Replacing the omentum on the Patriot trimmer. Popular materials

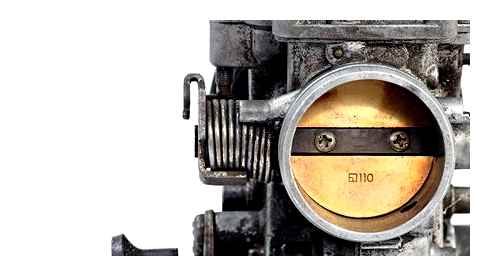

Repair of benzos, gasoline trimmers In order for the lawn mower to work properly and serves you for a long time, it is necessary to conduct a regular technical inspection, during which existing breakdowns or malfunctions can be detected, as well as those that may occur during future operation. The consequences of the failure of the lawn mower can be […]

Read more