How to fit the burrs to the cultivator

.Preparing and installing the burrs.

The cutter kits for a single axle tractor are: 16, 24 or 32 cutting inserts. What kind of kit to choose. it depends entirely on the type of soil on the site, as well as the area of cultivated land. If you have a small area to cultivate. it is not recommended to use more than 16 cutting inserts. A set with 8 inserts on one side and 8 inserts on the other is considered optimal. If you decide to use sets of 24 or 32 plates for small plots it will increase load on the tractor engine and as a result will tire the operator a lot.

The stage of preparation of cutters consists in the correct assembly of sets of cutting plates. You must be absolutely sure that their cutting part is in the same direction.

The cutting parts of the tiller must never be sharpened. If you sharpen them, the weed roots will not rise to the surface of the cultivated soil. The root system is simply cut off by the sharpened burrs and stays in the ground. After a while the weeds regrow in the same place and cultivation is absolutely pointless.

It is also worth mentioning that sharpened cutters greatly increase the load on the engine of a power tiller.

Also the sharpening of the burrs has a negative effect on the depth you have set. If you sharpen the router bits, the single axle tractor will occasionally dig into the ground as it drives forward. This happens because the sharpened cutters do not grip the ground, but cut. This leads to the fact that they begin to burrow heavily into the ground to a depth of more than 30 centimeters.

So you have now finished assembling the router set. Now you can move on to the next stage of preparation of the power tiller. the installation of cutters on it. You must carefully see to it that the direction of the cutting part of the plates is placed in the direction of movement of the motoblock forward. It’s very important not to mix up left and right side cutters and put them in their places.

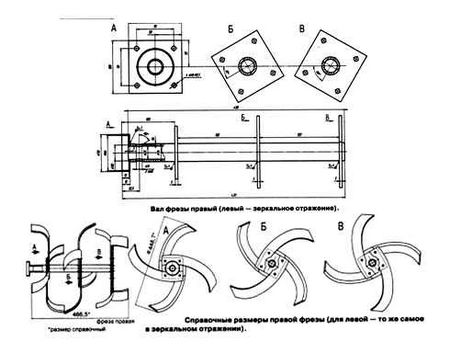

Cutter drawing for a power tiller

Is it necessary to sharpen tiller blades of a power tiller? Cutters for single axle tractor

Such equipment as a tiller is essential for any power tiller, as it can be used for most of the ground cultivation work. Generally, the tiller comes with the machine, but in cases where you need to change the width and depth of processing, you should buy the equipment separately.

Additional power tillers allow to increase a power tiller’s functionality and simplify its operation. Experts recommend having several pairs of cutters in your arsenal.

Which tillers are best for your power tiller??

Such “knives” for tillage can be conditionally divided into two large groups. Each of them has its own special characteristics and is suitable for a certain kind of work.

Sabre-shaped power tiller

The most popular and versatile models that are effective in various earthworks. These models use the optimal shape of the knives, for the manufacture of which the manufacturers choose high quality durable steel.

The models have a collapsible design, so their installation and maintenance is as simple as possible.

#springhowfitting #cultivator Cultivator spring fitting | Tractor | agriculture | farmer | land

Goose-feet

These models are relatively new on the market. With their help any virgin land can be processed, they are also effective in the cultivation of hard and difficult soil.

- solid construction, which provides high accuracy of work;

- The equipment is good at fighting weeds;

- ease of operation, the possibility of replacing parts at home.

These models, unlike sabre cutters, are made of carbon steel, which is not as strong.

Homemade tillers for the power tiller

Manufacturers offer different versions of tillers for power tillers. You can use one set of cutters or buy two different types of devices, changing them depending on the conditions for processing the soil.

Some craftsmen prefer to use homemade products, which, if properly assembled, will be no worse than the factory ones.

The main advantage of independent creation of a tiller is that it can be adjusted to the specific features of the plot.

How to assemble properly a tiller on a single-axle tractor?

The assembly of the tiller with your own hands should be done as correctly as possible. And here it is particularly important to make sure that the active part cuts into the ground during work. To do this, it is initially recommended to study the drawings, and then already proceed to the manufacture of equipment.

The following tools are required to create tillers:

- Rotor axis of the required length. It can be divided into two parts if you need to assemble a drill with two blocks.

- Short axle.

- Gearbox with clamps.

- Left and right knives.

- Bolts, washers, nuts.

The assembly does not take more than an hour, but it is important to install the blades in such a way that they do not interfere with the rotation.

- The long rotary axle is equipped with knives at an angle of 30 degrees.

- you must combine four blades on a single unit by attaching them to the gearboxes.

- Then the correctness of the construction is checked and all fasteners are tightened.

This design is very robust and can withstand quite high loads.

mounting the cutters on a single axle tractor

to mount the cutters on a single-axle tractor, you should use special wooden trestles, the height of which should be about 50 cm. the machine needs to be supported on the coulter and tilted at a 45 degree angle. then the wheels are removed and the cutters are put on. on the outer ends on both sides are installed special plates, which make the unit run more smoothly and steadily.

Is it necessary to sharpen cutters on a single axle tractor??

Any soil tillers are self-sharpening tools. Sharpening is not necessary for them, as it can only spoil the design. Only in some cases, if you have been using the tiller for a very long time and see that it has become poorly tilled, you can sharpen the blades.

A tiller. an important element of every machine. Homemade properly assembled tillers can be used on any modern power tillers, particularly on Neva MB 1 and MB 2, MTZ and others. Such designs will assist in tilling the land and make agricultural tasks easier.

Cutters (tillers) for power tillers and power tillers

Cutters for a power tiller. mounted equipment designed for plowing, loosening the soil, mixing it with mineral and organic fertilizers, fighting weeds and pests.

Due to the high agronomic characteristics and a large degree of crumbling, tillers create an optimal density of soil, increase its biological and biochemical activity, while significantly increasing yields. Land cultivation is performed in the spring period before planting crops and after the autumn harvesting of coarse-stemmed plants.

The devices are installed on power tillers and cultivators as a working tool. They can be supplied in a basic set when purchasing motor equipment, sold separately in domestic markets, and some craftsmen make them themselves.

How to work a power tiller properly. How to adjust a cultivator correctly?

In order to exclude the burying of the cultivator and a number of other common problems, the owner of the equipment should perform a number of actions on its preparation and adjustment.

- First, the cultivator must be installed on a thick board, and remove the factory wheels from it. Instead, mount a set of cutters on the left and right side of the machine. One set of cutters includes 8 cutting blades. this number of elements gives the best result in soil processing;

- When installing the cutters pay attention to the position of the blades. They must only point forward. The working tip of each share must not be pointy. Otherwise, the cultivator will not move forward, and will start to dig into the ground. In addition, the sharp cutters will cut the weed stems, rather than winding them up and pulling them out together with the roots;

- Next, you will need to install the necessary coulter bar on the machine;

- the coulter is in the form of a slat bar with holes in it. It is necessary for precise adjustment of the tiller position when cultivating the plot;

- To fix the coulter it must be fitted into the bracket and secured with cotter pins and bushings. A second hole is selected for this purpose. The tine is measured from the bottom of the coulter. This will set the working depth to 20 cm. This is sufficient for good tillage and the elimination of large weeds;

- To increase the depth of cultivation, the coulter should be lowered down, and attached to the earring through the upper hole of the element;

- To reduce the depth of plowing, the coulter should be lifted up, and fixed to the ear through its lower hole.