How to reduce revolutions on an angle grinder with your own hands

How to make POLISHER MACHINE from ELECTRIC DRILL and old ANGLE GRINDER

How to assemble a regulator with your own hands?

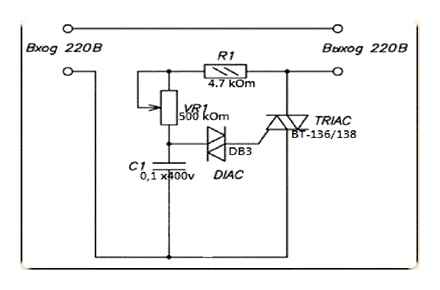

A simplified and rather reliable frequency converter for an angle grinder is constructed with your own hands from available electrical parts. Below is a diagram showing all the required components for mounting on a printed circuit board of the device of interest to us.

- symmetrical triode thyristor (or triac, triac) DIAC (DB3);

- resistor (resistance) R1 (its parameters should be 4.7 kOhm);

- additional triac VT136 / 138 (TRIAC);

- capacitor C1 (400 V, 0.1 μF);

- additional resistance VR1 for 500 kOhm.

A similar scheme operates according to the following method.

- The charging time of the capacitor is modified by an auxiliary resistor (it is called the trimmer). When voltage is applied to the circuit, the triacs are in the closed position, and a zero voltage value is observed at the output.

- In the process of charging the capacitor, an increase in voltage is noted on it, which leads to the opening of the DB3 triac. As a result, the voltage falls on VT136 / 138. This thyristor element also opens up, and an electric current flows through it.

- After that, the symmetrical components are closed again and remain in a similar status until the capacitor is completely recharged in the opposite direction.

- Ultimately, at the conclusion, we obtain a deterministic signal of finite energy, complex in configuration. Its exact range is determined by the period of performance of the functions of the circuit capacitor. auxiliary resistance. resistance R1.

Triacs are usually located on a printed circuit board. It is easy to create it from textolite (multilayer extruded plastic is used, consisting of heat-insulating fiber and foil). Individual craftsmen cut the board with a cutter. It is practiced to place the circuit elements using the hinged mounting method. Triystres are mounted only on an aluminum or copper heat exchanger. It plays the role of a good heat sink.

The test of the assembled device is carried out using an ordinary 40-60 W incandescent lamp. Connect it to the circuit and start to regulate the glow power. If the brightness changes, then you have done everything correctly. Now you can start installing the regulator in the shell of the angle grinder. This is not very easy to do, since it is necessary to ensure that the auxiliary device does not interfere with you when using the angle grinder.

You will need to calculate the installation location of the homemade control device yourself, in accordance with the design features of the angle grinder. The installation of the circuit is performed:

- in an additional box mounted on the unit body;

- into the handle of the holder;

- into a small empty niche (it is designed to cool and circulate air masses) in the rear area of the angle grinder.

The circuit itself is connected to the device by integrating it into the electric power supply channel of the angle grinder. With this, you, I suppose, will not have difficulties.

Testing the electronic unit

Before connecting the unit to the instrument, we will test it. Take an overhead socket. Mount two wires in it. Connect one of them to the board, and the other to the network cable. The cable has one more wire left. Connect it to the network board. It turns out that the regulator is connected in series to the load supply circuit. Connect a lamp to the circuit and check the operation of the device.

Angle Grinder Application

During start-up of an angle grinder (angle grinder), high dynamic loads appear on the tool parts.

Expensive models are equipped with a soft starter, but not ordinary varieties, for example, the Interskol angle grinder. An inertial jerk is capable of pulling an angle grinder out of your hands, and there is a threat to life and health. In addition, when the electric motor of the tool is started, an overcurrent occurs and, as a result, wear of the brushes and significant heating of the stator windings, the gearbox wears out and the cutting disc may be destroyed, which can crack at any time and cause harm to health, and maybe even life. The tool needs to be secured and for this you should make an angle grinder with speed control and a smooth start with your own hands.

For what purpose is the angle grinder low speed?

The integrated wheel speed control option enables the gentle handling of materials such as wood or plastic. At lower speeds, comfort and safety are increased. This option is most practical in radio and electrical installation, service stations and studios engaged in restoration.

In addition, among professionals who use power tools, there is a judgment that the more trivial the device is arranged, the more reliable it is. And it is advisable to take the additional service “stuffing” beyond the boundaries of the angle grinder. With this approach, equipment maintenance is greatly simplified. In this regard, some companies deliberately produce portable individual electrical controllers that are connected to the network cable.

Making a soft start

The circuit is assembled on a printed circuit board with dimensions of 45 x 35 mm, the board is laid out as compactly as possible so that it can be built into the body of a tool that requires a soft start. It is better to solder the power wires directly to the board, but if the load power is small, then you can install the terminal blocks, as I did. The board is made by the LUT method, photos of the process are presented below.

Few people know about this function of the ANGLE GRINDER! Brilliant Invention!

It is advisable to tin the tracks before soldering the parts, so their conductivity will improve. The microcircuit can be installed in a socket, then it can be removed from the board without any problems. First, resistors, diodes, small capacitors are soldered, and only then the largest components. After completing the assembly of the board, it is imperative to check it for correct installation, ring the tracks, wash the remaining flux.

Installation of the regulator in the cavity of the angle grinder housing

The electronic device, assembled separately from the angle grinder, is encased in a dielectric material as all components are energized. A portable electrical outlet with a cable is fixed to the body. The handle of the variable resistance resistor is brought out. The regulator is connected to the mains, and the tool to a portable power outlet.

How to turn off, remove the voltage sensor

In the next video, the author’s speed regulator has failed on one of the models of the angle grinder. Attempts to repair it were unsuccessful. The author describes how you can remove a broken regulator and assemble an electrical circuit without it (just connect the stator windings directly through the switch). the angle grinder will only function at maximum speed.

How to assemble a regulator circuit with your own hands

The simplest power regulator, suitable for an angle grinder, soldering iron or light bulb, is easy to assemble with your own hands.

How to connect the device to an angle grinder, options

The connection of the regulator depends on which type of device is selected. If a simple circuit is used, it is enough to mount it in the mains supply channel of the power tool.

Why is an angle grinder low speed?

The built-in disc speed control allows you to delicately handle materials such as plastics or wood. At low revs, the comfort and safety of work is increased. This function is especially useful in electrical and radio installation practice, in car services and restoration workshops.

In addition, there is a strong belief among professional users of power tools that the simpler the device is, the more reliable it is. And the additional service “stuffing” is better to take out of the power unit. In this situation, the repair of equipment is greatly simplified. Therefore, some companies specifically produce remote individual electronic controls that are connected to the power cord of the machine.

How to make a do-it-yourself angle grinder speed controller

If you have an old angle grinder in your arsenal, do not rush to write it off. Using a simple electrical circuit, the device can be easily upgraded by adding the function of changing the frequency of revolutions. Thanks to a simple regulator, which can be assembled with your own hands in a few hours, the functionality of the device will increase significantly. By reducing the rotational speed, the angle grinder can be used as a grinding and sharpening machine for various types of materials. New possibilities appear for the use of additional attachments and accessories.

Installing a homemade board

There are no ready-made installation recipes. Anyone who decides to equip an angle grinder with a regulator positions it according to their purpose and tool model. Someone inserts the device into the handle of the holder, someone into a special additional box on the case.

The space inside the angle grinder body may vary from model to model. Some have enough free space to install a control unit. In others, you have to bring it to the surface and fix it in a different way. But the trick is that, as a rule, there is always a certain cavity in the back of the instrument. It is designed for air circulation and cooling.

Usually, this is where the factory speed regulator is located. A DIY scheme can be placed in this space. To prevent the regulator from burning out, the thyristors should be installed on the radiator.

Assembly order

-

An electrical circuit is assembled on a printed circuit board or surface-mounted.

Device manual

The basic rule when operating an angle grinder with a homemade speed controller is to observe the work and rest mode. The fact is that the engine operating at the “regulated” voltage is especially hot. When sanding at reduced speeds, it is important to take frequent breaks so that the collector windings do not burn out.

It is also highly discouraged to turn on the tool if the speed controller is set to a minimum. the undervoltage is not enough to spin the rotor, the collector lamellas will remain in short-circuit mode, and the windings will start to overheat. Unscrew the variable resistor to the maximum, then, turning on the angle grinder, reduce the speed to the desired value.

Observance of the correct order of switching on and adjustment will allow you to operate the angle grinder for an unlimited time.

In addition, it should be understood that the speed control on an angle grinder follows the principle of a water tap. The device does not increase the number of revolutions, it can only lower them. It follows from this that if the maximum passport speed is 3000 rpm, then when the speed controller is connected, the angle grinder will operate in a range lower than the maximum speed.

Attention! If the angle grinder already contains electronic circuits, for example, is already equipped with a speed controller, then the thyristor controller will not work. The internal circuits of the device simply will not turn on.

How to assemble an adjustment circuit?

The traditional speed control circuit is quite simple: phase-pulse unlocking of the triac, there are only a few details in it. However, it does not behave very stable, so a professional tool uses this principle in a complicated version, with feedback and overcurrent protection (U2008B and U2010B microcircuits).

Now there are more advanced options using PWM controllers. Their schemes are a little more complicated, but the main difficulties arise there during setup and assembly. Instruments (oscilloscope) may be required, and the ability to work with expensive parts that are afraid of static charges. In general, this is not for ordinary consumers.

Therefore, it is better to take the middle solution: a variant with a triac and a U2008 microcircuit, this circuit will only require correct assembly and inexpensive parts. A simple device, but it works just fine for a household tool.

Electronic unit in angle grinder

The electronic unit allows you to combine the speed controller and soft start into one whole. The electronic circuit is implemented according to the principle of pulse. phase control with a gradual increase in the opening phase of the triac. Angle grinders of different power and price category can be supplied with such a block.

How to assemble a regulator circuit with your own hands

The simplest power regulator, suitable for an angle grinder, soldering iron or light bulb, is easy to assemble with your own hands.

What is a speed regulator and what is it for

This device is designed to control the power of the electric motor. It can be used to adjust the speed of rotation of the shaft. The numbers on the adjusting wheel indicate the change in the rotational speed of the disc.

The regulator is not installed on all angle grinders.

Why is an angle grinder low speed?

The built-in disc speed control allows you to delicately handle materials such as plastics or wood. At low revs, the comfort and safety of work is increased. This function is especially useful in electrical and radio installation practice, in car services and restoration workshops.

In addition, there is a strong belief among professional users of power tools that the simpler the device is, the more reliable it is. And the additional service “stuffing” is better to take out of the power unit. In this situation, the repair of equipment is greatly simplified. Therefore, some companies specifically produce remote individual electronic controls that are connected to the power cord of the machine.

Step-by-step diagnostics of an electrician with a multimeter or a light bulb

When diagnosing and repairing the electrical part of the angle grinder, it is most convenient to use a multifunctional tester (abbreviated name. multimeter). If such a device is not at hand, then a screwdriver with an indicator or a light with two wires is suitable for some checks. During the repair process, the multimeter allows you to measure both the voltage and current values, and the resistance of the motor windings. The indicator and light can only show the presence or absence of voltage.

Circuit operation

The U2008B microcircuit is a voltage stabilized phase regulator. It offers a choice between soft start and speed stabilization. A signal from a current sensor is applied to pin 1 or, if a soft start is used, an electrolytic capacitor with a capacity of several microfarads is connected.