mineral wool

The Swedish company MORA produces tools for cutting mineral insulation. A knife with a stainless steel blade is used for cutting stone and glass mineral wool. The blade is made of special cold rolled stainless steel and has a serrated edge. The ergonomic and comfortable plastic handle is suitable for use with gloves. Its characteristics:

- total length. 500 mm;

- blade length. 335 mm;

- blade thickness. 1 mm;

- weight. 0.238 kg.

A knife with a carbon steel blade is used for cutting various types of mineral insulation. Has a smooth, made of high quality carbon steel blade with a length of 350 mm. Plastic handle provides a good grip when wearing work gloves.

Cutting tools

In the production process, in order to cut the material into fragments of the desired configuration, special stationary equipment is used.

At home, you can use the following tools:

- Stationery knife. Simple and inexpensive attachment with replaceable blades that are easy to change as they wear out. Thin steel fits well into the material based on basalt and glass, but is practically powerless over slag slabs. The downside is that such a product can only cut mineral wool up to 50 mm thick.

- Hacksaw for metal. An excellent solution if you need to cut slag or stone wool up to 100 mm thick. On sale there are single-sided and double-sided blades with small and large teeth. You can easily choose the most convenient option.

- Special knives. Products have narrow blades up to 34 cm long with prongs without setting. The handles are specially adapted for cutting at an optimal angle. Different models have blades made of cold-rolled stainless steel or carbon steel.

- loaf knife. The device is a good analogue of a special tool. For work, you need to choose knives with serrated rather than wavy edges. Blade length must be more than 15cm.

- Cutting machine. The equipment is quite expensive, but productive. Allows for precise and even cuts. It makes sense to purchase a machine if there is a large amount of insulation work to be done.

The choice of a device for cutting mineral wool is determined by your own priorities, building skills and financial capabilities.

How to cut mineral wool

The main technical condition of the process is the preservation of the structure of the material. the fibers must remain intact and maintain their position in space. To keep the line of the mowing line accurate and even, you should first apply the markings with a marker using a tailor’s meter or rule. Slabs should be cut by placing them on a table so that the cutting line is suspended. After this, you should, avoiding excessive pressure, make translational movements with the tool.

You need to finish cutting by holding the cut fragment in weight so that it does not come off under its own weight.

How to cut mineral wool insulation

Mineral wool is a popular and effective thermal insulation used for interior and exterior work in the arrangement of residential and commercial buildings. A feature of the material is its unique spatial structure, which ensures high performance. Violation of the order of the fibers leads to an increase in the thermal conductivity of the product, which requires the choice of a special technology for cutting slabs.

- Characteristics and properties of mineral wool

- Correct material handling

- Cutting tools

- How to cut mineral wool

- Safe working conditions

- Remains of mineral wool

Characteristics and properties of mineral wool

You need to cut the insulation with the tools that are best suited to its type and technical characteristics.

For thermal insulation work, the following types of mineral wool are used:

- Stone. Consists of integrated dolomite rock fibers. Basalt is mainly used for manufacturing, which is characterized by high strength. The material is used as insulation and for the manufacture of acoustic panels. Cutting stone wool is easy as it is soft and pliable.

- Slag. Manufactured from waste from the steel industry. It is used more in the decoration of utility rooms, as it contains impurities of toxic materials, has a pungent unpleasant odor. Cutting mineral wool in slabs is difficult, since it is fragile and unstable to pressure.

- Glass. The raw materials for production are cullet, lime and stone chips. Consists of many interwoven glass fibers that break easily. Supplied on sale in tightly rolled rolls. Cutting glass wool is easy as the material lends itself to any sharp tool.

The ease of installation and the quality of the final result depend on the quality of cutting the insulation.

Safe working conditions

The main component of mineral wool is thin and sharp fibers. In the process of work, they come off the base and rise into the air. The contact of these particles on the body causes burning of the skin, pain in the eyes and irritation of the respiratory mucosa.

In order to prevent harm to your own health, you must create the following working conditions:

- elimination of accidental entry to the place of work of strangers;

- removal of people and animals to a safe place if cutting is done outdoors;

- use of overalls, mask, respirator, sealed glasses and rubberized gloves;

- high-quality ventilation in the room, excluding the ingress of volatile substances into neighboring rooms;

- cutting across the grain to reduce the amount of volatile compounds;

- wet cleaning with preliminary cleaning of surfaces with a vacuum cleaner;

- covering the insulation with plaster, vapor-permeable or windproof film for the purpose of complete isolation.

After the end of cutting and installation, you need to take a shower, preferably under cool water, so that the fibers more easily lag behind the skin and hair.

Correct material handling

Since the material is porous, brittle and hygroscopic, it must be handled appropriately.

When transporting and storing mineral wool, it is recommended to observe the following rules:

- In the process of loading and unloading, do not throw packages, but stack them neatly, avoiding them falling and strong squeezing.

- Transport bales in covered trucks, laying them horizontally on a flat bottom. Fix the insulation so that it does not hit the body walls.

- Store products in dry, closed rooms. If this is not possible and it is stored outdoors, cover with a film or tarpaulin to protect it from precipitation.

- Remove the slabs from the stack just before laying them. This will prevent moisture absorption and reduce the risk of accidental damage to the material.

The technology of insulation involves the installation of plates with spikes, with a compression of 1-2 cm on each side. Based on this, you need to cut the mineral wool with an error in size of no more than 0.5 cm.

Remains of mineral wool

After the thermal insulation is carried out, a certain amount of unused material remains. Given its unique characteristics, there is no need to rush to get rid of slab scraps. They can be used profitably in the household. If this is not planned to be done immediately, the insulation must be hermetically packed and removed to a place inaccessible to children and animals.

It is advisable to use mineral wool to insulate such structures:

- doghouse;

- barn for pets;

- blind area around the house;

- garage walls and ceiling;

- home workshop;

- basement;

- food cellar.

You can benefit from the remnants of mineral wool by handing it over to a collection point for recyclable materials. The accepted material is sold to enterprises that make granules from it, which are used for re-production of insulation.