How to cut tiles for pipes

Large hole

If you need to get a round (and not only) hole of a large diameter, for which you do not have a ballerina / crown, then you can use the following technique.

- Mark the center and draw a circle with the diameter you need. This can be done with a compass or a thread with a pencil glued to the center.

- Using a small diameter tile (or carbide tipped concrete) drill bit, drill holes along the line inside the circle. Try to make them as close to each other as possible.

We drill the maximum number of holes in diameter along the marking

To prevent the drill from slipping on the glaze, stick some masking tape on it. It is also convenient when working together. you can easily make notes on paper that will be seen perfectly.

Planning Before Drilling Tiles

Before making holes in the tile, determine which tool will be used during the work. It should be borne in mind that an angle grinder can cut through ceramics that are not laid on the walls, while a perforator with various nozzles can make holes not only in the tile, but also drill the walls under the pipes with it after laying.

Method 3. drilling holes with diamond core bits

This method is used when it is necessary to obtain cavities for sockets, outlet of taps for installing a bathroom mixer, etc.

Drilling is performed by rotating the crown on the pilot drill. And the quality and accuracy of the hole will depend on the quality of the diamond dusting and the size of the grain. The main disadvantage of this method is the high cost of the crown itself, which ranges from 30 to 80.

The essence of this method is as follows: a movable cutter, fixed on a rod, rotates with a power tool together with a pilot drill. Due to the mobility of the cutter and the ability to move it along the rod, the tool can be adjusted to any desired hole diameter within the rod length. This is very convenient and allows you not to buy, for example, a large assortment of crowns of different diameters.

Another significant advantage of using this tool is its price, which is low and ranges from 10 to 15.

I carry out the drilling process in several stages:

- I mark the center of the circle;

- I adjust the circular drill to the required diameter;

- I cut through the glazed layer;

I make a groove on the back of the tile;

I cut a hole from the front side.

Along with many advantages, this method also has disadvantages:

Firstly, this tool is not designed to produce a very large number of cuts. The service life of such a drill is 30-40 holes, although this is quite enough for home use.

Secondly, the tool must be used very carefully and use low speed when cutting. If these conditions are not met, there is a high probability of small tile chips at the cut.

Glass cutter

The glass cutter is suitable for cutting wall tiles, it is quite difficult for them to cut hard floor porcelain stoneware, the work with a roller glass cutter is performed in the following sequence:

- The product is laid on a flat hard surface and the line is drawn along the ruler with slight pressure towards you.

- Break the tile against a sharp hard angle along the mowing line.

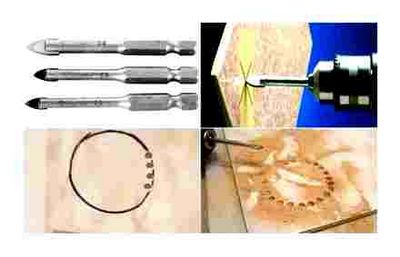

Drilling with a ceramic drill

Typically, the walls in the kitchen or bathroom are laid out with glazed ceramics, which have a soft base and a top layer of durable and smooth glaze (tiles). For its drilling, special pen drills with a flat spade-shaped tip with sharpened edges have been developed, which are practically useless when using any of them in work with harder tile materials (porcelain stoneware).

The main problem when using drills is the removal of the top layer of glaze on which the tip slides. For this, masking tape is glued onto the glazed surface (several layers can be glued) and a point for the future hole is marked. With the help of a plate drill, you can make a cut of a large radius by making a number of holes around its perimeter, although the point will quickly fail.

Ballerina use

You can make a hole with a ballerina in 5 steps:

- Circle center mark.

- Drilling diameter setting.

- Cutting through the glaze.

Cut through the first few millimeters of the glaze on the front side

The ballerina is enough for about 20-30 holes, which will be enough for home use. When working with it, you need to observe safety precautions and do drilling at low speeds, hold the drill strictly perpendicular to the tile.

Method 1. drilling with a ceramic tile drill

Difficulty when drilling glazed tiles is a very durable top coating. glaze. And in addition, this layer is very slippery, so an ordinary HSS drill will not work. it will quickly become dull.

How to Cut Tiles around Pipes and Drill Holes in Bathrooms & Toilets. Tile Mountains

For small-diameter tiles, it is best to use special tile drills.

The main feature of this drill is the shape of its cutting part, equipped with a carbide insert with a pointed end, which makes it possible to start the drilling process at a set point more accurately. Similar drills are used to drill glass. even more slippery material.

For a more accurate hit in the desired marked place during drilling, it is recommended to mark the drilling site and glue a piece of adhesive tape to this place. Or stick a piece of masking tape and mark the drilling site on it.

And one, and the other method makes it possible to start the process of drilling a hole in the tile at a specified location without deviation. The drill will not slip and move away from the mark when rotating. As the work is completed, the tape or masking tape is removed.

How and how to cut a hole in a tile for an outlet or pipe: options, tips

When arranging bathrooms and toilets, the walls and floors of which, as a rule, are finished with tiles, you cannot do without such procedures as installing pipes and installing electrical outlets. To carry out these activities and obtain a high-quality result, it is important to know how to cut a hole in a tile, which tools and equipment to use for this.

A hole in a tile can be made using a special tool or using improvised means.

Cut tiles with a roller tile cutter

The easiest and most reliable way. Any roller (machine tool) tile cutter has:

A ruler that allows you to cut off up to 6-8 cm without additional marking. Also, the kit includes a retractable ruler (not shown in photo 1) and the right angle during cutting is, as it were, maintained:

Photo 1. Setting the tiles in the tile cutter.

Elastic tile pads glued to the metal body to prevent slipping of the tile to be cut and allow the pieces of the tile to land softly.

A tab that allows you to split the cut tile along the cut mowing line.

And the most important thing. a large lever (special thanks to Archimedes, because such a tile cutter is often called mechanical) and a comfortable handle (almost invisible in photo 2) for cutting and breaking the cut tiles:

Photo 2. Splitting a tile cut with a tile cutter.

As a result, cutting the tile takes a few seconds. It is enough to set the tile, once with force hold the chisel, and then, slightly shifting the stops (light yellow in photo 2), press the lever. Everything and business, dust and noise. minimum.

The essence of this amazing process is quite simple: by cutting through the glaze layer on the tile, even slightly, we not only reduce the thickness of the tile (usually tenths of a millimeter), but also create an area of critical internal stresses. In particular the slit. it is the result of not only fracture but also plastic deformation. When we press down on the lever, the force is transmitted through the stops to the right and left sides of the tile lying on the ledge. Such a tile is like a beam on one support. a ledge on which two forces act. the edges of the stops. In this case, tensile stresses arise in the upper zone of the tile (since the bending moment on the support is maximum), and even shear stresses. Accordingly, the longer the stops, the easier it is to break the tile (the same lever rule applies here). And if the stops are wide enough, then the load transfer to the tile will be more even. Theoretically, if the stops are equal in width and length to the parts of the tile to be cut, then the tile may not be cut at all, but immediately broken. However, in practice, tiles are required in different sizes, and even transfer of the load to the cut tiles is not at all necessary if the cut is made well. Therefore, the dimensions of the stops are usually not very large.

You can put the tile cutter during work on any more or less flat surface, you can also cut right on the floor.

However, the roller tile cutter also has disadvantages:

Cutter guides. as a rule, pipes that are quite easily deformed, respectively, the cutter does not always follow the intended mowing line. In addition, when cutting, the tile rests on the ledge and on the edge of one of the elastic pads, so the angle between the cutter and the tile surface is not 90 °. If a deviation of 1-2 mm from the intended size does not bother you much, then you can ignore this drawback. However, if you make additional spacers of such a height that the tile rests on them more than on the ledge during cutting, then this problem can be partially solved. And cutting with additional spacers is much more convenient. But before splitting the tiles, the additional gaskets need to be removed by themselves.

When working in a dusty room (and where ceramic tiles are laid, as a rule, it is always dusty), the guides become clogged with dust and the cutter does not slide on them as well as a new one. Therefore, the guides periodically have to be wiped and sometimes lubricated.

The metal stops of the lever must also have an elastic sheath so that splitting does not damage the face of the tile. However, such elastic shells are not always included in the tile cutter kit, and sometimes they can simply get lost. In such cases, I simply paste over the surface of the stops with masking tape.

Since the load during breaking is transmitted unevenly, it is not always possible to break off a strip with a width of more than 1.5-2 cm, especially if the tile is long enough.

Floor tiles are usually thicker and stronger than wall tiles, so you need to use a lot of force to cut them. At the same time, the roller on which the roller cutter is put on wears out quite quickly (if the tile cutter is cheap), and the guides become loose faster. Well, for porcelain stoneware, a roller tile cutter is generally not suitable.

Large dimensions of the machine tool tile cutter. The larger the tile cutter, the easier and more convenient it is to work with it. However, buying a large tile cutter for one renovation in an apartment, and then keeping it forever on the balcony or in the garage. not very nice.

Relatively high price. A mechanical tile cutter costs from 10 to 70, depending on the size, manufacturer and the availability of additional devices, for example, a rotary ruler that allows you to cut tiles at different angles, a compass for cutting holes.

Splitting

Since ceramic tiles are similar in their properties to glass, you can cut the tiles with an ordinary glass cutter, and then break off the necessary or unnecessary part of the tile, as when working with glass. Once upon a time (back in Soviet times) I did just that, sometimes I cut my hands in blood, trying to break off a rather narrow strip of tiles. However, there are now more convenient tile cutting tools. Now you can always:

How to cut tile

In fact, there are only two ways to cut tile (at least known to me): splitting and sawing. And each of these methods has its own advantages and disadvantages. Of course, when it comes to cutting round holes in a tile for a pipe or a socket, neither a simple tile cutter nor an angle grinder will help much, but then we will talk about more or less straight-line cutting of tiles.

Cut a tile with a machine electric tile cutter

These cutters will cope with any tile and allow you to get an almost perfect cut. However, machine-tool electric tile cutters are quite expensive: from 300 to 700. Accordingly, it makes no sense to buy such a tile cutter for one repair in an apartment.

Cut the tiles with a mini tile cutter

Miniature tile cutters or, as they are also called: “tile tongs”, in comparison with a machine tile cutter, consist of solid disadvantages:

No ruler. Therefore, for marking, you must have a tape measure or a metal ruler.

There is no guide. A carpenter’s corner or a metal ruler can serve as a guide, however, metal products can also slide along the surface of the tile and the cut can also turn out not along the mark.

The overhang for breaking tiles is very short, and the stops are not so long.

The length of the lever is also less, which means that more effort must be applied to break the tiles.

Since the load on the tile during breaking is transmitted almost in the form of concentrated forces, then chop off a strip with a width of less than 3-4 cm with a mini-tile cutter.Problem.

Nevertheless, the main advantage of the miniature tile cutter. its small size and weight. Also, the price of a mini-tile cutter is less: from 3 to 15.

Sawing

When it is necessary to cut a thin strip of tiles, and indeed when working with porcelain stoneware, electric tile cutters with diamond dust on the cutting part are usually used.

Cut off tile angle grinder

If you put a diamond wheel on an angle grinder, you get an electric tile cutter without a machine, i.e. without a ruler, without fixing tiles, without a guide. Therefore, the cut of an angle grinder is not as smooth (everything depends on skill) as in a machine tile cutter, but this is not always required. But the price of a simple angle grinder, coupled with a diamond wheel, rarely exceeds 25-40, and it is much easier to transport it from object to object than a heavy machine, and therefore even professional tilers often use the angle grinder.

How you can cut a sufficiently narrow strip of tile with an angle grinder is shown in the following

If necessary, the end of the tile in the place of the break is carefully sanded with the same angle grinder. Of course, you can cut through the tile with an angle grinder completely, but at the same time there is a high probability of damage to the glaze, because the cut piece, if it is very narrow, and the support under it is not reliable enough, can bend during cutting. So cutting through to the end only makes sense if the tiles are large enough.

Electric tile cutters have other disadvantages. it is a lot of dust and noise during operation, as well as the presence of electricity. Accordingly, when working with electric cutters, it is necessary to use personal protective equipment, such as a respirator, gloves, safety glasses.

And you also have a unique opportunity to help the author financially. After successfully completing the transfer, a thank you page with an email address will open. If you would like to ask a question, please use this address. Thank. If the page did not open, then most likely you made a transfer from another Yandex wallet, but in any case, you do not need to worry. The main thing is to indicate your e-mail exactly when making a transfer and I will definitely contact you. Plus, you can always add your comment. details in the article “Make an appointment with the doctor”

For terminals, Yandex Wallet number is 410012390761783

For Ukraine. hryvnia card number (Privatbank) 5168 7422 0121 5641

Webmoney wallet: R158114101090

Or: Z166164591614

Note: Perhaps your question, especially if it concerns structural analysis, will not appear in the general list or will remain unanswered, even if you ask it 20 times in a row. Why, is explained in sufficient detail in the article “Make an appointment with the doctor” (link in the header of the site).

Home cutting methods

Professionals prefer waterjet and laser cutting, which are performed on special machines. Their advantage lies in the fact that practically no significant mechanical and thermal effect is exerted on the surface of the material being processed. Cutting with a water jet mixed with abrasive or a laser beam controlled by a modern computer is used mainly in metal work, but they are second to none when cutting particularly durable floor tiles. These machines allow perfect cutting of a wide variety of shapes.

At home, it is also quite possible to perform curvilinear and curved cuts (for example, with rounded corners, diagonally or at 45). In this case, it is best to use a power tool or a jigsaw with a diamond thread. With their help, you can perform a fairly delicate work even on such an extra strong material as porcelain stoneware.

Regular thin glossy wall tiles can be cut with a roller glass cutter. But if there are a lot of such tiles, it is better to purchase a special tile cutter. Also, in the absence of power tools, you can try to cut the cuts of ceramic or mosaic tiles with nippers, and then grind them thoroughly. The main thing is not to “bite off” the notches in very large pieces.

It is easiest to cut gypsum tiles “under the stone”, since the gypsum polymer material from which it is made is quite plastic. Plaster tiles can be cut even with an ordinary wood saw, but a fine-toothed hacksaw is best for cutting such tiles.

Preparation for work

Ceramic, tiled, porcelain stoneware and gypsum tiles are quite a convenient material for decorating walls in a living room. But before you start laying it directly, you need to learn how to properly cut tiles at home. After all, the smoother the tiles are cut, the better the final result will be. Rarely is it possible to choose the size of a tile so successfully that it does not have to be cut. When facing, for example, an apron in the kitchen, it is unlikely that it will be possible to lay only solid plates of tiles, especially on corners, projections, pipe exit points and sockets.

- mismatch of shades

- irregularities of the front glazed coating

- mismatch in the length, width or corners of the tiles

- chips and cracks during transportation

Of course, taking into account the above, the material must be bought with a margin, usually an extra 10% is enough. By the way, it will be possible to practice on the rejected material and “get your hands on” if cutting tiles is not yet a well-developed skill for you.

After sorting, the tiles must be soaked in water for a period of one to three hours (the more modern the cutting tool, the less time it takes to soak).

During this time, you should prepare:

- table, stool or cutting board

- pencil, marker or felt-tip pen (for marking)

- a long ruler or measuring tape

- elbow, ideally metal

- respirator

- glasses

- earplugs / headphones (for machine operation or angle grinder)

How to cut a hole?

When cutting holes (for example, for pipes), an ordinary drill can come to the rescue. The highest quality and even holes are obtained using a nozzle in the form of diamond crowns, but the high price for such products does not allow them to be purchased for performing small-scale work.

How to Cut a Round Hole in Tile for Pipes and Shower Heads

How to cut tiles?

- Preparation for work

- What to cut?

- Home cutting methods

- How to cut a hole?

- Good advice

What to cut?

First, let’s list the most common and available tools for cutting tiles:

- roller glass cutter

- wire cutters

- hacksaw

- electric jigsaw

- manual tile cutter

- mechanical tile cutter

- electric tile cutter

- a circular saw

- Angle Grinder

If you need to cut just a few tiles for personal use, then the simplest tools that are available in almost every home are enough. But if you want to make money on laying tiles and, accordingly, cutting it, you will need to purchase the appropriate professional power tools.

The roller glass cutter is a wooden handle with a small diamond rotating wheel at the end. Cutting tiles with a glass cutter is the most famous, albeit not very simple, method. It is used for small volumes of work and on not too thick and durable tiles. To cut a tile with a glass cutter, you need to use a ruler and press the roller from edge to edge along the previously marked mowing line. At the same time, it is impossible to tear off the tool from the surface of the tile, it is also not recommended to re-carry it with a glass cutter along the already cut mowing line.

The glass cutter will not cut the tile completely, but will only scratch the strip. Next, you need to carefully, without haste, break the tile, placing it with the resulting cutting line on the edge of the table or board, lightly knock on it with the handle of the glass cutter and press the hanging edge. As a result, the material should crack exactly along the intended mowing line. After separating the parts, the roughness can be sanded with emery paper or a file.

Nippers are usually used to break off pieces of tiles. They are used if it is necessary to cut tiles for holes in various places: for pipes, frames, window sills, sockets, etc. The pliers do not cut in the literal sense of the word, but break off small pieces from the tile along the cut line. The pliers themselves have in their design two clamps coated with carbide. the upper one cuts the shiny glazed layer on the tile, and the lower one serves as a support. They work with nippers as follows: a cutout contour is applied to the tile, clamp the tile with nippers, clamp both halves of the tool and break off the tile along the markings. The resulting cut is cleaned with a file, if necessary.

You can also cut the tiles with a hacksaw. It is better to purchase a special hacksaw for ceramics, outwardly it almost does not differ from other types of hacksaws, for example, for metal or wood, with the only exception that its blade is coated with a special spraying of tungsten carbide. The main advantage of using a hacksaw is that the cut edges come out even, without chipping, chipping or roughness, and therefore almost do not require additional grinding.

The jigsaw is a fairly versatile and functional tool. You just need to purchase a special abrasive file (the so-called “rope”) for working with tiles. With its help, the tiles are cut evenly and accurately, and it also allows you to make holes and curly cutouts in the product. To cut the tile, you must first fix it, then turn on the jigsaw at medium speed and make a through cut along the previously outlined contour.

The manual tile cutter resembles pliers in appearance, with the only difference that one tip has a protrusion, and the other has a characteristic cut. In addition, a roller diamond cutter is placed at the edge of the tool. Using such a tile cutter is quite simple. First you need to cut through the glazed side of the tile with a roller. Then, holding the tile with pliers, break the segment exactly along the mowing line. It is important to ensure that the protrusion falls on the front glazed side, and the neckline on the back matte.

A mechanical tile cutter is similar in principle to a large glass cutter with additionally attached rails and a lever. When using a mechanical cutter, the tiles are placed on a support under the guides, and the lever is pulled to the nearest position. The tile should then be aligned with the mowing line and the cutter roller should be positioned on the edge of the marked mowing line. Then you need to gently move the cutter roller with the lever forward along the mowing line, pressing lightly on it in the process. At the end of the operation, the tiles are split by themselves exactly along the cut mowing line. However, the minus of such a tile cutter is that they will not be able to cut a piece less than 5 mm.

An electric tile cutter at home is rarely used, it is mainly in demand where tiles have to be cut on an industrial scale. The tile is cut with this tool using a rotating diamond-coated disk, which is permanently moistened with water from a special container. The material should be fed to the disc carefully, otherwise the tiles may crack.

The main advantages of such an electric tile-cutting machine are the absence of dust during operation, as well as the perfectly smooth shape of the cut, without chips and cracks. Significant disadvantages are that this instrument emits a rather loud roar during operation, rotates very quickly, and also throws sparks around itself. Therefore, when working with it, special precautions must be taken.

A circular saw is also rarely used at home, as it requires a separate workshop to work with it. Such a tool is a complete machine equipped with a toothed disc. A special dry cutting diamond blade is required to cut tiles. In the process of cutting, the prepared tile is pressed against the table and carefully pushed forward along the intended mowing line.

But almost in any household there is an angle grinder. Using this tool, you can also cut tiles, you just need to take care of purchasing a diamond cutting disc and install it in the direction of movement of the tool. For cutting it is necessary to first mark the tile, and then carefully make a cut in it, smoothly advancing the tool at medium speed “away from you”. The disadvantage of working with an angle grinder is a large amount of dust and sparks, therefore, all possible safety measures must be observed when working. In addition, small chips may form around the edges of the tiles after cutting with the angle grinder, which will need to be sanded.

Good advice

To achieve an ideal result, just a good tool is not enough; it is important to know a number of nuances that professionals in their field can familiarize with. Here are some tips on how to cut tiles quickly, efficiently and with minimal losses.

With manual methods of cutting tiles, it is recommended to additionally use the so-called miter box. a rectangular box with special slots (straight and at an angle of 45 degrees) on the sides for a more accurate and even cut.

If you don’t have a sturdy line guide at hand, another flat-edged tile can replace it.

The tiles should be cut with well-defined, precise movements. And to avoid splitting the tile while breaking off the cut piece, you can duplicate the shallow line of the cut from the seamy side of the tile. This can be done with any cutting tool at hand.

When cutting a particularly durable tile (for example, porcelain stoneware), an angle grinder, experts recommend, by making an incision, place a stop under the tile (for example, a nail or a thin metal twig), and only then, by pressing on both parts, break it.

Carrying out figured cutting with a grinder, you do not need to try to immediately process large pieces of tile. It is better to break off the part with pliers for a start, and then trim it with a file and sandpaper.

You can see the methods for cutting tiles in the following videos.

Drilling holes with a carbide drill bit in concrete

Concrete bit drills are widely used to create small holes in laid tiles, the household drill used should be speed-adjustable. When working on tiles, several rules should be observed:

- It is better to drill at low speeds.

- To avoid splitting the surface of the tile, the holes are drilled very carefully without the perforation mode.

- It is also necessary to exert minimal pressure on an electric drill or hammer drill, which increases as it passes through the tile layer.

Calibrator for metal-plastic pipes. purpose and instructions for use. Perhaps reading about how to make a hole in a tile for a pipe, it will also be interesting to learn about the existing types of calibrators used for the installation of metal-plastic pipes, technology and instructions for working with them.

Tool for cutting tiles in a straight line

When carrying out tiling work, ceramics are cut in a straight line using the following special tool.

Planning Before Drilling Tiles

Before making holes in the tile, determine which tool will be used during the work. It should be borne in mind that an angle grinder can cut through ceramics that are not laid on the walls, while a perforator with various nozzles can make holes not only in the tile, but also drill the walls under the pipes with it after laying.

Drilling with a ceramic drill

Typically, the walls in the kitchen or bathroom are laid out with glazed ceramics, which have a soft base and a top layer of durable and smooth glaze (tiles). For its drilling, special pen drills with a flat spade-shaped tip with sharpened edges have been developed, which are practically useless when using any of them in work with harder tile materials (porcelain stoneware).

The main problem when using drills is the removal of the top layer of glaze on which the tip slides. For this, masking tape is glued onto the glazed surface (several layers can be glued) and a point for the future hole is marked. With the help of a plate drill, you can make a cut of a large radius by making a number of holes around its perimeter, although the point will quickly fail.

How to drill a hole in large tiles. step-by-step guide

When carrying out repair work, it is often necessary to obtain holes with a large diameter of 100 mm. for installing sewer outlets or floor drains. It is difficult to find crowns and ballerinas of a similar size for household purposes on sale, it takes a long time to do the work with drills, so the best method is to use an angle grinder. Ceramic cutting is carried out as follows:

How to Cut Tiles Around Pipes

- First of all, to reduce dust and facilitate cutting, the tiles are immersed in water for a while. It should be borne in mind that all adhesives are designed for gluing dry tiles, therefore, after cutting the hole, it will take some time for it to dry. To speed up the work, many tilers do not wet the ceramics, gluing it immediately after cutting the fragment.

- On the inside with a marker or pencil, mark the outline of the cut area. Many tilers do this from the glazed side, which further leads to churning of the glaze and getting poor quality edges.

- Cut out a round fragment from the inside. The large diameter of the hole allows you to do this immediately along the contour without preliminary cross-cuts in the center and cutting out squares. At the same time, the angle grinder is held at an angle with an inclination to the center of the circle, at first a small depression is made, which is increased with each pass. The radius of the cut circle is made a few millimeters less than the desired size.

- After several passes of an angle grinder around the circumference, it is necessary to determine the moment when the wheel can be easily knocked out, for reliability, you can leave solid slots in some places.

- Since the circle was cut from the inside, its edges inside will be very thinned. this will make it easy to give it the correct geometric shape with pliers or pliers.

Glass cutter

The glass cutter is suitable for cutting wall tiles, it is quite difficult for them to cut hard floor porcelain stoneware, the work with a roller glass cutter is performed in the following sequence:

- The product is laid on a flat hard surface and the line is drawn along the ruler with slight pressure towards you.

- Break the tile against a sharp hard angle along the mowing line.

Using a jigsaw

Another power tool that can be used to work with ceramics is the electric jigsaw. When working with it, use a special knife with diamond dusting, the slot is made as follows:

- A hole is drilled at the edge of the cut-out circle with such a size that a file from a jigsaw will enter into it.

- Perform a cut along the circumference or other required shape.